The right accessories and replacement parts for your baghouse make all the difference. Pulse valves, solenoids, filter bags, cages, and control boards, every component plays a key role in maintaining consistent airflow and proper cleaning cycles. In this article, we’ll look at the most important baghouse accessories, what they do, and how they help extend the life of your system while reducing maintenance downtime.

What Do Controllers and Timers Do?

Baghouse filters are cleaned when compressed air is blown into the filters to release dust buildup. A pulse controller times the burst of compressed air that is used to clean baghouse filters, a practice that improves baghouse efficiency and increases bag life.

Types of pulse controllers

Pulse controllers come in two types, a simple timer and an on-demand timer.

.

• ✅ On-demand timer: For this pulse controller, the timer reads the differential pressure across the baghouse and initiates a pulse sequence once the differential pressure reaches a high set point. It continues to pulse until the pressure across the baghouse reaches the low set point. Once at the low set point, pulsing stops until the differential pressure reaches the high set point again. Because filters are cleaned only when needed, the advantages of an on-demand pulse controller include extended bag life and reduced compressed air consumption.

Set up parameters for pulse controllers

Several parameters can be set on pulse controllers. The simple timer has just two:

• ✔️ Time the valve is open: This time correlates to how much compressed air is released through the valve. A quick pulse of air, for example, is just 0.05 of a second.

• ✔️ Time the valve is closed: This is the amount of time between pulses. It can typically be set to anywhere from one second to several hundred seconds.

Besides the high and low pressure parameters listed above, the on-demand timer also includes the following:

• ✔️ Alarm pressure: Alarms can be set to notify the operator of issues with the bags. A high-pressure alarm indicates a plugged bag. For example, a high-pressure set point may be six, and an alarm may be set for nine or ten. Conversely, a low-pressure alarm indicates a bag needs replacement because of a leak or detachment.

• ✔️ Pulse sequencing: Operators can set the order in which the valves release air.

As an added note, when installing a pulse controller, avoid locations exposed to direct sunlight or areas near heat sources or electromagnetic fields, as these can damage the controller.

Troubleshooting your pulsing system

If you experience issues with the pulse controller, there are several things you can check depending on the problem:

• ✔️ Valves are not pulsing: Check the power to the timer, the differential pressure switch, header pressure, and the solenoid and/or diaphragm valve.

• ✔️ Hissing sound from valves: This may indicate a possible compressed air leak.

• ✔️ If the solenoid air outlet is leaking, check:

• ➡️ The electrical connection

• ➡️ The sub-assembly for debris

• ✔️ If the diaphragm valve outlet port is leaking, check:

• 🔵 The air line to the solenoid

• 🔵 Header pressure

• 🔵 The inside valve body for pitting and debris

• 🔵 The membrane for wear

• ✔️ Bags are not cleaning adequately: Check the pulse pressure, on-time and off-time, and pressure set points. It may also indicate the need for a bag change.

We also recommend that you keep an adequate supply of dust collector filters and pulse valve kits on hand to avoid costly delays in production.

Clean-On-Demand Baghouse Control Systems

Baghouse.com offers a full line of baghouse control systems designed to achieve maximum ventilation and collection efficiency. Clean-On-Demand controls monitor the differential pressure across the filter bags. The user sets the high and low differential pressure set points (generally ½” w.c. (12.7mm w.c.) apart), at which cleaning will start and stop. By operating the baghouse at a stable and optimum differential pressure, you avoid both over-cleaning and under-cleaning the filter bags.

Benefits of Clean-On-Demand Controls

• 🔵 Maintains optimum dustcake for filtration efficiency

• 🔵 Helps protect bag fabric from blinding and bleed-through for better airflow and lower emissions

• 🔵 Reduces flex cycles on filter bags, increasing their lifespan

• 🔵 Maintains stable ventilation with no over- or under-ventilation issues

• 🔵 Helps lower compressed air consumption and operating costs

Standard Clean-On-Demand Controller

• 🔵 Solid-state construction

• 🔵 Digital input for pulse time, pulse duration, and number of valves

• 🔵 Low-profile photohelic gauge with high and low differential pressure set points

