New bags take in, that’s why it’s essential to protect them during startup

Starting up a new set of filter bags in your baghouse might seem like a routine step, but it’s actually one of the most critical moments in determining how long those bags will last. Many operators don’t realize that what happens in the first 24 to 48 hours can make or break the long-term performance of the filters.

Here’s the issue: brand-new filter bags are clean and porous. That means air and dust can move through them very easily. If you send the full process flow through them right away, high-velocity dust particles can slam into the bare filter media, embedding deep into the fibers. This leads to premature blinding, where airflow is restricted, the pressure drop rises, and bag life is drastically shortened.

To understand this better, let’s talk numbers. A brand-new bag may have a permeability of 25 to 60 CFM/ft². That’s how easily air flows through it. A seasoned bag with a healthy dust cake may be down to 5 to 10 CFM/ft². A bag that’s blinded? Less than 2. That’s a massive drop. The takeaway: new bags take in a lot more air and dust—if you’re not careful. That’s why it’s essential to protect them during startup.

What’s The Right Way to Start Up a New Baghouse Compartment?

The short version: precoat, restrict, and go easy on the cleaning.

Precoat powder comes in 50-lb bags.

Start by applying a precoat—a compatible fine powder like limestone dust or commercial precoat products. This coats the clean bags with a thin layer of dust that acts like a buffer. It protects the fabric from direct contact with abrasive or sticky dust, and helps absorb moisture or acids that might form when the system is heating up.

Think of this step like preparing a fishing net: imagine you’re about to toss a net into a lake full of small fish. If you send it in empty, the fish will slip right through the holes. But if you first catch a few big fish and they block the holes, they form a barrier—so that even the smaller fish can’t pass through anymore. That’s exactly what a precoat does. The coarse particles land first, fill in the open pores of the fabric, and create a protective layer. When finer, stickier particles arrive later with the process dust, they’re less likely to get embedded in the media because the “big fish” have already blocked their path.

Next, limit the airflow. For reverse gas or shaker baghouses, you can do this by closing inlet or outlet dampers down to about 20% or by slowing down the fan. For pulse jet systems, you can also reduce fan speed or limit compressed air. Remember, the goal is to keep flow near the design air-to-cloth ratio, not wide open. Just enough to ventilate the system.

Finally, reduce or disable the cleaning cycle for the first 8 to 12 hours—or even longer if possible. That dust cake needs time to build. In reverse air systems, stop the reverse gas or shaking. In pulse jets, lower the compressed air pressure going to the pulse header. If you start blasting the bags too early, you’ll strip away the precoat and delay cake formation.

A Few Extra Tips

- 🔹 If your baghouse has hopper heaters, use them before startup to preheat the compartments. This helps you avoid hitting the dew point and forming condensation.

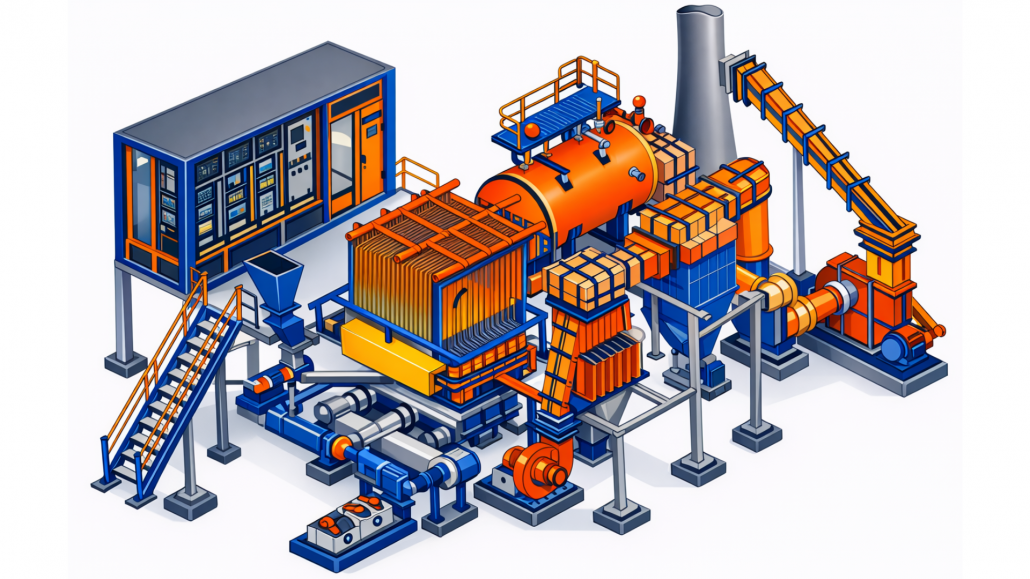

Turn on the hopper heaters before startup to preheat the compartments to avoid condensation

- 🔹 Be especially cautious with high-moisture or acidic processes—the precoat is even more important here.

- 🔹 Always document how the startup was handled. If you notice premature failures later on, it’s helpful to trace things back to how the bags were introduced into service.

The Payoff of a Proper Startup Routine

Taking care of your bags during startup is one of the smartest things you can do to extend their life and avoid expensive issues down the road. A little extra attention now can save you thousands of dollars in early bag replacements, lost production time, and increased energy costs.

Don’t let brand-new filters fail early. Precoat them, limit the airflow and give the filters time to settle in.