From Manual DP Checks to Continuous Monitoring – A Practical Guide

This article provides a simple use-case for the DustIQ predictive maintenance platform, describing how implementing a few sensors to replace manual differential pressure gauges can yield significant savings in man-hours, compliance risk, and up-time for your dust collection system.

There are many such use cases that can be addressed with the same DustIQ platform by simply adding more sensors. The objective here is to highlight the ease of installation and startup, and the rapid ROI for implementing these tools.

Background

Smart plant, digital transformation, IoT… these terms have been used for years to describe a future state of industry where manual inspections, processes, and routine tasks are replaced by connected sensors feeding data from across the facility into a single system that streamlines operations. Everything from tracking inventory to regulating building temperature to predicting equipment failures would ideally be managed through software, reducing labor hours, process interruptions, and compliance issues. As Eric Schummer, CEO of Senzary, often says, “The goal was never just to connect machines, it was to make the data actually useful for the people running the plant.”

In practice, many early technologies struggled to deliver on that promise. Integrating them with legacy IT systems was difficult, departments often lacked alignment, and objectives weren’t always clearly defined. This led to a patchwork of systems and sensors that sometimes created more work instead of less. Operators frequently found that data was trapped behind licensing walls, dashboards were hard to navigate, and installation or configuration required expensive engineering support. As Schummer puts it, “Companies didn’t fail at IoT — IoT failed them, mostly because it wasn’t built with the end user in mind.”

Opportunity

In recent years with the advent of AI-supported software and machine learning algorithms, lower cost and higher power sensors, and focused effort by a handful of providers to address these issues, the dream of the “Smart Plant” is actually quite accessible for most facilities.

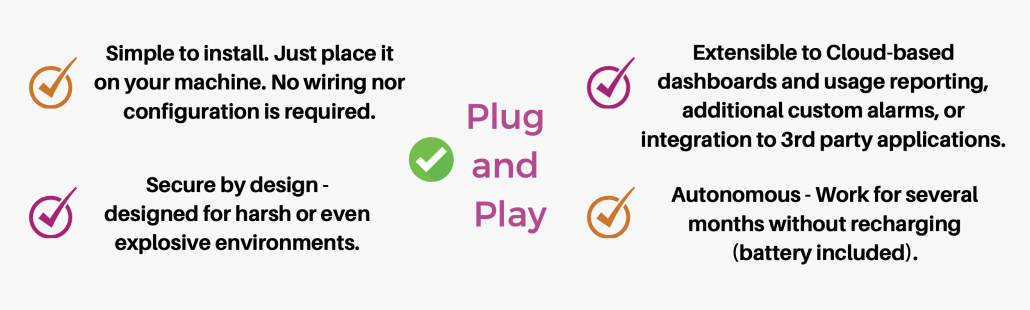

Senzary’s DustIQ platform is one such success story. With DustIQ in place as a backbone providing user-friendly dashboards, reporting, and alerts, the user simply needs to add sensors. Senzary offers a huge range of compatible wireless sensors, which transmit data wirelessly via LoRaWAN gateways at the site. Available sensors include fan vibration, environmental monitoring (temperature, humidity, gas and particulate monitoring), air and water flow, room occupancy, and the list goes on. As a single LoRaWAN gateway can serve dozens or hundreds of sensors within a few hundred meter radius, the system can be quickly and cheaply scaled to add processes and sensors to the system once in place.

time monitoring of dust levels and

filter performance

Replacing Manual DP Checks

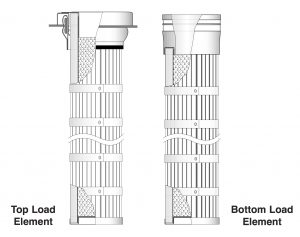

Now to our particular use case. Virtually every air quality permit for a dust collection system in the US requires the site owner to monitor differential pressure across the dust collector filters and take action when the DP exceeds the set limits. Typically this is done with a simple Magnahelic-style analog gauge. To stay compliant, many facilities still send someone out every day to manually check and record the DP on each dust collector. As Matt Coughlin, Owner of Baghouse.com, puts it, “It still amazes me how many plants rely on someone climbing a ladder with a clipboard to check something we can monitor automatically every second.”

Even with photohelic or transmitting DP gauges, where a 4-20mA signal is sent to a control room, the information often ends up buried in spreadsheets or forgotten reports that someone has to manually retrieve to meet compliance requirements.

Benefits

-

✔️ Labor hours reduced

- 🔵 For a site with 4 dust collectors, an average of 20 hours/month will be saved in manual inspections.

-

✔️ Reduced shut-downs due to broken/plugged filters

- 🔵 By tracking DP across time, site maintenance will know well in advance with a filter change will be required, so filter changeouts can be planned around production instead of reactively.