• 🔵 Enclosure

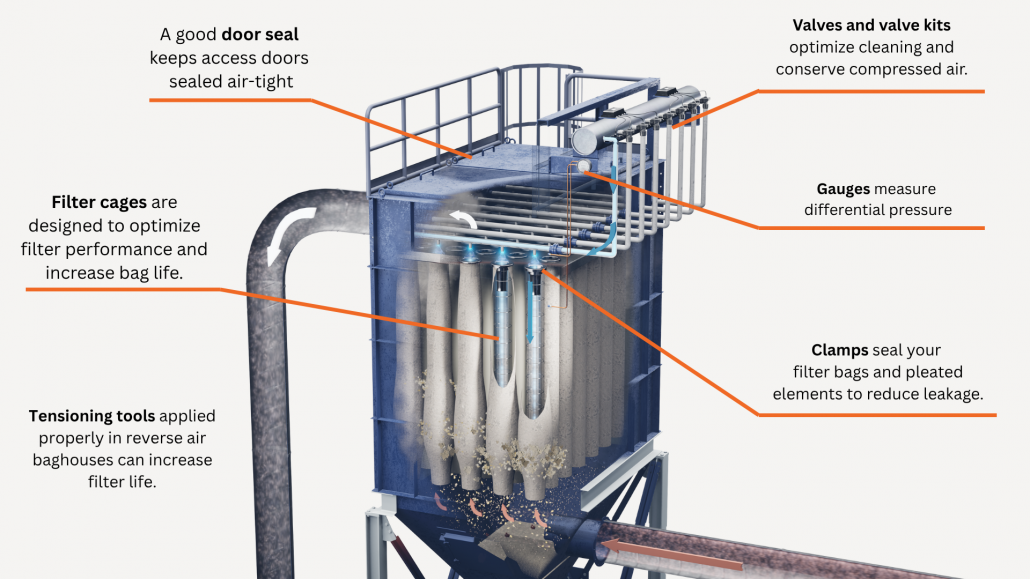

Why Are Good Cages Important?

Filter cages might seem like simple components, but they are quite essential. When filter bags don’t fit snugly onto the cages, or when cages are not replaced when needed, system performance can suffer significantly. Neglected filter bag cages are often the root cause of many operational problems in industrial environments.

A key feature is the precise fit between the filter bag and the cage, ensuring proper adhesion and long service life. Quality filter cages are built to withstand cleaning cycles, bag changes, abrasive materials, high temperatures, and other demanding environmental conditions.

Cages should also withstand the pressure exerted by the filter bag during particulate collection and provide uniform support along the entire length of the filter cloth.

Regardless of design, each cage must consistently meet specifications, including correct diameter, total length, and other tolerances. The technologies we use at Baghouse.com ensure your cages are built to spec, providing a precise fit between the filter bag and cage, which results in optimal cleaning performance.

Our dust collector cages can be made to fit existing collectors from any manufacturer, including Astek, Gencor, Flexkleen, Mikropul, and Wheelabrator. We can also manufacture uncommon and specialized cage designs as needed.

Clamps – How Do They Keep Your System Leak-Free?

When you buy new filters, it’s important to buy new clamps as well. Clamps are designed to protect your filter bags and simplify installation. Our clamps extend bag life by reducing leakage and abrasion. We offer a variety of designs and sizes engineered to meet your specific needs. They can be used with raw edge, cord, hem, or sleeve-constructed bags, and some pleated filter elements.

There are several reasons why clamps can fail:

• ❌ Misapplication

• ❌ Misplacement

• ❌ Over-torquing

• ❌ Reuse of old clamps

• ❌ Corrosion

Our dust collector experts recommend replacing clamps each time you change your filters.

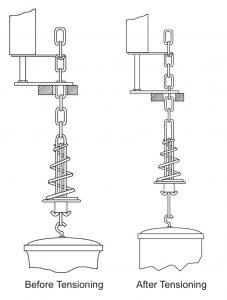

Tensioning Tools – Why Are They Key for a Secure Filter Fit?

We have developed a variety of tensioning assemblies to best fit your application. The assemblies are available in chrome silicon steel for moderately elevated temperatures or 17-7 PH stainless steel for high-temperature applications.

Conical Spring

Unlike a linear spring (which compresses equal amounts for equal pounds of load applied) a conical spring becomes harder to compress as heavier loads are applied. It acts as a shock absorber, preventing the fabric from collapsing completely during the reverse air cycle, and reduces the “popping” effect on the bags when returning to service. This spring is used in the I-Bolt and Double Draw Bar Assembly and the Pre-Loaded Rod and Draw Bar Assembly.

I-Bolt and Double Draw Bar Assembly Features and Benefits

• ✅ Hitch-pin design allows easy maintenance when re-tensioning

• ✅ Simple adjustment and installation reduce labor costs

• ✅ Provides proper tensioning for optimal collection efficiency

• ✅ Prevents bag-to-bag abrasion

• ✅ Patented cup washer centers the spring on the bolt, resisting buckling and abrasion

• ✅ Non-linear compressibility supports both bag and dustcake

• ✅ Provides required pre-load and travel for correct tensioning

The Pneu-Magnum AC Tool

The Pneu-Magnum AC Tool is a pneumatic tensioning tool designed to simplify and standardize the process of tensioning filter bags in reverse-air baghouse systems. It uses compressed air to lift and apply precise tension to the filter bag assembly, ensuring that each bag is tightened evenly and to the correct specification.

