How Can I Tell When I Need to Replace My Baghouse Filters? (FAQ Series)

"Why should I replace my baghouse filters?"

Severely caked baghouse filters—when dust buildup becomes excessive, it restricts airflow and reduces system efficiency. Time to replace them!

There are two main reasons why this can happen:

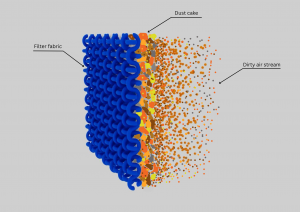

The filters become compromised. Over time, filters can develop holes or tears, allowing dust-laden air to pass through unfiltered. This can lead to increased emissions and reduced system efficiency.

The filter media becomes clogged. As dust accumulates, it embeds deep within the filter fabric, restricting airflow and making it harder for your system to operate effectively.

"It’s been a few years since we last changed our baghouse filters. How do I know if I need to replace them?"

Baghouse filters typically last 1-3 years, but this varies based on operating conditions. Some can last longer with proper maintenance, while others wear out sooner in more demanding environments.

Here are some clear signs that it’s time for a replacement:

-

Filters that have reached the end of their service life and are blinded cause the suction at the pick up points to become weaker, increasing the dust inside the facility

✧ Filters are no longer cleaning effectively. If dust is deeply embedded in the fabric, even strong compressed air pulses won’t clean them. The recommended differential pressure is usually between 3″ and 5″ inches of dP. If even after the cleaning the differential pressure stays consistently high, this means that your system is working harder but collecting less dust.

-

✧ Dust is leaking from the system. If you notice dust escaping into the air, your filters may have holes or tears. This compromises air quality, efficiency, and potentially puts you out of regulatory compliance.

-

✧ Reduced suction at pickup points. If dust isn’t being captured as effectively as before, clogged filters might be restricting airflow. This can cause weaker suction, higher fan energy consumption, and inefficient dust collection.

Read more about this in the article: Should I Change My Filters on a Schedule?

"Are there other factors that affect when I should replace my filters?"

-

The three key entities involved in dust emission regulations are OSHA, NFPA and AHJ

♦️ Air quality regulations – Staying compliant with local, state, and federal air quality standards is critical. In industries like pharmaceuticals or food processing, failing to meet these standards can result in fines or production shutdowns.

.

.

-

Some types of fine powders or sticky materials tend to clog filters much faster than dry, free-flowing dust

♦️ Type of dust collected – Some particulates, like fine powders (e.g., flour, cement, carbon black) or sticky materials (e.g., resins, oils, or chemical dusts), tend to clog filters much faster than dry, free-flowing dust like wood or grain dust.

- .

-

♦️ Moisture levels – Humidity and condensation can cause dust to cake up and blind the filters. This is common in cement plants or foundries where temperature variations cause moisture to form inside the collector, leading to hard-packed dust that won’t release during cleaning cycles.

- .

-

Baghouse filters damaged by a spike in high temperatures

♦️ Operating temperatures – If temperatures fluctuate and drop below the dew point, moisture buildup can damage filters. This often happens in applications with hot gas streams, such as asphalt plants or power generation, where gases cool too quickly and lead to condensation that shortens filter life.

- .

-

♦️ System design and workload – If your dust collector was undersized or is handling higher dust loads than originally intended, filters may need replacement more frequently. For example, if a woodworking shop expands its production but doesn’t upgrade its dust collection system, the filters will wear out faster due to increased sawdust accumulation.

Read more about this in the article: How Often Should Baghouse Filters be Changed?

"Should I replace all filters at the same time?"

Yes, replacing all filters at once is recommended for consistent airflow and efficiency. Mixing old and new filters can create airflow distribution problems, causing some filters to clog faster than others. If you must replace only a few filters, ensure it’s less than 5% of the total filters to avoid imbalances.

Regular inspections and maintenance can help extend filter life and keep your dust collection system running efficiently. If you’re unsure whether your filters need replacing, reach out to a dust collection expert for an assessment.

"Can I extend the life of my baghouse filters?"

Absolutely! With the right maintenance, you can significantly extend the life of your baghouse filters.

Here are some of the best ways to do that:

-

✔ Optimize Your Cleaning Cycles – More cleaning doesn’t always mean better performance. If your system is pulsing too frequently, it can wear out filter bags prematurely. Instead of running the cleaning system on a set timer, consider using a differential pressure-based cleaning system, which only pulses when needed. For example, we recently worked with a metal fabrication plant that switched from a fixed cleaning cycle to an on-demand system and saw their filter service life nearly double!

-

✔ Ensure Proper Installation – A poorly installed filter can leak from the start. If the snap band filters aren’t seated correctly, dust can bypass the filter, leading to even more problems.

-

✔ Control Moisture and Temperature – If your operation has high humidity or temperature swings, moisture can cause dust to cake onto filters, making them nearly impossible to clean. This is common in cement plants or food processing facilities where steam or moisture is present. Using a pre-coat agent (like limestone powder) or heating the air before entering into the collector above the dew point can help keep filters from getting clogged with wet, sticky dust.

-

✔ Choose the Right Filter Media – Not all filters are created equal! If your process handles abrasive dust (e.g., sandblasting operations), high temperatures (e.g., asphalt plants), or oily particles (e.g., metal machining), you might need specialized filters.

- Read Article: Filter Medias Explained

-

Simple monthly inspections can help catch early signs of wear, like small leaks, excessive pressure buildup, or unusual dust accumulation.

✔ Perform Regular Inspections – Don’t wait for a major problem to check your filters. Simple monthly inspections can help catch early signs of wear, like small leaks, excessive pressure buildup, or unusual dust accumulation.