The Real Reason Pulse-Jet Collectors Lose Performance Over Time

Pulse-jet collectors have a reputation for being simple, almost set-it-and-forget-it pieces of equipment. And its true… when they work well, they quietly protect your process, your people, and your permit. But when they do not, they let you know through rising differential pressure, short filter life, unstable airflow, and the constant sense that you are reacting instead of operating.

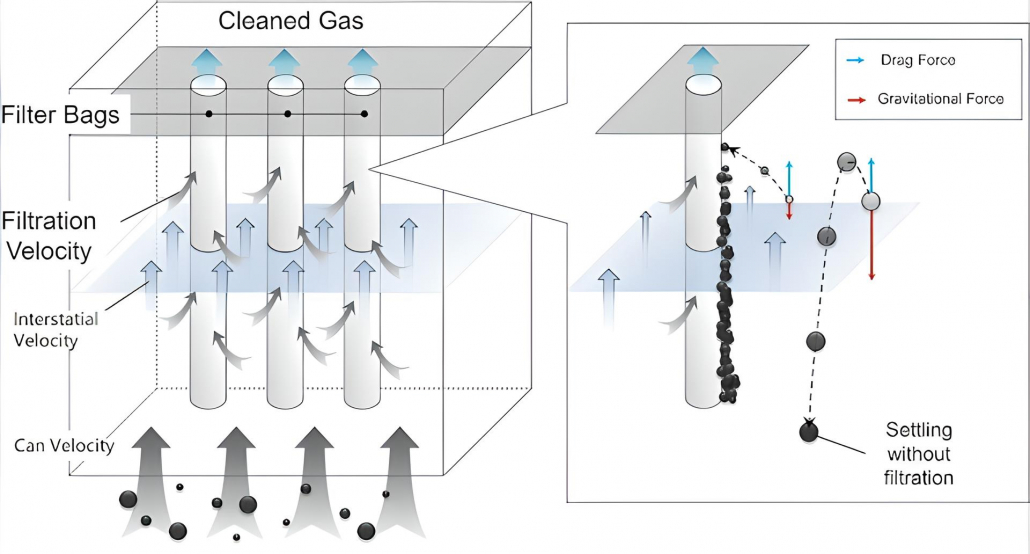

The first thing to understand is that pulse-jet cleaning does not just remove dust. Every pulse rearranges the dust cake that remains on the filter, and that dust cake is doing most of the real filtration work. In systems with high upward gas velocities, especially those handling fine or light dust, submicron particles can separate from the rest of the dust stream. Over time, they form a very dense layer on the bag surface. That layer increases airflow resistance and drives up differential pressure, even when the filters look visually clean.

If you are fighting high-pressure drop and frequent pulsing, this behavior is often the real culprit.

Why pulse sequence matters

Typical pulse-jet row cleaning sequence.

One of the most common setup mistakes is pulsing filter rows in simple numerical order. It feels logical, but it can actually work against you. When rows are cleaned one after another, fine material can migrate toward the rows that were just pulsed. The dust cake never has a chance to stabilize, and the system ends up cleaning more often than necessary.

Staggering the pulse sequence changes that dynamic.

Recommended pulse-jet row cleaning sequence.

By separating recently cleaned rows from those that are still loaded, the dust cake forms more uniformly. Filtration improves, pressure drop becomes more predictable, and cleaning frequency often drops. In many cases, filter life improves as well, without changing filters, valves, or fans.

Getting pulse timing and frequency under control

Pulse duration is another area where small adjustments make a big difference. For standard high-pressure, low-volume pulse-jet collectors, pulses should be short and crisp. The goal is to create a shock wave inside the bag, not to inflate it for as long as possible. In most applications, a pulse duration between 0.10 and 0.15 seconds is effective, assuming it aligns with the filter and valve manufacturer’s recommendations.

