The rapid growth of the electric vehicle (EV) industry and energy storage solutions has brought lithium-ion battery manufacturing into the spotlight.

The rapid growth of the electric vehicle (EV) industry and energy storage solutions has brought lithium-ion battery manufacturing into the spotlight. As production scales up, managing hazardous dust and fumes generated during manufacturing is critical for safety, quality, and environmental compliance. This article explores the intricate process of designing effective dust collection systems tailored for battery manufacturing, emphasizing best practices, challenges, and innovations to ensure a safe, compliant, and high-quality operation.

How Lithium-Ion Batteries Are Made: Step by Step

Thanks to their high energy density, rechargeability, and long lifespan, lithium-ion batteries power everything from smartphones to electric vehicles (EVs). But how exactly are they made before they end up inside your EV?

Let’s walk through the main stages of lithium-ion battery production, from raw material extraction to final quality testing.

Step 1: Raw Material Extraction and Preparation

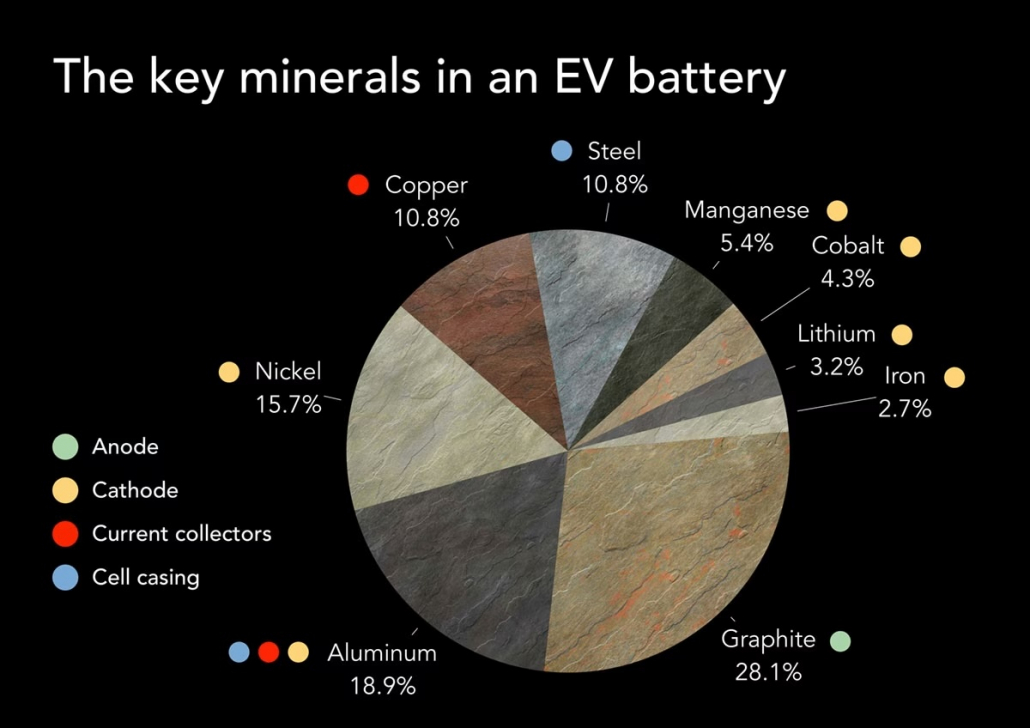

Critical materials for lithium-ion batteries include lithium, graphite, cobalt, and manganese.

Production begins with extracting key raw materials. According to the National Renewable Energy Laboratory, critical materials for lithium-ion batteries include lithium, graphite, cobalt, and manganese.

Inside the battery, these materials form the two main electrodes:

- ✅ Anode: typically made from carbon-based materials such as graphite.

- ✅ Cathode: composed of metal oxides containing lithium, cobalt, and manganese. These materials allow electric charge to flow between the electrodes during charging and discharging.

