Often the hardest part about purchasing replacement parts for your dust collection system is identifying what kind of dust collector you have. Use this guide to quickly learn how to identify which dust collector style you have and get your quotes faster.

Knowing Your Dust Collector is Key To Getting Better Quotes For Replacement Parts and Services

When a potential customer calls or emails us requesting pricing for replacement filters, parts, or services for their dust collection system, we often run into the same problem. “Can you tell me what kind of dust collector you have?” we ask, followed by “um…I don’t know.” Yes, it is quite common for customers to not know what kind of dust collector they have, let alone the specs for their filter bags, pulse valves, control boards, etc.

Knowing the details about your dust collection system is vital for obtaining information and pricing for products/services such as:

- 🔹 Replacement Filters: Bags, cartridges, pleated elements; filter cages

- 🔹 Replacement Parts: Pulse valves, control boards, door gasket material, leak testing powder/lights, venturi, mounting hubs, etc.

- 🔹 Service Work: Filter replacement services, refurbishing of existing dust collectors, training courses, technical inspections, etc.

- 🔹 Engineering Services: Replacing or modifying an existing dust collector, changing filter materials, upgrading to pleated filter elements, etc.

At times, customers may have some obscure part numbers they’ve pulled off a rusty metal plate on the collector… sadly, these almost never result in any meaningful information, since most dust collector OEMs either assign random serial/part numbers to their units or do not provide reference sheets for their products. As such, maintenance personnel, purchasing agents, or others assigned to get pricing for these items do not have the necessary information for us to determine what they need.

With this in mind, we have prepared the following guide to identifying the various types of dust collector styles and configurations.

For determining what kind of replacement filter bags your baghouse requires, please see the article: How To Choose The Correct Dust Collector Filter

Main Types of Fabric Dust Collectors

All fabric filters operate on the same basic principle of passing dust-laden air through a fabric material to capture and remove particulates. The main differences between various dust collectors are the way the filters are cleaned and the type of filters they use.

- NOTE: Fabric filter dust collectors (i.e. baghouses) are the most common kind of dust collection system used in industry. Electrostatic precipitators, wet scrubbers, and cyclone collectors are also used, often in conjunction with fabric filter units. For this article we will consider only fabric filter dust collectors.

The three kinds of dust collectors according to cleaning styles are:

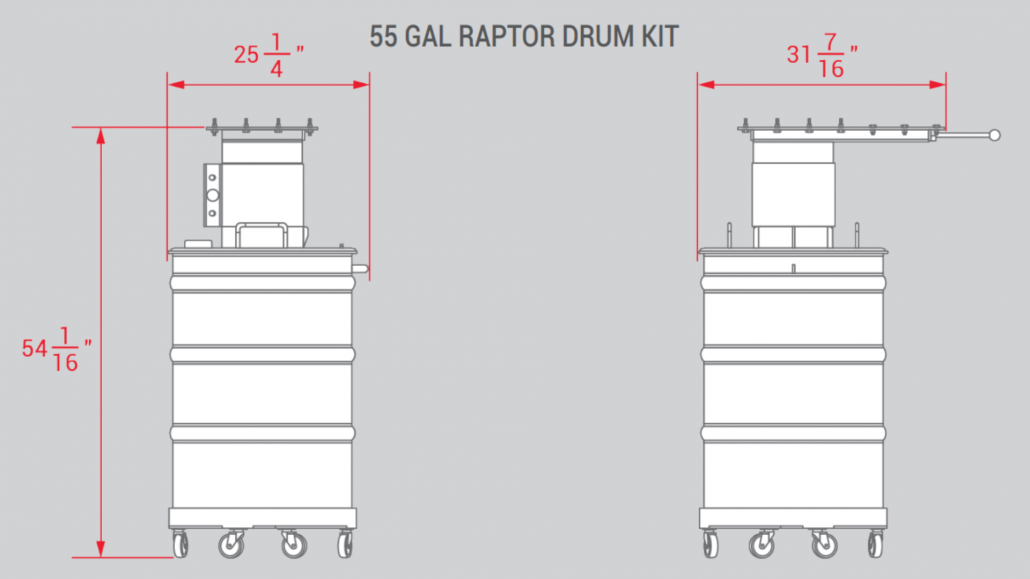

- 🔸 Pulse Jet – Bags are suspended from a tubesheet at the top of the unit and cleaned by blowing compressed air into the filters from above. Bags are supported by metal wire cages. Cleaning can be accomplished while the unit is running (i.e. online cleaning) using blasts of compressed air directly into rows of bags. The vast majority of units manufactured in the last 30 years are pulse jets. Included in this style are Bin Vents. These small units are basically just small pulse jets with no hopper that dump directly back into the storage vessel when pulsed. These units can be converted to pleated filters.