-

✔️ Safety improvement

- 🔵 There is no longer any need for operators to climb ladders in bad weather, ice, etc. to manually check and record DP

-

✔️ Better record-keeping

- 🔵 The data is logged in the DustIQ dashboard for easy retrieval

-

✔️ Real-time data and continuous monitoring

- 🔵 Instead of one data point per day, which may vary based on the filter cleaning status, data can be logged up to every second, for better data integrity

-

✔️ Rapid Deployment

- 🔵 Unlike legacy “IoT” systems that required months of configuring and integration, the DustIQ platform can be deployed almost immediately with the cloud-based dashboard. Integration with existing SCADA or control systems can be added and expanded if desired by the customer.

Costs

The cost for implementing the DustIQ platform will typically be less than $25,000 to include hardware (sensors and gateway), software (DustIQ platform), and installation. This would include 10 or so sensors, so the price may be less for a smaller site with fewer sensors.

Sensors can be added for a few hundred dollars each. A single gateway is typically sufficient for an entire building or site.

Additional Opportunities

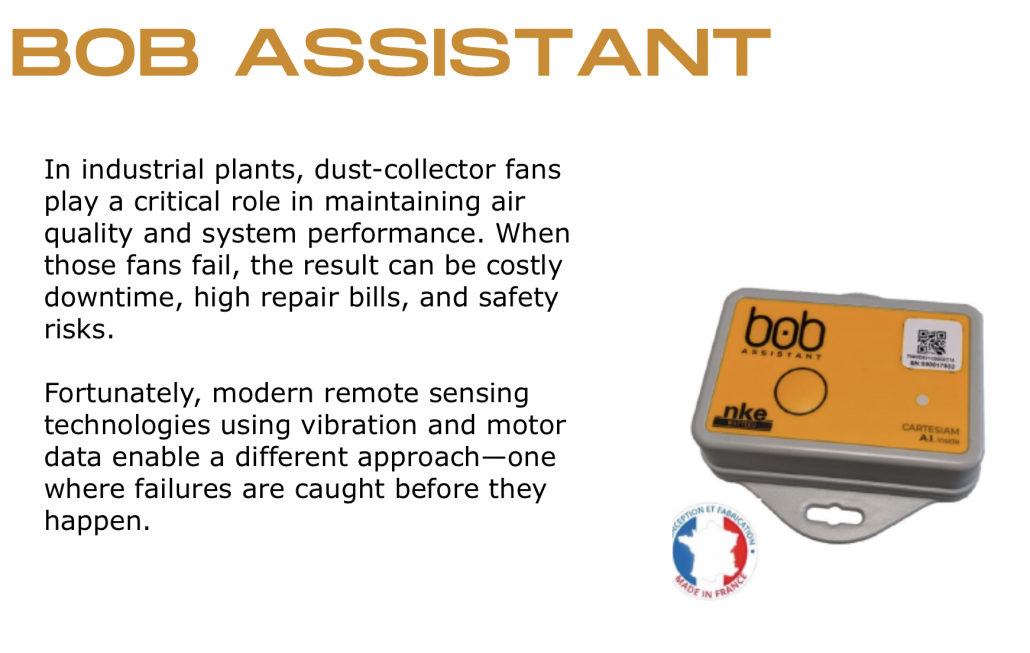

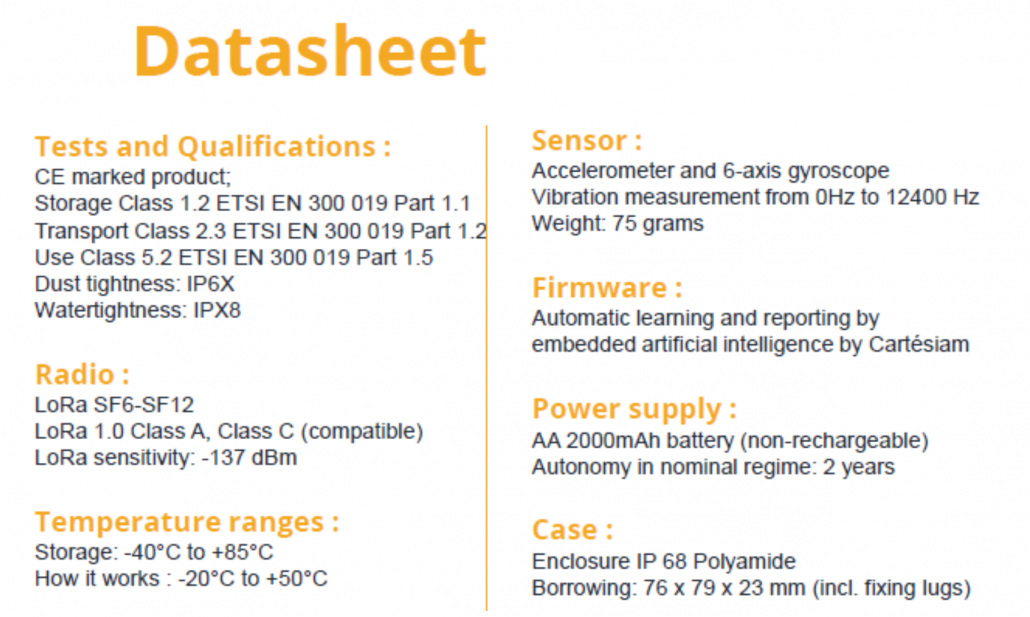

Once the DustIQ predictive maintenance operating system is in place, additional sensors can be added with very little effort. For instance, installing an NKE Watteco BoB sensor on fans and motors allows continuous vibration tracking, giving early insight into bearing wear or developing motor problems long before a breakdown occurs. Alerts and reminders work the same way they do with DP monitoring, keeping maintenance teams ahead of issues instead of scrambling after the fact.

