If you’ve ever walked with a plant manager and maintenance personnel taking care of a dust collection system and heard someone say, “We already have leak detectors, so we’re covered,” there’s a good chance two very different concepts are being mixed together.

Leak testing and broken filter detectors both deal with emissions and filter integrity, but they answer very different questions, operate on very different timelines, and serve different roles in a dust collection program. Confusing them can lead to missed failures, false confidence, or unnecessary downtime.

Let’s break down what each one actually does, when it should be used, and how they work together in real plants.

Leak Testing: A Snapshot in Time

Leak testing is a manual, periodic verification method. It’s designed to answer one specific question: Is the collector leaking RIGHT NOW?

Most commonly, leak testing involves introducing a fluorescent powder or tracer into the inlet of the dust collector while it’s operating. The clean air plenum, tubesheet, doors, seams, and other potential leak points are then inspected using UV light to see where powder is getting through.

Dominick Dal Santo, Dust Collection Expert at Baghouse.com, puts it plainly: “Leak testing is one of the best tools we have to confirm installation quality and sealing integrity, but it’s a moment-in-time test. It tells you what’s happening TODAY, not what’s going to happen next week.”

This makes leak testing extremely valuable during:

- ✔️ Commissioning of a new collector

- ✔️ Startup after a filter changeout or major maintenance

- ✔️ Troubleshooting visible emissions or indoor dust complaints

- ✔️ Verifying NFPA or environmental compliance after modifications

However, once the test is over, the system goes back to normal operation, and anything that fails after that point goes unnoticed until the next inspection.

Real Life Leak Testing Scenario

Dusting in the clean air plenum

A cement plant replaces all filter bags during a planned outage. Everything looks good visually, but during startup they notice some dusting in the clean air plenum. A leak test reveals several minor leaks at door gaskets and a handful of bags that were pinched during installation.

The issues are corrected immediately, avoiding a compliance problem and saving the plant from weeks of chasing unexplained dust. In this case, leak testing does exactly what it’s meant to do: confirm workmanship and sealing before the plant moves on.

But once production ramps up, bag failures caused by abrasion, chemical attack, or pulse cleaning stress won’t be caught by leak testing alone.