- 🔸 Shaker – Bags are attached to a rack or tubesheet shaken by motor(s) to release buildup dust cake and clean the bags. New installations of these systems are uncommon due to inefficiency and high cost of use.

- 🔸 Medium Pressure Reverse Air – In these systems, bags attach to a tubesheet with a snap band top and then use a metal wire cage for support. Bags are cleaned by a rotating cleaning arm that directs a constant steam of clean air down into each bag as it rotates. It uses essentially identical bags as a top load pulse jet; some use oval-shaped bags in place of round bags/cages. These can also be converted to pleated filters.

- ► NOTE: Medium-pressure reverse air systems (Such as Donaldson RF series) while not as widely-used as pulse jets, are still found in many industries. These units use bags nearly identical to top-load pulse jet bags.

- 🔸 Low Pressure Reverse Air – In these systems, bags are attached at the bottom to a tubesheet with large mounting hubs or thimbles, and then suspended from chains and conical springs or “J-Rods” with conical springs and then tensioned from above. Bags are cleaned when the dirty air inlet is closed and a secondary cleaning inlet is opened, then a second system fan (reverse air fan) blows air back into the baghouse from the top, and creates positive pressure collapsing the bags and causing the dust cake to fall off into the hopper. These are almost always very large units (500+ bags), compartmentalized to allow for continuous operation (cannot clean online), and found on foundries, mills, boilers, etc.

Pulse jets account for the vast majority of filters in use today. For that reason, let’s examine the various differences between pulse jet styles.

Identifying Variations of Pulse Jet Dust Collectors

View from underneath a tubesheet in a bottom load dust collector. Note the fixed venturi and mounting hubs where the bags and cages are attached.

- 🔵 On Bottom Load Dust Collectors (or bottom entry) units, the dirty air plenum is accessed through a door or hatch on the side of the unit (usually near the hopper break) with a walkway inside. The bags are attached to mounting hubs or thimbles on the underside of the tubesheet using a bag clamp (i.e. hose clamp). Replacing the filters requires the technician to enter the dirty side and release the clamp at the top of the filter and then remove the dirty filter and cage from the unit. These units typically take raw edge top, disk bottom bags, and split collar cages. The cages go inside the bag and then the excess fabric is folded over the edge of the cage, and then pushed up onto the mounting hub/thimble and then secured with a clamp.

Real-life example of a top load pulse jet dust collector with walk-in plenum. Notice the doors on the catwalk.

- 🔵 Top Load Dust Collectors (or top entry) permit access from above the tubesheet, on the clean side of the baghouse, usually by removing a top hatch/door and then stepping down onto to the tubesheet. The filters go down into the tubesheet hole from above and then are secured into the holes by either a snap band or use some kind of hold down hardware.

Some top-load units have an enlarged clean air plenum that allows technicians to walk in and remove the bags and cages entirely within the structure. These are called Walk-In-Plenum Top-Entry baghouses. Aside from the enlarged clean air plenum, these units are identical to top hatch/top-entry units. Due to the limited overhead clearance, these units may require two-piece cages to be used.

Top load style units almost always take snap band bags or a variation. Common cage designs include rolled top flange or flat flange. Some cages also have a separate venturi that drop into place, or are part of the cage top. Top entry units can also use pleated filter elements specifically designed for top load units.

Now that you have determined your style of pulse jet baghouse. Next, let’s examine the filters and cages to determine which kind you need.

Identifying The Different Filter, Cage, Cartridges, and Pleated Filter Variations

Next, you must identify the specifics of your filter bags and cage design. Many think that there are “standard” baghouse filters and that all they need is to mention a part number or a make of a baghouse, and the specs can be “looked up” and found. The reality is that in almost all cases, a detailed bag spec is required to get a proper quote.

Generally, to receive an accurate quote for dust collector filters requires the following specs:

✅ Dimensions (length & diameter)

- ► Flat width (most accurate measurement possible for a round bag)

- ✅ Top/Bottom Design

- ✅ Fabric

- ✅ Treatment/Finish (if any)

- ✅ Less-common special items

- ► Grounding wire

- ► Anti-collapse rings (reverse air only)

- ► Center or bottom wear strip (for two-piece cages or high abrasion applications)

Read more: How to Measure Your Baghouse Filters & Cages

.