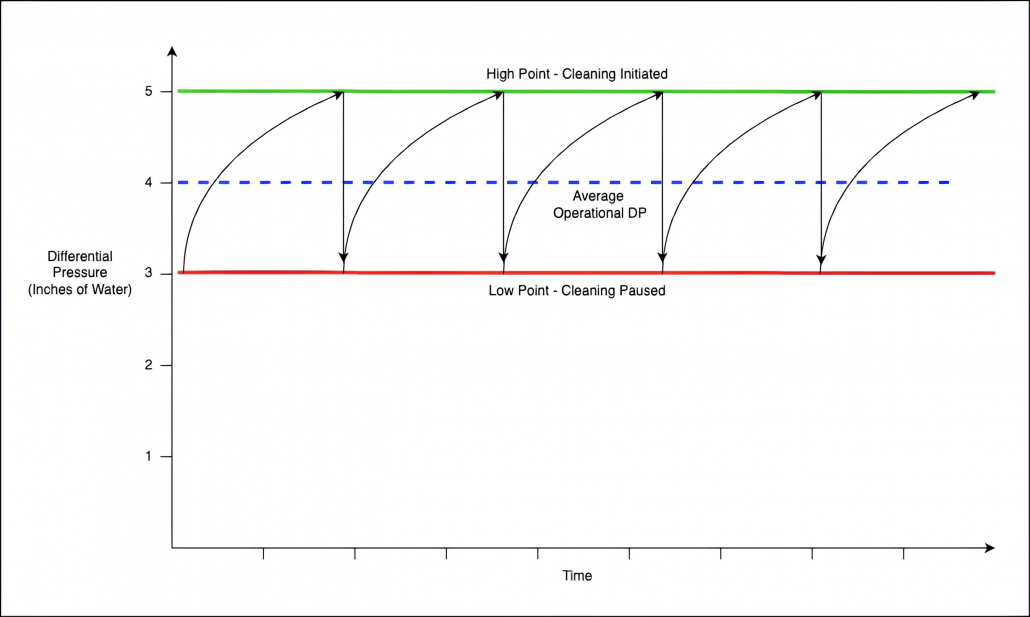

Cleaning frequency deserves just as much attention. Pulse too often and you destroy the dust cake you are trying to maintain. Pulse too slowly and differential pressure climbs until airflow and capture suffer. In real-world systems, pulse intervals can range from one second to 30 seconds or more. The most reliable control variable is differential pressure across the collector. Many pulse-jet systems operate best with an average pressure drop in the range of 3 to 6 inches of water column, depending on the filter media and process conditions.

Clean-on-demand control and compressed air

Clean on-demand systems help stabilize all of this.

In a clean-on-demand mode, the cleaning system will activate once the collector differential pressure rises to the set HIGH point and will continue cleaning until enough dust cake has been removed to drop the differential pressure to the set LOW point.

Using a differential pressure switch, such as a Photohelic gauge, allows the collector to clean only when needed. The system begins pulsing at the high pressure set point and stops when it cleans down to the low set point. Keeping those set points within about 0.5 to 1.0 inch of water column of each other reduces compressed air usage and prevents unnecessary cleaning.

Just as important, pulse frequency should never exceed the recovery capability of the compressed air system. Each pulse should fire only after header pressure has fully recovered so that every row is cleaned with the same force. Header recharge time depends on compressor capacity and the size of the feed line to the header tank. In many installations, a 1.5-inch feed line is typical, but undersized piping can quietly undermine pulse effectiveness.

When pulse-jet problems are mechanical, not settings-related

Not all pulse-jet problems are control-related. Pulse valves themselves are frequent troublemakers. Diaphragm failure, dirt, oil, or moisture entering the valve body can all reduce cleaning energy. Disassembling and inspecting valves is often the fastest way to confirm the issue. Before doing that, it is worth checking that tubing and fittings between the pulse valves and solenoid valves are intact, leak-free, and correctly connected.

The electrical side matters too. Timer boards and solenoid pilot valves should be verified before deeper mechanical work begins. A control fault can look exactly like a compressed air problem if you are not careful.

Can velocity and why light dust is unforgiving

Can velocity is the vertical gas velocity throughout the housing, above the hopper level but before reaching the bottom of the bags.

Pulse-jet collectors typically clean online and often have inlets below the filters. In these designs, can velocity becomes critical, especially when handling light-density dust at or below 35 lb/ft³. Excessive can velocity, often above 250 to 300 feet per minute depending on the dust, can drive high pressure drops and persistent re-entrainment.

