Insufficient baghouse capacity is one of the most common problems our customers encounter. Some common indicators of insufficient capacity include high differential pressure and difficulty cleaning the dust collector. In many cases, a high pressure drop results in lost suction and reduced airflow throughout the system. Reduced suction and airflow mean that pickup points and collection hoods capture less dust at the source, allowing dust to settle and build up in the ductwork, which further reduces suction and airflow. Even if suction and airflow remain sufficient for the process, high differential pressure directly causes higher emission levels through the filter fabric and early bag failure due to increased airflow and more frequent cleaning.

Why Do Systems Lack Sufficient Capacity?

There are several reasons why a dust collection system may be under capacity. One of the most common is that system processes are changed without regard for dust collector design. Even if a system was correctly sized and designed at installation, production increases later on may be made without considering how they affect baghouse operation.

In other cases, systems are undersized from the start due to poor project planning, weak engineering, or deliberate decisions by sales reps, OEMs, or management to undercut competitors with a lower-priced system.

If you are currently dealing with an undersized system, there are several proven ways to increase capacity.

Five Ways to Increase Baghouse Capacity

💡#1 — Convert to Pleated Baghouse Filters and Increase Airflow

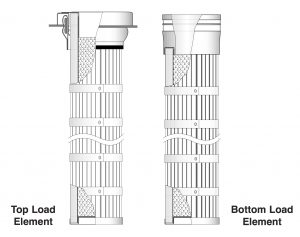

- Pleated filters can dramatically lower operating costs by increasing capacity, reducing emissions, and lowering electricity usage. These pleated filters improve on the design of traditional bags by packing more filter fabric into a smaller space, sometimes increasing the amount of filter media by as much as 700%.

- They are more efficient at removing particulate than traditional bags and often last up to twice as long. Pleated filters are designed to meet today’s high production demands and can replace existing bags and cages in most standard pulse jet baghouses without any modifications required.

- With the greater amount of filter media, operators can either:

- ✅ Keep the airflow the same, which reduces the air-to-cloth ratio and improves performance and filter life.

- ✅ Increase airflow to boost baghouse capacity, possibly allowing for the combination of several dust collection systems into one larger unit and in turn reducing operation costs.

💡#2 — Add Additional Modules

Most baghouse and cartridge collectors are designed with modular construction. That means the existing collector shell can be extended with one or more filter compartments. These new modules are bolted or welded onto the main collector housing and tied into the clean air plenum, hopper, and dust discharge system.

- By doing so, you’re expanding the collector’s filter area, which directly lowers the air-to-cloth ratio (ACR). This allows the system to handle higher airflow without needing full replacement. This upgrade also reduces stress on fans and bags.

- This is not necessarily an expensive upgrade. The biggest costs of a new system are the housing, hopper, support structure, fan, ductwork, and foundation. By adding modules, you’re keeping most of these in place. You’re only paying for the additional filter compartments, installation labor, and sometimes an upgraded fan if airflow requirements have increased.

💡#3 — Convert Older Shakers and Reverse Air Units to Pulse Jet Systems

- Many older dust collectors, such as shakers and reverse air units, can be upgraded into modern pulse jet systems instead of being replaced outright. This conversion involves retrofitting the collector housing with new tube sheets, installing pulse-cleaned filter bags with cages, and adding a compressed air manifold and control system.

- By doing so, you eliminate the need for mechanical shaking or continuous reverse airflow, which reduces moving parts, maintenance, and downtime. The result is a collector that can handle higher airflow at proper air-to-cloth ratios and provide much better cleaning while using the same basic housing and support structure. For plant managers, this is often a more economical and less disruptive option than buying a completely new system.

💡#4 — Install a Precleaner such as a Cyclone to Lessen Dust Loading

- Installing a precleaner, such as a cyclone, ahead of a baghouse is a smart way to reduce dust loading. A cyclone removes a large portion of the heavier particles before they ever reach the filter bags, which means the baghouse only has to handle the fine dust.

Cyclone dust collector upstream of a baghouse dust collector.

- This significantly reduces wear and tear on the bags, lowers the cleaning frequency, and helps maintain a lower pressure drop across the system. By easing the burden on the filters, you can run more airflow through the baghouse without overloading it, effectively gaining capacity without adding modules or replacing the unit.

💡#5 — Switch to Better Fabric Including PTFE Membrane

- Upgrading to high-performance filter fabrics, such as those with a PTFE membrane, can immediately increase a baghouse’s effective capacity without changing its size. PTFE membranes act as a surface filter, preventing dust particles from penetrating deep into the fabric and forming heavy dust cakes.

The microporous ePTFE structure shown here allows gases and vapors to pass while blocking liquids and particles.

- This keeps airflow moving freely through the bags, lowers pressure drop, and reduces the frequency of cleaning cycles. With less resistance in the system, the same collector can handle more airflow while maintaining proper air-to-cloth ratios. Additionally, these fabrics are more resistant to moisture, temperature, and chemical attack, which means longer bag life and fewer shutdowns.

Every plant faces different challenges when it comes to dust collection, and there’s no “standard” solution for increasing baghouse capacity. The good news is you don’t have to figure it out alone. Our team has helped countless facilities determine the most cost-effective and reliable upgrades. If you’re struggling with high differential pressure, short bag life, or insufficient airflow, reach out to us today. We’ll review your system, discuss your production goals, and recommend the best path forward to maximize your dust collector’s performance while keeping costs under control.

Most

Most