The process of selecting a baghouse filter supplier for your next set of replacement filters might seem like a simple task. You might think that all you need to do is call them up, tell them your model number and you will be set. But is it really that easy? Can you always rely on just any supplier to get you the right bags, at the best price, every time?

Outlined below are several things that will help you to find the right supplier for your next set of replacement baghouse filters. Going into the filter quoting process armed with this information will enable you to secure the products at a fair price. These are the three key points to keep in mind when searching for your next set of replacement bags.

Have The Correct Information Before You Call

Most people begin their search for replacement bags with only the most basic of information, if any at all. At times all they have is some supplier’s arbitrary product number from their last set of bags, or a serial number from the side of their baghouse. The fact is that there is no central database of baghouse filters out there for your supplier to check. The majority of these product numbers are from their respective manufacturers and only for their internal record keeping/branding.

In order to receive an accurate replacement baghouse filter RFQ more information will be needed. While you may not have easy access to all of this information when sourcing quotes, the more you have the easier it will be for the supplier to give you an accurate quote. Information to have on hand includes:

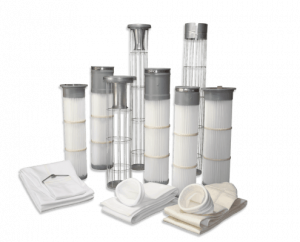

✅ Dust Collector Type – What kind of filters, cleaning system type, etc.

- ➡️ Shaker

- ➡️ Reverse-Air

- ➡️ Pulse-Jet

- ✔️ Bags

- ✔️ Pleated filters

- ✔️ Cartridges

- ✔️ Envelopes

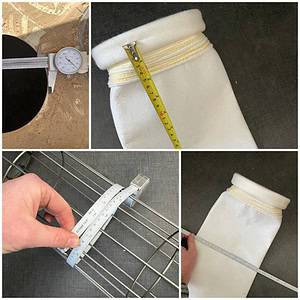

✅ Filter Measurements – Physical dimensions of the filters

- ➡️ Length

- ➡️ Diameter

- ➡️ Flat-Width

✅ Filter Construction – This differs based on how the bags are installed in the baghouse

✅ Filter Construction – This differs based on how the bags are installed in the baghouse

- ➡️ Top (Snapband, Strap, Raw Edge, etc.)

- ➡️ Bottom (Snapband, Disk, Compression, etc.)

✅ Filter Fabric – The material along with any coatings, finishes or membranes

- ➡️ Fabric (Polyester, PPS, Cotton, Fiberglass, etc.)

- ➡️ Coating/Finish (Singed, fire-resistant, etc.)

- ➡️ Membrane (PTFE, etc.)

✅ Special Considerations – Special added features needed only on certain bags

- ➡️ Antistatic wires

- ➡️ Support rings

It is also good to include a general overview of the process the filters are used for. This would include air temperature, product to be filtered, alkali or acidic level, combustibility of the dust, etc. You should also including information about how often you replace your filters, system pressure drop, filtering efficiency. While not absolutely necessary, this information will allow a good supplier to offer suggestions for different products that might improve the operation of your system.

Remember to have as much of this information on hand before you begin contacting filter suppliers. If you are not sure about some of these specifications try to get as much as information as possible and then a good filter supplier can help you to find the rest.

For help see article “How to Chose The Correct Baghouse Filter.”

How to Choose a Baghouse Filter Supplier

There are hundreds of filter suppliers, manufacturers, and sales reps out there to choose from. Finding one that will get you the best product and provide you with the best service for a fair price is no easy task.

Often times, companies portray themselves as “dust collection experts” when in reality they are only sales reps that have little real knowledge of how these complex industrial systems operate. You will want to consider their level of experience in the industry. Companies with real-world experience in the field are able to provide a vastly superior service than the rest. For example, an experienced supplier will be able to not only take your order, but also offer suggestions on how to improve your dust collector operation by offering tips on installation methods, maintenance procedures, and other ways to increase system efficiency, and extend bag life. They also will be able to offer suggestions for different products (such as new fabrics, pleated elements vs. traditional bags, etc.) that could reduce costs and increase efficiency.

Additionally, you should look into the reliability and trust-worthiness of the company before doing any business with them. This can include asking for references from their previous clients, reviewing their return policy, and any guarantees they may offer on their products.

Routine maintenance is critical to ensure your dust collection system operates efficiently.

Additionally, you may wish to seek out a supplier that also offers baghouse filter replacement services as well. Having qualified technicians install your new baghouse filters often is a better choice than using in-house personal. Many times filter suppliers will provide you with a far better price for your filters if you also use them for the service work.

The knowledge an experienced supplier can provide is invaluable. Take advantage of this by seeking out a trust-worthy, and experienced supplier.

Note: A good filter supplier should allow you to send in a sample of your current bags to ensure they are measured correctly. This can be an extra bag, or one from the baghouse (you can remove it and cap off the spot where it was to prevent leaks).

Do Not Forget About Filter Replacement Services!

While many facilities elect to install their replacement filters themselves, usually to keep costs down, it is not always the best idea to simply assume that using in-house labor is the best option. Many problems can result when workers without specific baghouse training attempt to carry out baghouse service work. This can include damaging the filter bags during installation (some bags such as those with PTFE membrane are somewhat fragile and require care when handling), improperly installing the bags (not sealing them correctly, improper tension, etc.) that can lead to leaks and early failure of the bags among other things. Additionally, workers may not have experienced dealing with baghouse-specific safety hazards and could injure themselves quite easily.

Furthermore, using in-house labor often takes much longer than using experienced baghouse technicians to install your replacement filters. These technicians are experienced in the design and operation of all different types of baghouses and know the best methods for replacing the filters safely in the shortest amount of time. Often when facilities choose to have in-house labor do the filter changeout it results in long delays that cost the plant much in terms of labor costs and facility down-time. Additionally, many times some of the filters are damaged or installed incorrectly and thus the plant will have to spend additional resources later on to track down the problem and correct it.

Example: One plant decided to have its normal maintenance workers change out all of its bags. 18 compartments, with 200 reverse-air, springs and chains. On average it took them 3 days to do one compartment. Often with mistakes (poorly sealed bags, not fitted in the snapband, wrong tension, etc.). Our crews did 4 a day, and scrapped the walls of rust scale and did leak testing.

Expert crews are trained to recognize problems, holes, warped metal, failing welds, rusting metals, moisture problems, abrasion, etc. Many filter suppliers also provide replacement services as well. While we will have an additional article on the topic of selecting a baghouse service provider, in short we can say that selecting a service provider may be even more important than choosing the filters themselves. A qualified and experienced service team will not only ensure that filters are installed correctly and safely, but will also verify that the system operates at peak efficiency after installation. This includes performing inspections, identifying potential issues such as leaks or improper bag fit, and running leak testing procedures to confirm optimal performance. Partnering with a trusted provider helps extend filter life, minimize unplanned downtime, and maintain compliance with emissions regulations.

Conclusion

Sourcing a quote for replacement baghouse filters is not a task to take lightly. The difference between a capable filter supplier and a poor one is dramatic. While it may not always be easy to find a good supplier, by following the suggestions in this article you can find one that can provide you with the products you need for a fair and reasonable price.