Increasing available filter area is one way to address this. Pleated filters provide more surface area than traditional bags, allowing fewer elements and more open airflow area. That directly reduces can velocity. In some cases, relocating the inlet above the bottom of the filters can also reduce turbulence and re-entrainment.

The quiet damage caused by cages and poor fit

Bent or damaged cages cannot properly support the bag, leading to uneven flexing and premature failure. In corrosive environments, rust and pitting abrade the fabric during every cleaning cycle. Even sharp edges on cage bottom pans can cause long-term damage that only shows up once bags begin to fail.

Installation details that prevent repeat failures

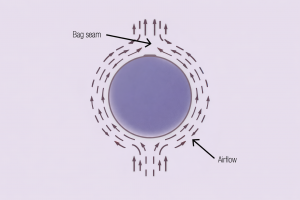

In pulse-jet collectors, all bag seams should face the same direction.

Proper installation plays a major role in filter life. Bag seams should all face the same direction. This simple practice provides a consistent reference point when diagnosing failures. If bags consistently fail opposite the seam, inlet abrasion is often the underlying cause. Without that reference, patterns are easy to miss.

Bag-to-cage fit is just as critical. Filters that are too loose or too tight limit collection efficiency and shorten service life. Allowing the correct amount of excess fabric, often referred to as the pinch, depends on the fabric type and must be matched to the cage dimensions.

Five fundamentals that define baghouse performance

Even when pulse settings are dialed in and filters are installed correctly, many baghouses struggle because of basic design and operating choices made years earlier.

1 – Use an inlet design that is right for your application.

Using pleated filters is often the most effective way to bring an overloaded system back into balance.

2 – Improve the air-to-cloth ratio. It defines how much air is handled per unit of filter area, and when it is too aggressive, problems follow quickly. High pressure drop, poor cleaning, and weak capture at pickup points are common symptoms.

Pulse-jet collectors can operate at higher air-to-cloth ratios than shaker or reverse-air units, but there are still practical limits.In many ambient temperature pulse-jet applications, ratios above about 6 to 1 push the system toward instability. High-temperature systems usually need to be more conservative. Increasing filter area, including the use of pleated filters, is often the most effective way to bring an overloaded system back into balance.

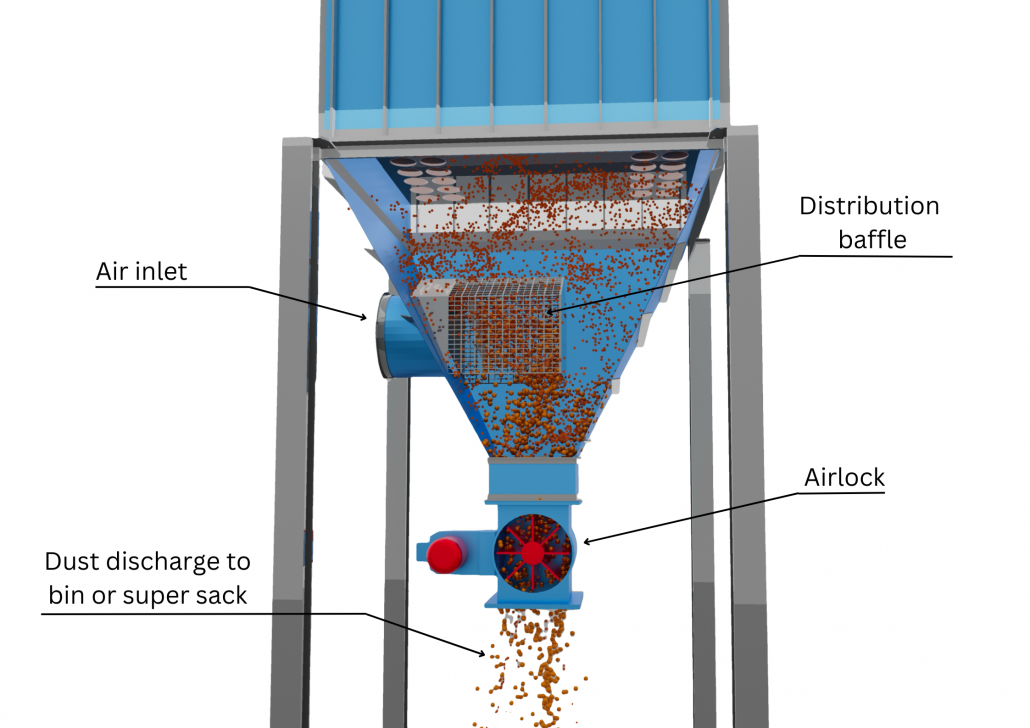

3 – Don’t use the hopper for material storage. They are designed to allow dust-laden air to enter the collector and to discharge collected material continuously.