The most common Top/Bottom Construction Styles according to baghouse style:

Top Load Baghouses – Common Bag/Cage Combos

- 🔵 Filter Bag: Snap band top, disk bottom

- ► May include additional wear strip at the bottom of the bag or in the middle (two-piece cages)

- 🔵 Cage: Rolled top, pan bottom

- ► Drop-in venturi or integral venturi

- ► Two-piece cages more common for Walk-In-Plenum variations

Bottom Load Baghouses – Common Bag/Cage Combos

- 🔵 Filter Bag: Raw edge top, disk bottom

- 🔵 Cage: Split collar (rolled band) normal or high groove, rolled flange (rolled band), flat flange, top, pan bottom

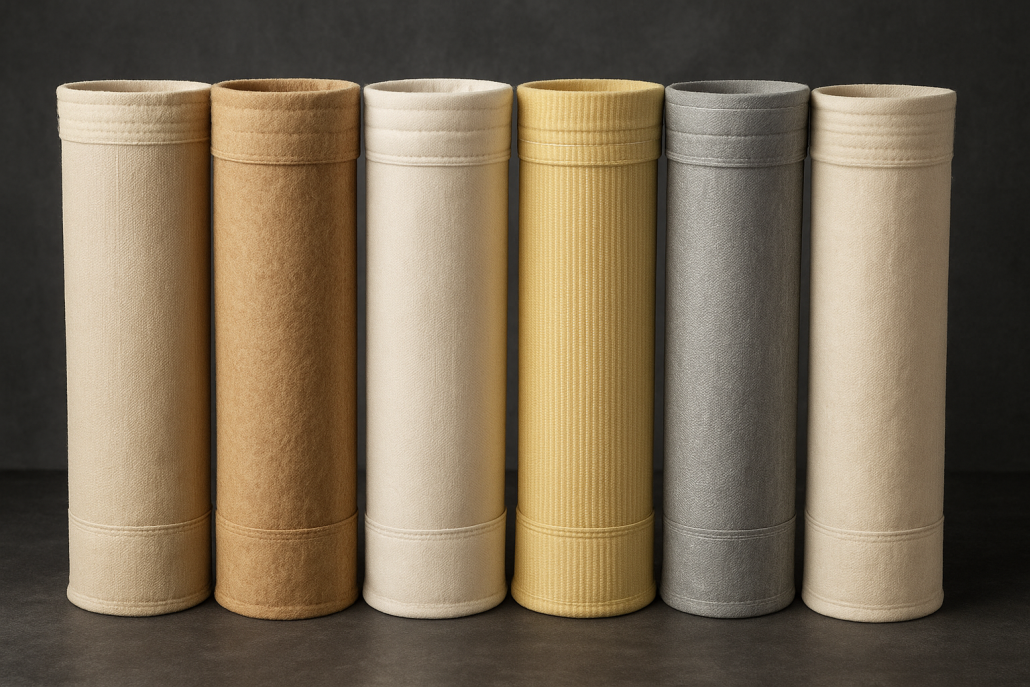

Selection of Filter Fabrics and Treatments

This depends on what material is being handled and air conditions inside the system (i.e. temperature, presence of acid/alkali gases or other reactive chemicals, etc. Cost is also a factor as some more resilient fabrics would be cost-prohibited in certain applications.

- 🔶 Low-Temperature Fabric Materials (250F or less) – Polyester (PE), Polypropylene, Cotton, Acrylic and Nylon

- 🔶 High-Temperature Fabric Materials (250F – 500F) – Aramid (Nomex), Fiberglass, PPS, P-84, PTFE (not to be confused with PTFE coating/membrane)

- Food Grade fabrics also exist for applications requiring FDA-approved materials.

- 🔶 Treatments/Finishes and Membranes are used to increase resistance to certain conditions or compounds. Common treatments included humidity/moisture (hydrophobic), oils and hydrocarbons (oleophobic), acid resistance, glazed, singed, egg-shell, PTFE treatment (not membrane) and others.

- ► A very special kind of treatment is PTFE membrane, which imparts higher collection efficiencies, easier dust cake release (i.e. easier to pulse clean), and extends useful service life. Membranes do not require precoating and can be cleaned more forcefully than normal bags.

- 🔶 Certain less-common design features include:

- ► Hold-down hardware (used on older models to hold bags and cages to the tube sheet)

- ► Non-standard bottoms such as sown flat, open bottom, star-shaped, etc.

- ► Non-standard tops such as cord, double-beaded-snap band, hangers, grommets, etc.

While the majority of bags are round, there are some older units that used envelope, oval, or other oddly-shaped bags for one reason or another. If this is the case, a accurate measurements and/or photos and samples are required to duplicate.

The thickness of the tube sheet may be required when replacingsnap band bags and cages. Since this varies from manufacturer to manufacturer, it’s often best to verify this before sending your request for a quote. This is especially important when converting older bag and cage styles or when installing pleated filter elements.