This tool operates on a 3:1 pressure principle, meaning that for every 1 psi of air pressure applied, the tool produces approximately 3 pounds of lifting or bag tension force. This allows operators to easily set the desired tension level by simply adjusting the air regulator knob—eliminating the need for manual guesswork or inconsistent tightening with hand tools.

The Pneu-Magnum AC Tool makes filter bag tensioning easier because it:

✔️ Provides accurate and repeatable tensioning for consistent bag performance across the entire baghouse.

✔️ Reduces manual labor by using pneumatic power to compress the spring and lift the bag, instead of requiring physical effort.

✔️ Includes a built-in pressure gauge and regulator for precise control of the applied tension.

✔️ Improves safety, since operators can tension bags without having to reach or strain around the assembly.

✔️ Helps extend filter bag life by preventing issues like over-tensioning (which can damage fabric) or under-tensioning (which can cause bag flex and abrasion).

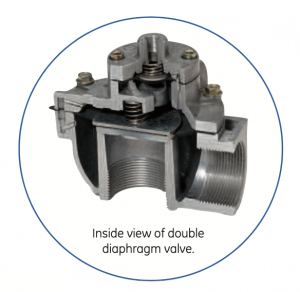

Valves and Valve Kits – What Role Do They Play in Cleaning Efficiency?

We supply a wide variety of valves designed to accurately fit your application:

• 🟠 Valves can be coated for extremely corrosive environments

• 🟠 Integral solenoid valves are mounted directly on the diaphragm valve

• 🟠 Remote solenoids are mounted in a separate enclosure

• 🟠 Valves available for high-volume / low-pressure applications

Door Seals and Access Doors – How Do They Protect Against Air Leaks and Pressure Loss?

• ❌ Corrosion of doors and walls

• ❌ Fugitive emissions

• ❌ Production losses

• ❌ Maintenance problems

• ❌ Reduced airflow due to condensation and filter blinding

Helpful Maintenance Tips

• ✅ Replace old door seals regularly

• ✅ Ensure the door is not warped and seals tightly

• ✅ Avoid frequent opening of access doors, which can disturb the seal

Baghouse.com Has the Perfect Access Door for Your Dust Collector

Need custom-made doors for your baghouse, ESP, or SCR system? Baghouse.com supplies access doors to fit all OEM applications, whether you need a stamped, round precipitator door with a key interlock, an insulated center-pivot baghouse door, or a large rectangular moisture-proof scrubber or SCR access door. All our doors are custom-manufactured for your needs. Many are preassembled and stocked, while less common styles are assembled and welded using precision jigs to ensure a perfect fit.

Gauges – How Can They Help You Track System Performance?

Keep Differential Pressure in Check with Pressure-Measurement Gauges

High differential pressure can damage filter bags, reduce airflow, and increase operating costs. Monitoring differential pressure with reliable gauges can also enable clean-on-demand functionality.

Magnehelic Gauge

A pressure gauge (can be magnehelic or photohelic) measures the differential pressure

The magnehelic gauge measures differential pressure between the clean and dirty sides of the baghouse, indicating the bag’s resistance to airflow. A sudden pressure drop suggests a leak, while a sharp rise indicates filter blinding or excessive dust cake buildup. This gauge provides critical data for troubleshooting and assessing operating conditions.

Photohelic Gauge

A photohelic gauge adds automation to the magnehelic’s measurement function. It allows operators to set high and low pressure points that automatically start and stop the pulse cleaning system as needed, maintaining stable performance and bag life.

Surge Valve

The Surge Valve provides fast, easy cleanout of gauge lines without manual disconnection.

Benefits include:

• 🔵 Simple push-button operation for quick line cleaning

• 🔵 Optional timer-controlled automatic cleaning

• 🔵 Temperature range 32°F (0°C) to 200°F (93°C)

• 🔵 Heavy-duty design rated for up to 150 psi (10.34 bar)

Auto Purge Valves

Automatic purge valves prevent moisture buildup in the compressed air header of pulse-jet systems. Without them, water from compressed air can cause corrosion, agglomeration, and hard-to-clean dust cake. The valve is installed at the bottom of the air header assembly and opens briefly during each pulse to discharge moisture, keeping your system dry and efficient.

Baghouse accessories play a critical role in maintaining efficiency, extending filter life, and ensuring reliable operation across all types of dust collection systems. Whether you need replacement parts, technical guidance, or complete accessory kits, Baghouse.com can help you find exactly what you need.

If you need assistance selecting or requesting baghouse accessories, our team is ready to help… just reach out to us, and we’ll make sure you get the right components for your system.