When a hopper is used for material storage, dust can build up and re-enter the airstream, abrading the lower portions of the filters and shortening their life. Even without intentional storage, dust buildup on hopper walls or bridging over the outlet can cause re-entrainment or sudden slugs of material. Continuous dust removal using an airlock or dump valve helps keep the system stable.

4 – Make sure that baghouse access doors seal properly. Poorly sealed doors allow air leakage, dust leakage, heat loss, and condensation. That condensation can lead to filter failure and severe corrosion. Door seals are inexpensive compared to the problems they prevent, but they need regular inspection. Ensuring positive contact between the seal and the door panel goes a long way toward maintaining consistent operation.

Stability is rarely accidental

A pulse-jet collector that runs well is usually the result of thoughtful pulse settings, sound mechanical condition, good airflow design, and attention to operational details that are easy to overlook until they start causing trouble. When those fundamentals are in place, the system stops demanding attention and starts doing what it was meant to do, quietly and reliably.

And if you suspect your collector could do better, there are often more opportunities hiding in plain sight. A short conversation with experienced baghouse specialists can uncover practical adjustments and design improvements that are specific to your process, not just textbook recommendations.

System-wide testing is how you catch those problems early. Done correctly, testing tells you whether your dust control system is still doing the job it was designed to do, and whether it can safely handle today’s production demands.

System-wide testing is how you catch those problems early. Done correctly, testing tells you whether your dust control system is still doing the job it was designed to do, and whether it can safely handle today’s production demands.

