— What exactly does a baghouse do in a cement plant?

Think of the baghouse as the plant’s air filter. It captures fine cement dust from grinding, mixing, and kiln operations before that dust escapes into the atmosphere. Dirty air enters through ductwork, passes through hundreds of fabric filter bags, and exits clean. The dust stays on the surface of the bags until it’s shaken or blown off during the cleaning cycle.

— What types of dust are collected in cement production?

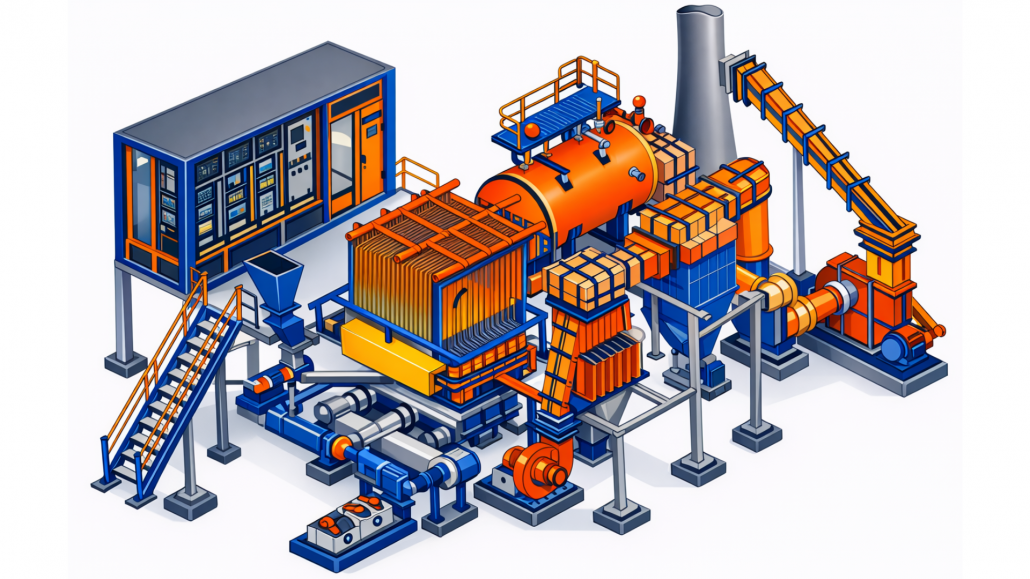

Chemical lime plant dust collection system

Every step of cement manufacturing creates different dust. Handling raw materials like limestone and shale produces coarse particles. Grinding and kiln operations generate much finer dust, sometimes small enough to stay suspended in the air for hours. Then there’s the abrasive mix dust from silos, which needs filters tough enough to resist corrosion and wear. That’s why choosing the right filter media for each stage is key.

— How can I prevent the hopper from clogging when humidity is high?

Dust collector hopper

When humidity rises, dust becomes sticky and bridges over the hopper instead of falling through. A few proven tactics include keeping hopper heaters or insulation active during humid conditions, ensuring your discharge system (like rotary valves or screw conveyors) stays dry, and never letting dust sit idle for long periods. Continuous dust discharge is the best prevention.

— My filter bags keep clogging when humidity increases — what can I do?

Humidity in the incoming air causes condensation and blinds the filter bags. The flue gas temperature should be above the dew point before entering the baghouse.

If your bags are blinding due to moisture, start by checking your cleaning system. Pulse valves or compressed air lines that aren’t firing properly can make it worse. Also, look for air leaks that might be pulling in humid ambient air. In some cases, switching to a bag fabric with a moisture-resistant or PTFE membrane finish can dramatically reduce buildup. And if the problem happens during startup, preheat the baghouse to reduce condensation.

— What should I do if I have torn bags but can’t shut down the baghouse?

This is a common challenge in cement plants that run continuously. If shutdown isn’t possible until an overhaul, isolate the compartment where the damage occurred if your system allows it. You can also temporarily plug the tube sheet opening to reduce bypass air. But these are only stopgaps — schedule a full changeout as soon as possible, because running with torn bags not only reduces efficiency but can also damage the fan and downstream equipment.

— How do I deal with corrosion inside the baghouse?

— How often should I perform maintenance on a cement baghouse?

— How do I know if my baghouse is performing well?

Your best indicator is differential pressure. A stable reading within the manufacturer’s range means airflow and cleaning are balanced. Usually, the normal range is between 3″ to 5″ of differential pressure. If pressure rises steadily, you’re likely dealing with bag blinding, moisture buildup, or a faulty pulse valve. If pressure drops too low, check for leaks or broken bags. Also, keep an eye on visible emissions; a sudden increase in dust escaping the stack is a sure sign something’s wrong.

— What should I include in a baghouse inspection checklist?

A solid inspection form should cover a few essentials:

- ✅ General info: date, location, production rate, and environmental conditions during inspection.

- ✅ Visual condition: look for damaged bags, dust buildup, rust, or cracks in the housing.

- ✅ Operational data: record differential pressure and compressed air pressure.

- ✅ Observations: note any weak pulse, uneven cleaning, or abnormal sounds from valves or blow pipes.

Keeping consistent records helps you track performance trends and catch issues early.

— What’s new in cement baghouse design?

Modern cement baghouses have evolved. Some systems now feature round bag designs that clean themselves automatically, reducing the need for shutdown maintenance.