Particulate sensors can be mounted on dust collector exhaust stacks to monitor emissions in real time, helping facilities catch broken or leaking filters before they trigger a compliance violation. Airflow and velocity sensors can measure dust and air movement through ductwork, making it possible to detect early signs of blockages. Indoor environmental sensors can monitor temperature, humidity, pressure, noise, and airborne particulate levels, offering better visibility into workplace conditions that fall under PM2.5 or safety requirements.

Eric Schummer, CEO of Senzary, often explains the value of this modular approach: “Once the platform is running, adding sensors is almost plug-and-play. You don’t need a big IT project every time you want more visibility. You just add a sensor and the system takes it from there.”

With this flexibility, it becomes easy to see how one platform can unify an entire facility into a practical version of a Smart Plant, cutting manual labor, preventing unplanned shutdowns, and reducing compliance risks across the board.

To learn more about how the DustIQ predictive maintenance operating system can be deployed at your facility, contact us now!

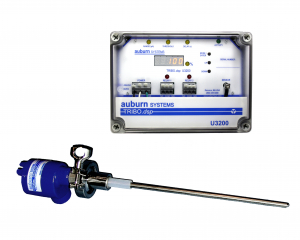

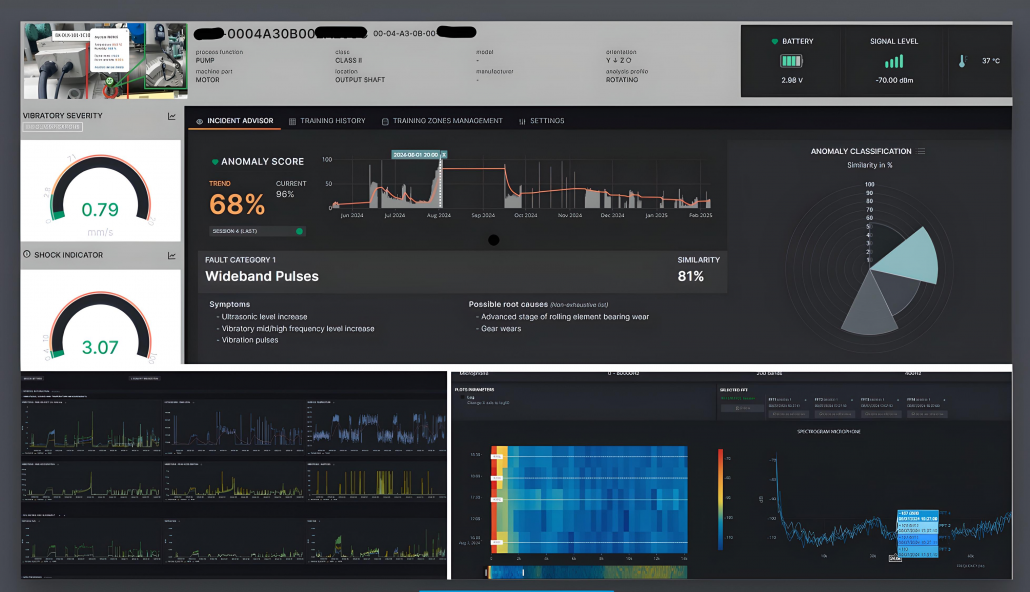

Remote IoT sensors attached to fan motors and rotating equipment continuously monitor parameters like vibration, acceleration, and temperature. Instead of periodic manual inspections, these sensors stream real-time data to a cloud platform. There, embedded analytics examine baseline behavior and flag subtle deviations, like early signs of misalignment, bearing wear, or imbalance. Once thresholds are crossed, the system sends an alert, giving maintenance teams time to intervene before a failure evolves. This predictive maintenance approach can dramatically reduce unplanned outages and extend the useful life of critical equipment.