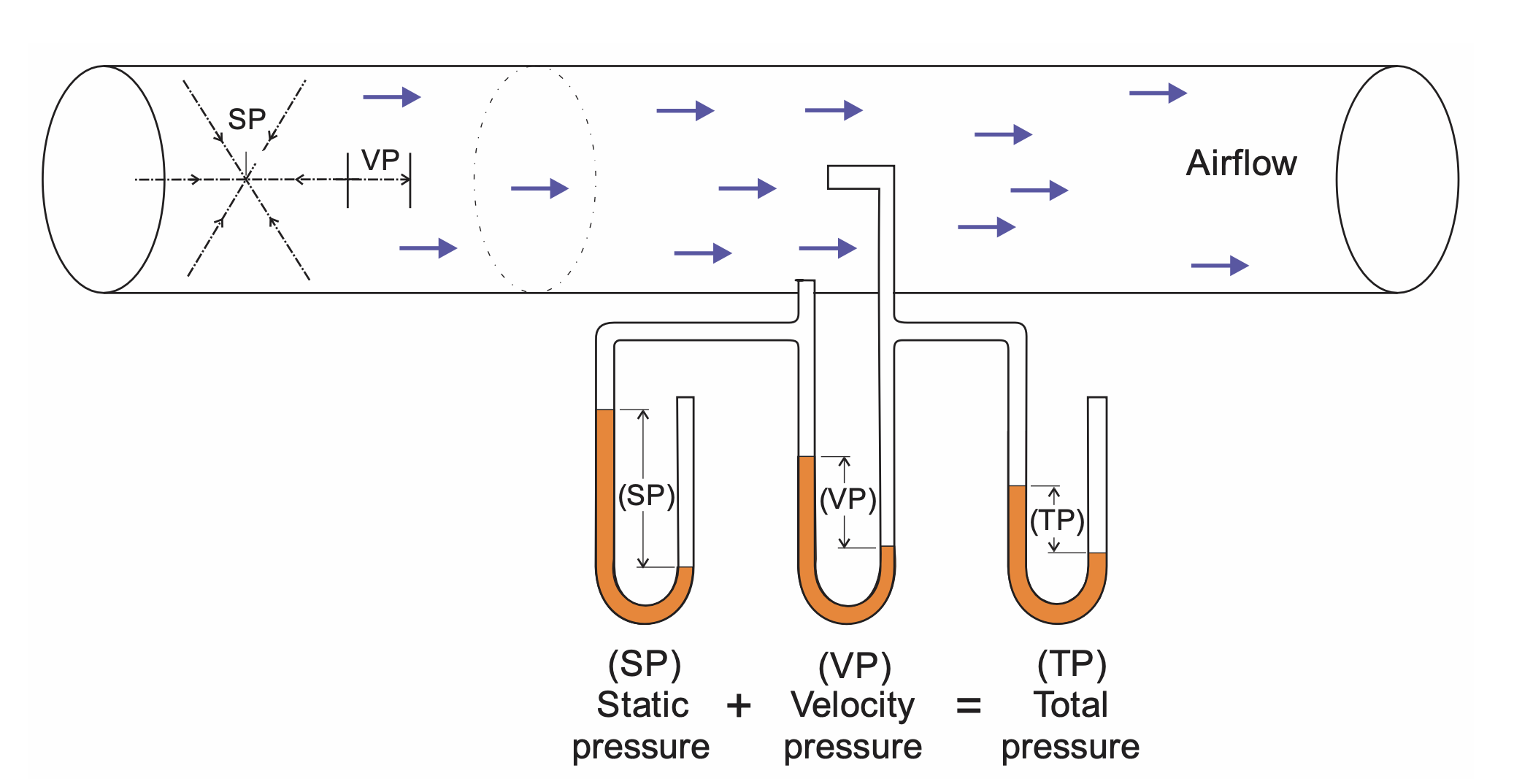

Airflow inside a duct is never uniform. Measuring velocity at a single point gives you misleading data. Proper airflow measurement requires traversing the duct cross-section. Divide the duct into equal areas and measure velocity pressure at the center of each area. The smaller the areas, the more accurate the result.

Airflow inside a duct is never uniform. Measuring velocity at a single point gives you misleading data. Proper airflow measurement requires traversing the duct cross-section. Divide the duct into equal areas and measure velocity pressure at the center of each area. The smaller the areas, the more accurate the result.