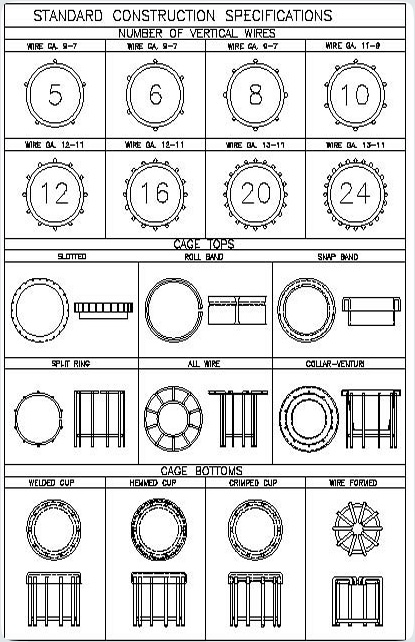

Baghouse Cages

Cage designs vary depending on the pulse jet variation. The main variables for baghouse cages are:

- 🔵 Dimensions (length x diameter)

- 🔵 Top/Bottom Design

- 🔵 Material

- ► Mild steel/carbon steel, galvanized, epoxy coated, or stainless steel (304, 318, etc.)

- ► Mild steel/carbon steel, galvanized, epoxy coated, or stainless steel (304, 318, etc.)

- 🔵 Number of vertical wires and horizontal wires

- ► Certain applications/fabrics call for more wires, e.g. fiberglass bags may take 12, 16, 20 or 24 wire cages)

- ► Rarely, cages require additional horizontal bracing. Most cages have horizontal wires every 6″

- 🔵 One or two-piece configurations

- ► Several different types of two-piece connection styles exist, the most common are “fingers” and twist-lock.

Read more: Top Load Snap Band Baghouse Filter & Cage Measuring Guide

Dust Collectors with Cartridges and Pleated Filters

Many cartridge collector manufacturers intentionally avoid giving detailed spec sheets, reliable part numbers, or designations to force the customer to continue to buy replacements from them.

In place of bags and cages, some dust collectors use cartridges. Identifying the correct replacement for these can be tricky. Many cartridge collector manufacturers intentionally avoid giving detailed spec sheets, reliable part numbers, or designations to force the customer to continue to buy replacements from them.

In many cases, cartridge collector manufacturers sell units at a loss and then make up the difference by charging high prices for replacement cartridges. While cartridge collector designs vary widely, it is always possible to get replacement cartridges from an aftermarket vendor at discounted rates compared to the original manufacturer.

Generally, to get a quote for a replacement cartridge often the following information is required:

- ✅ Any part, serial, or model numbers on the cartridge

- ✅ Collector manufacturer, serial/model numbers

- ✅ Detailed measurements (Inside diameter, Outside diameter, overall length, and width (ID, OD, OAL, and W respectively)

- ✅ Type of fabric (see above for differences in fabrics and treatments)

- ✅ Number of pleats in the fabric (at times pleat depth as well)

- ✅ Top and Bottom construction (open/closed, open/open, gasket types, etc.)

As with bags, the best option is to send a sample for us to duplicate. When this is not possible, a series of detailed photos, along with the measurements and information above, will ensure a compatible replacement is found.

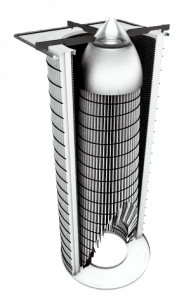

Pleated Filter Elements

A pleated filter element is NOT the same as a cartridge. Pleated filters often replace traditional bags and cages in both top load and bottom load pulse jet collectors.

In many cases, manufacturers design newer baghouses to use pleated filter elements (also called pleated bags) in place of standard bags and cages. Though similar, pleated elements differ from cartridges in both application and operation.

Generally, they are not suitable for high temperatures and excessively abrasive dust.

Pleated filter quotes require the same basic information as bag quotes, namely, dimensions, fabric/treatment, and baghouse style (bottom load or top load).

See the article Pleated Baghouse Filters: A Smarter, More Cost-Effective Solution!

Now You Can Get a Quote For Replacement Filters

Now you should be able to identify what kind of dust collector you have and what kind of filters it uses. This should enable you to gather the information needed for a pricing quote on replacement filters, or engineering services.

Now when you call in and ask for a quote you will be able to provide the needed information for our sales associates to help quote your filters and cages.

- 🔸 Baghouse.com Associate: “What kind of baghouse do you have?”

- 🔹 Your Answer: “We have a top-entry, pulse jet baghouse.”

- 🔸 Baghouse.com Associate: “What kind of filters and cages does it take?”

- 🔹 Your Answer: “The bags are snap band top, disk bottom, aramid (Nomex) with PTFE membrane, 6″ x 120″, with a 6.25” tubesheet hole, with a QTY of 400. The cages are rolled-top, with integral venturi, 12 vertical wires, made from galvanized steel, QTY 400. “

- 🔸 Baghouse.com Associate: “Excellent! I can get you pricing on that right away.”

Still confused after this article? It’s ok, that’s what we are here for. Give us a call at (702) 848-3990 or email us here and we will be happy to walk you through the process. And if all else fails, you can always send us a sample filter to examine and leave the rest to us.