Broken Filter Detectors: Continuous Awareness

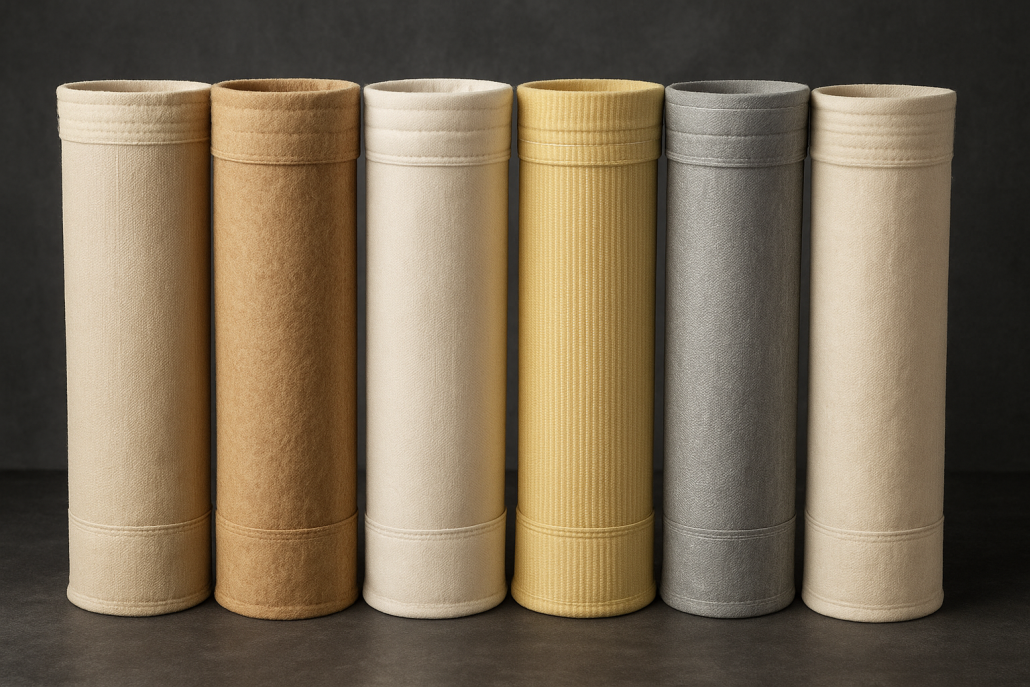

A entry level triboelectric broken bag detection system

Broken filter detectors (often triboelectric or electrodynamic sensors) are continuous monitoring devices. Instead of asking “Is there a leak right now?”, they answer a different question: “Did something change?”

These sensors are installed in the clean air duct or stack and continuously measure particulate activity. When a filter tears, a bag drops, or a cartridge cracks, the particulate level changes… and the detector flags it.

Matt Coughlin, President of Baghouse.com, explains it this way: “A broken filter detector isn’t about absolute emissions. It’s about trend deviation. It tells you that the system isn’t behaving the way it did yesterday.”

That distinction matters. Broken filter detectors are excellent at catching:

- ✔️ Sudden bag failures

- ✔️ Progressive filter degradation

- ✔️ Maintenance errors (like a bag left unseated)

- ✔️ Early warning signs before visible emissions appear

They don’t replace leak testing, but they cover the gap between inspections.

Real-World Monitoring Scenario

A metal foundry facility runs a baghouse handling fine particulate with tight OSHA exposure limits. Everything passes leak testing during annual maintenance. Six months later, a single filter develops a tear near the snap band due to vibration of the compressed air pulse jet.

There’s no visible plume outside, and no one notices dust inside the plant….yet. But the broken filter detector shows a slow, consistent upward trend. Maintenance investigates, finds the failed bag, and replaces it during a short planned stop. Without continuous monitoring, that single failure could have gone unnoticed for months.

Where Plants Get It Wrong

Dominick notes: “We see facilities assume a tribo sensor means they’re compliant. In reality, it just tells you something changed. You still need testing, engineering judgment, and an understanding of your process.”

On the flip side, some plants rely only on annual or semi-annual leak testing and assume that’s sufficient. In high-risk applications (combustible dust, silica, or recirculated air), that’s often not enough.

Another challenge is poor sensor placement or configuration. A detector installed too close to a fan, elbow, or turbulent area can produce noisy data that operators eventually ignore. At that point, the sensor exists—but it’s not actually protecting anyone.

Leak Testing vs. Broken Filter Detection

In a nutshell, leak testing is diagnostic and confirmatory. It finds where dust is leaking and allows you to physically fix it.

Broken filter detectors are protective and preventative. They alert you when performance changes, often before people or regulators notice.

Matt summarizes it well: “If leak testing is your inspection report, broken filter detectors are your smoke alarm. You wouldn’t choose one instead of the other.”

Our Technical Recommendation

For most industrial dust collection systems (especially those tied to compliance, recirculation, or combustible dust risk) the best approach is layered.

- ✔️ After major maintenance

- ✔️ During commissioning

- ✔️ When troubleshooting known issues

Broken filter detectors should be used:

- ✔️ On systems where downtime is costly

- ✔️ Where indoor air quality limits are tight

- ✔️ When early warning is more valuable than absolute measurement

And most importantly, both should be backed by people who understand how the system actually operates. Sensors don’t replace expertise. Tests don’t replace vigilance.

Leak testing and broken filter detectors aren’t competing tools. Plants that understand the difference build systems that are safer, more reliable, and easier to manage. If you’re unsure which approach—or combination—fits your operation, that’s usually a sign it’s time for a deeper look at the process, not just the equipment.

Here is where our expertise comes in handy!