IoT sensors are also revolutionizing how maintenance is performed in cement plants. Predictive maintenance (enabled by real-time data from connected sensors) means you can fix stuff before it breaks. This transition not only saves money on repairs and energy but also increases equipment lifespan and improves overall plant efficiency.

Read more about this in the article: Smarter Cement Plants: The IoT Revolution You Can’t Ignore

— Is silicosis a risk in cement manufacturing? What protection should workers use?

Silicosis risk depends on whether your raw materials contain free silica. But even if they don’t, workers should always avoid breathing dust. Proper dust masks or respirators must be worn in dusty areas. The finished cement product itself doesn’t contain free silica.

Read more in the article: Hazardous Dust: Key Risks and Practical Management Solutions

— Our electrostatic precipitator (ESP) on the long dry kiln (2520 TPD) is not working. A company suggested replacing it with a water fogging system that sprays 10-micron droplets into the kiln riser pipe. They claim it can capture up to 80% of the dust before the ID fan. Do you think this is a good idea? What are the pros and cons?

We don’t see many advantages to this idea. Normally, water spray is used in a conditioning tower to cool and humidify gases before they enter the ESP. In that setup, up to 80% of the dust might fall out in the tower.

However, spraying directly into the kiln riser is very different, it’s not an expansion chamber. Cooling the gases there would also make them contract, increasing the draft at the kiln inlet and possibly causing more dust to escape from the kiln. I don’t recommend this modification. A deeper analysis of the problem is needed before making any changes.

— We produce white cement and are having problems with lumps forming and coating on the silo walls. The cement enters the silo at about 80°C, and we run a bag filter continuously to remove moisture. How can we stop this problem? Would using a polymer liner or insulating paint inside the silo help?

At 80°C, the cement is still hot enough for gypsum dehydration to continue, which causes lumps and buildup. You should cool the cement below 70°C before it enters the silo.

Another solution is to raise the cement mill outlet temperature to around 115°C so gypsum dehydration finishes inside the mill instead of the silo.

— How do I choose the right silo bin vent?

If you know your silo’s capacity, that’s often enough to recommend one of our standard bin vents. However, for a more accurate selection, it helps to provide a few key details stated in the following question.

— What information do I need to provide when selecting a silo bin vent?

The more specific your data, the better we can match a collector for your needs. Here’s what helps most:

- ✔️ Material stored in the silo: Cement, sand, gravel, or other bulk materials. Each has different dust characteristics.

- ✔️ Required airflow capacity: This depends on your pneumatic pump’s output and how often you load the silo.

- ✔️ Loading frequency: For example, twice per week or twice per day. This affects both the cleaning method and the filter’s air-to-cloth ratio, more frequent loading requires more filter area.

- ✔️ Loading pipe size: Ensures the airflow matches the system’s capacity.

- ✔️ Pressure relief valve: In some cases, you may need an emergency valve to prevent overpressure if the filter becomes blocked.

If you don’t have all this data, that’s fine, we can estimate using a safety margin of 1.2–1.5× to make sure the bin vent performs reliably under all conditions.

— What’s better: a cartridge filter or a baghouse filter?

Cartridge filters are less expensive upfront and suitable for smaller silos or less frequent loading.

This depends on your operation’s workload and budget priorities.

- ✅ Cartridge filters are less expensive upfront and suitable for smaller collectors or less frequent loading.

- ✅ Baghouse filters cost more initially but are designed for heavier use. They handle frequent loading and higher dust volumes much better.

In other words, if your collector has regular or high-volume use, a baghouse filter will save you more money in the long run by reducing maintenance and filter replacements.

— Which Filtration Media Is Best for Cement Dust Control?

The first step in deciding which filtration media to use is knowing what is trying to be captured.

General applications for Aramid felt includes highly abrasive dust and chemical applications with high temperatures

If the application involves fine dust particles in high concentrations, then it would be best to use synthetic fiber filters. Highly concentrated dust particles need a greater surface area for adsorption/collection of smaller-sized particles. Two highly reliable filtration media for concrete dust collection are aramids and Polyester.

Aramids, also known as Nomex, is cost-effective and highly efficient at filtering small particles at high temperatures. Nomex can successfully filter particles down to the 2 micron range. Felted aramids are generally the first choice for pulse jet baghouses used in cement, utility and incineration operations around the world. If a project needs to be able to filter even smaller particles, Baghouse.com offers a Nomex product with the ability to filter particles down to the submicron range.

Polyester baghouse filter

Polyester is another popular filter media used in concrete plants. Polyester can be clad with a PTFE treatment to maximize its chemical resistance.

How can I train the maintenance personnel at my cement plant?

At Baghouse.com, we offer several flexible training options tailored to cement plants and other heavy-duty operations:

▶️ In-person training: Hands-on, on-site instruction focused on your specific system and challenges. This option includes a system audit with a report on possible improvements to your facility.

▶️ Virtual training: Live sessions led by our experts, ideal for teams at multiple locations.

▶️ Online training course: Self-paced modules covering everything from filter changeouts to differential pressure analysis.

▶️ Combined training: A hybrid approach that blends virtual lessons with an expert, along with the Online training course.

Do you have any additional questions that were not covered in this article?

If you have specific questions about your cement baghouse setup or want expert guidance on maintenance or upgrades, reach out to the team at Baghouse.com. Our dust collection specialists can help you evaluate your system and offer practical solutions tailored to your operation.