Step 2: Active Material Synthesis

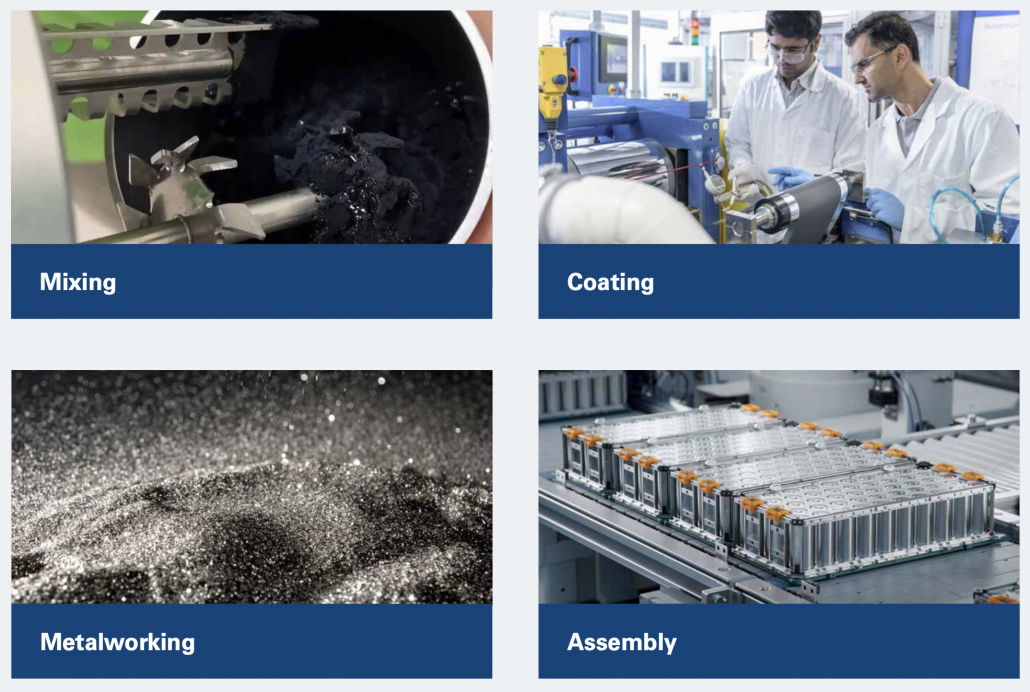

Next, the extracted raw materials are refined and synthesized into active electrode materials with precise chemical and physical properties. This process often involves mixing, heating, cooling, and combining base metals with lithium, graphite, and binders. The goal is to create uniform, high-performance compounds for the anode and cathode.

Step 3: Electrode Manufacturing

Dust in battery production tends to be dry, fine, and lightweight, often containing hazardous metals like cobalt, nickel, lithium compounds, and other reactive materials. Fumes can be flammable, needing strict fire safety measures. Areas such as slurry mixing, electrode coating, slitting, and cell assembly are hotspots for dust creation, with dust onset during material handling and processing steps. Both dust and fumes can contribute to combustible explosions and pose inhalation hazards, that’s why the need for specialized collection and filtration systems.

Step 4: Cell Assembly

Lithium-ion battery cells can take different forms: cylindrical, prismatic, or pouch cells. During assembly, anode and cathode sheets are stacked or wound together with a separator between them to prevent short circuits. Then, the cell is filled with electrolyte, which enables lithium ions to move between the electrodes. The cell is finally sealed to prevent leaks and contamination.

Step 5: Cell Formation and Aging

In this stage, cells undergo a series of controlled charging and discharging cycles. This activates the electrolyte and forms a solid electrolyte interphase (SEI) layer on the anode, which is essential for battery performance and durability. After formation, the cells are left to age and stabilize, ensuring consistent performance before further assembly.

Step 6: Module and Pack Assembly

Thanks to the high energy density of lithium-ion technology, manufacturers can design compact, powerful battery systems for a wide range of applications.

Individual cells are grouped into modules, and multiple modules form a battery pack. Each pack is equipped with a Battery Management System (BMS) that monitors voltage, temperature, and performance to maintain safety and efficiency. Thanks to the high energy density of lithium-ion technology, manufacturers can design compact, powerful battery systems for a wide range of applications.

Step 7: Quality Control and Testing

Finally, every lithium-ion battery goes through strict quality control and safety testing at multiple stages. This includes: Material inspections, in-line production checks, performance and capacity testing and electrical and safety evaluations.

These steps ensure each battery meets exact performance and safety standards before reaching the market.

Dust Collection System Design Principles for Battery Manufacturing

Effective dust collection hinges on a combination of properly designed hoods, ducts, fans, and filters:

- ✔️ Hood Design: Capture hoods must be positioned close to emission points and designed to optimize airflow velocities (usually 150-200 ft/min for dust and fumes), minimizing both overshoot and energy consumption.

- ✔️ Ducting Infrastructure: Size and slope ducts correctly to maintain minimum conveying velocities (commonly 4,000-4,500 ft/min for combustible dust) to prevent settling and blockages, avoiding turbulence and wear.

- ✔️ Fans and Ventilation: Size fans based on total static pressure, including filters, ductwork, and hoods, ensuring reliable operation and energy efficiency.

- ✔️ Filters and Dust Collectors: Cartridge collectors, especially models with nanoparticle filtration media, are ideal for capturing fine, dry dust without compromising airflow or adding excessive maintenance

Fire and Explosion Safety

Due to the combustible nature of many battery dusts, mitigation strategies such as system isolation (both mechanical and explosion venting), use of flame retardant filters, and chemical suppression systems are crucial. Conducting dust hazard analysis (DHA) determines fire/explosion risks and guides protective measures. The NFPA 660 standard provides guidance, but specific standards for battery manufacturing are evolving.

Preventive Maintenance and Monitoring

Modern systems incorporate electronic monitoring with smart sensors for filter differential pressure, fan operation, and alarm notifications. Bag-in, bag-out handling protocols prevent worker exposure to hazardous dust, and routine inspections help identify filter blockages or wear early.

Learning and Implementation Recommendations:

- ✔️ Engage with experienced dust collection providers early in facility design.

- ✔️ Conduct comprehensive dust hazard analyses to understand explosion and fire risks.

- ✔️ Implement smart monitoring and preventive maintenance routines.

- ✔️ Design for future scalability to adapt to technological changes.

- ✔️ Prioritize worker safety through proper PPE, bag-in, bag-out protocols, and training. With these strategies, manufacturers can ensure a safer, cleaner, and more efficient production environment—driving the future of energy storage and electric mobility.

As explained, battery manufacturing involves multiple intricate steps, all processes which inherently generate fine dust and fumes. These airborne particulates, often combustible and hazardous, pose risks of explosions, fires, and long-term health effects for workers.

Companies like Baghouse.com bring decades of expertise in customizing solutions to meet these unique challenges, all with an emphasis on safety, regulatory compliance, and operational excellence. As battery manufacturing evolves, continuous innovation and adherence to best practices will be vital in safeguarding facilities and advancing sustainable energy solutions globally.