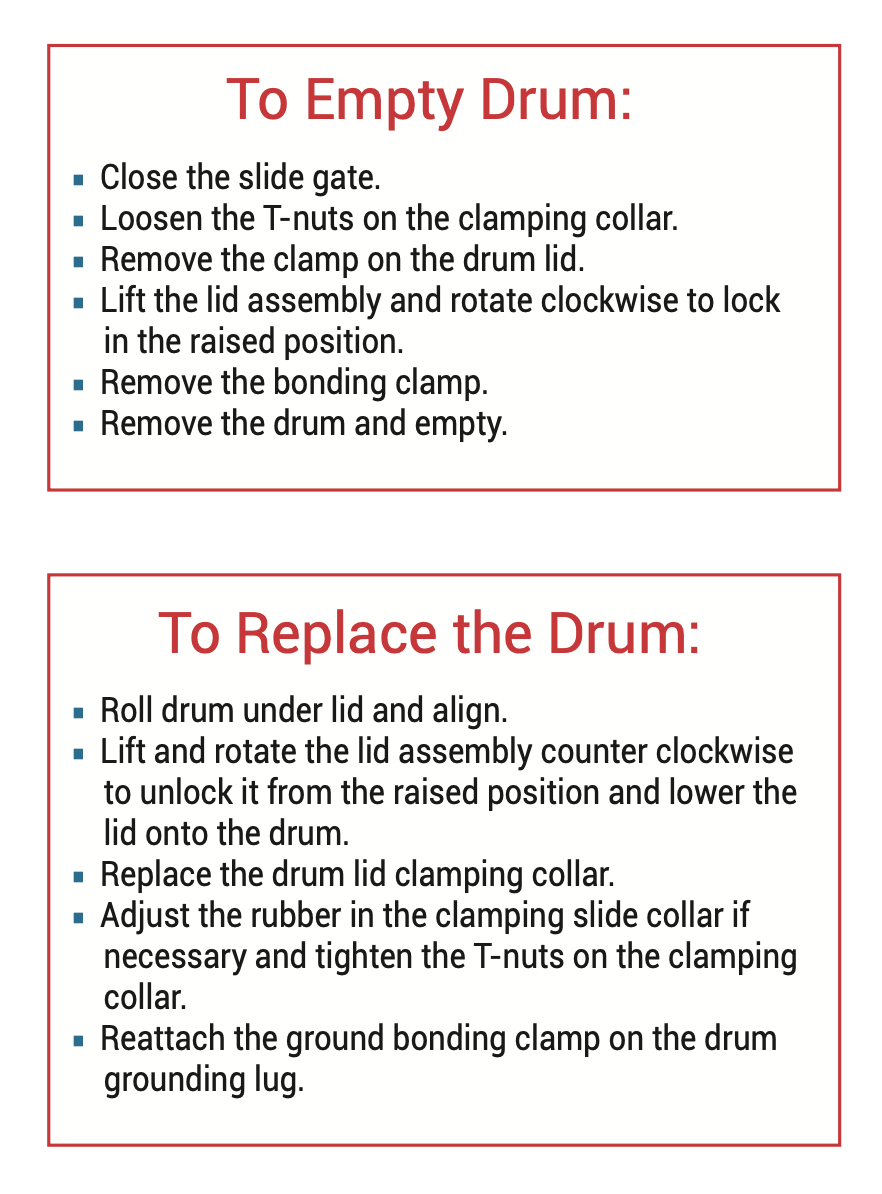

Safe operation is essential. Operators should wear appropriate safety shoes and protective gloves when using the hydraulic lift. The lift should only be used on a firm, level surface and should never be overloaded. It is not intended to be used as a lifting platform or step, and care must be taken to keep hands and feet clear during operation. The surrounding work area should always be checked for overhead obstructions or other hazards.

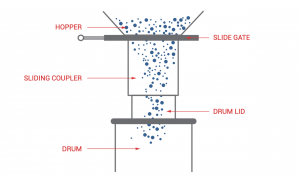

Safe operation is essential. Operators should wear appropriate safety shoes and protective gloves when using the hydraulic lift. The lift should only be used on a firm, level surface and should never be overloaded. It is not intended to be used as a lifting platform or step, and care must be taken to keep hands and feet clear during operation. The surrounding work area should always be checked for overhead obstructions or other hazards. Raptor Drum kits can be used with a wide range of dust collectors that are designed to discharge into a drum. They can also be retrofitted to replace non-compliant drums, flex hose arrangements, airlocks, or other discharge devices on both new and existing systems. Available discharge sizes include 10, 12, 14, 16, and 18 inches, allowing the drum kit to be matched to many common collector configurations.

Raptor Drum kits can be used with a wide range of dust collectors that are designed to discharge into a drum. They can also be retrofitted to replace non-compliant drums, flex hose arrangements, airlocks, or other discharge devices on both new and existing systems. Available discharge sizes include 10, 12, 14, 16, and 18 inches, allowing the drum kit to be matched to many common collector configurations.