Remote IoT sensors attached to fan motors and rotating equipment continuously monitor parameters like vibration, acceleration, and temperature. Instead of periodic manual inspections, these sensors stream real-time data to a cloud platform. There, embedded analytics examine baseline behavior and flag subtle deviations, like early signs of misalignment, bearing wear, or imbalance. Once thresholds are crossed, the system sends an alert, giving maintenance teams time to intervene before a failure evolves. This predictive maintenance approach can dramatically reduce unplanned outages and extend the useful life of critical equipment. An example of this technology is an IoT sensor package that mounts easily onto a motor or fan housing using magnets… no cabling, no shutdown required. The sensor uses a tri-axis accelerometer to track vibration patterns, and an embedded temperature sensor monitors heat build-up. After a short learning period, the device recognizes the normal operating “signature” of the equipment. From that point onward, any abnormal vibration or temperature anomaly triggers a predictive alert.

An example of this technology is an IoT sensor package that mounts easily onto a motor or fan housing using magnets… no cabling, no shutdown required. The sensor uses a tri-axis accelerometer to track vibration patterns, and an embedded temperature sensor monitors heat build-up. After a short learning period, the device recognizes the normal operating “signature” of the equipment. From that point onward, any abnormal vibration or temperature anomaly triggers a predictive alert.

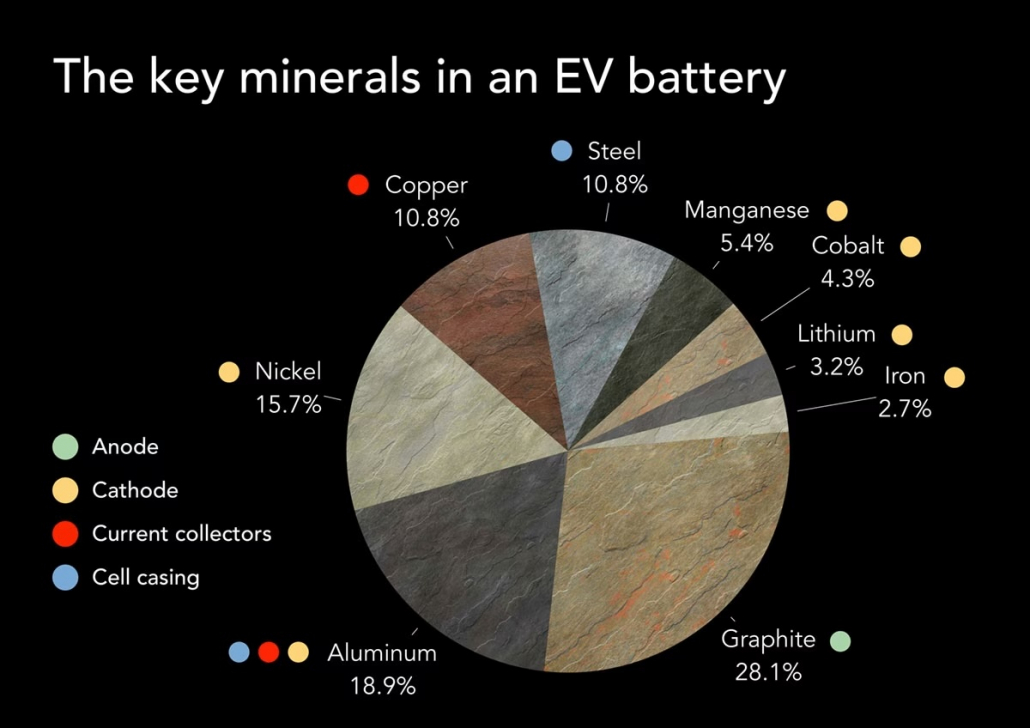

The electrode manufacturing stage includes three main steps: slurry preparation, coating and drying, and calendering. During slurry preparation, active materials are mixed with a solvent and binder to form a smooth paste. The slurry is coated onto thin metal foils (usually copper for the anode and aluminum for the cathode) and dried in a controlled environment to remove the solvent. Finally, the coated foils are compressed between rollers to reach the required thickness and density — a process known as calendering.

The electrode manufacturing stage includes three main steps: slurry preparation, coating and drying, and calendering. During slurry preparation, active materials are mixed with a solvent and binder to form a smooth paste. The slurry is coated onto thin metal foils (usually copper for the anode and aluminum for the cathode) and dried in a controlled environment to remove the solvent. Finally, the coated foils are compressed between rollers to reach the required thickness and density — a process known as calendering.

Most

Most