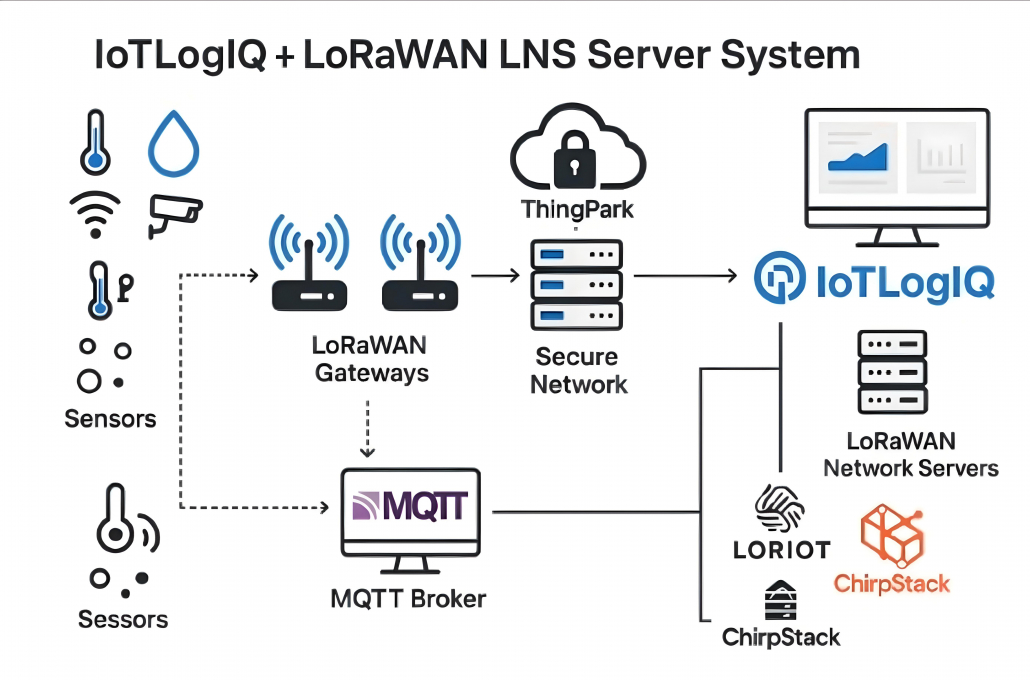

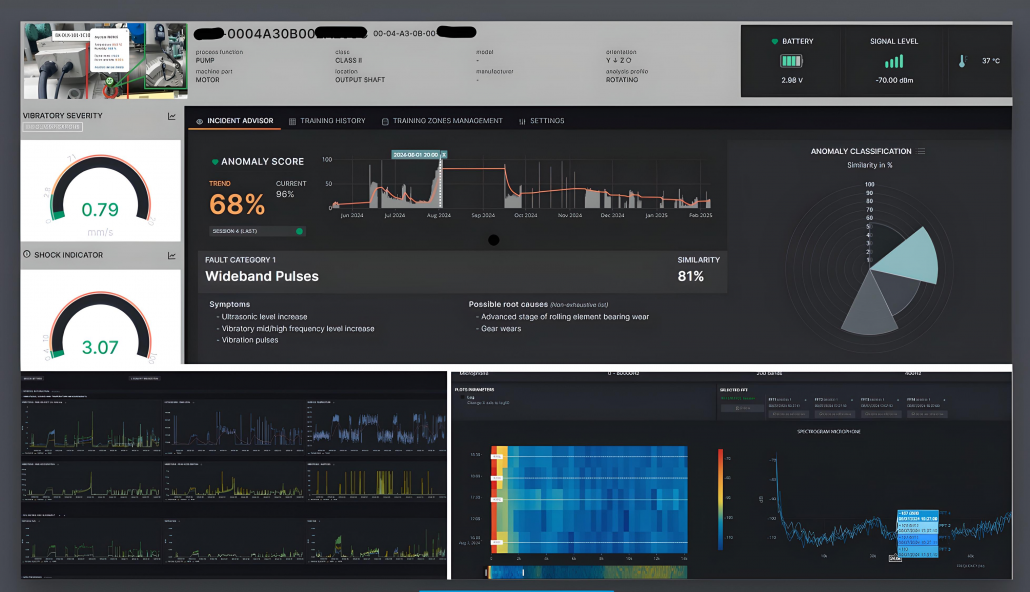

If you’re considering bringing IoT into your dust collection systems or broader plant operations, we’re here to help. Our team works directly with facilities to design practical, cost-effective sensor strategies that deliver real gains in reliability, maintenance, and compliance. If you have questions about anything covered in this FAQ or want to explore what this technology could look like in your facility, reach out to us anytime. We’re happy to walk you through options, share examples from similar plants, and offer a free consultation to evaluate how IoT can support your goals.

If you’re considering bringing IoT into your dust collection systems or broader plant operations, we’re here to help. Our team works directly with facilities to design practical, cost-effective sensor strategies that deliver real gains in reliability, maintenance, and compliance. If you have questions about anything covered in this FAQ or want to explore what this technology could look like in your facility, reach out to us anytime. We’re happy to walk you through options, share examples from similar plants, and offer a free consultation to evaluate how IoT can support your goals.

✅ Fan motors

✅ Fan motors

⁉️ Will it connect easily to your equipment?

⁉️ Will it connect easily to your equipment?

Interstitial velocity refers to the upward velocity of air moving through the open spaces between the filter bags inside a dust collector.

Interstitial velocity refers to the upward velocity of air moving through the open spaces between the filter bags inside a dust collector.