Combustible dust remains one of the most underestimated hazards in industrial environments, despite decades of research, regulation, and high-profile incidents that highlight its destructive potential. As facilities scale production, add new materials, or modernize equipment, many unknowingly create the perfect conditions for fires, flash fires, and even catastrophic explosions.

Special Guest for our Webinar – Joe Kastigar, Regional Sales Manager of Boss Products

This FREE webinar brings together industry experts like Joe Kastigar, our special guest from Boss Products, to walk you through the essential concepts, modern technologies, and practical steps every facility must understand to manage combustible dust safely and responsibly. Here’s a quick overview of what will be explored.

Why Combustible Dust Still Deserves Your Full Attention

Manufacturers across woodworking, food processing, metals, agriculture, and paper have dealt with combustible dust since the Industrial Revolution. But major incidents in the last decades proved that even well-established operations can underestimate the hazard. These events triggered sweeping changes, including OSHA’s National Emphasis Program and continuous updates to NFPA standards.

Yet incidents still happen every year.

Why? Because identifying, testing, and controlling combustible dust is more complex than it seems, and each industry brings its own unique risks.

Key Concepts You’ll Learn During the Webinar

Is My Dust Combustible?

Matt will guide you through the fundamentals:

✔️ What makes a dust combustible?

✔️ What Is the Fire Triangle and the Dust Explosion Pentagon?

✔️ NFPA 660 Application Flowchart and how to use it

✔️ What “layers of protection” actually look like in a real facility?

This segment will help you understand whether your dust, process, and environment create conditions for ignition or explosion.

Fire Prevention Technologies: Stopping Ignition at the Source

This section includes the modern tools that prevent fires before they start, including:

✔️ Spark detection and extinguishing systems (Raptor Spark)

✔️ Firebreak shutters

✔️ Abort gates for safe airflow redirection

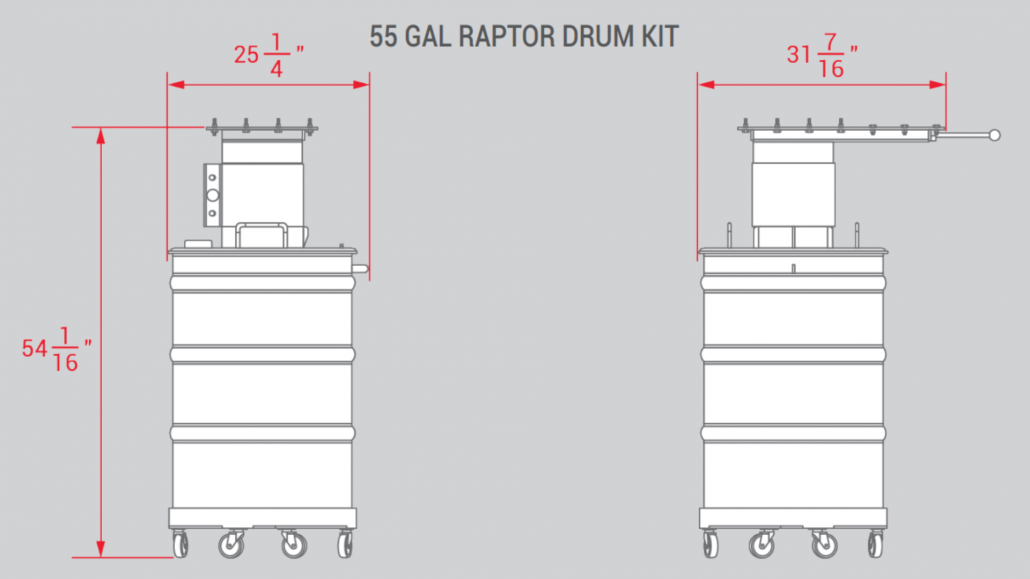

✔️ Explosion-tested drum kits

✔️ Spark traps

✔️ CO₂ fire suppression systems

These technologies are often the first line of defense, especially in high-risk processes involving wood dust, grain, metal fines, paper fibers, or food ingredients.

Explosion Protection: Containing and Controlling the Event

Fire prevention reduces risk, but it cannot eliminate it entirely. That’s where explosion protection becomes critical.

✔️ Explosion isolation valves to prevent propagation

✔️ Explosion vents and flameless vents for safe pressure relief

✔️ Active suppression systems that extinguish an explosion in milliseconds

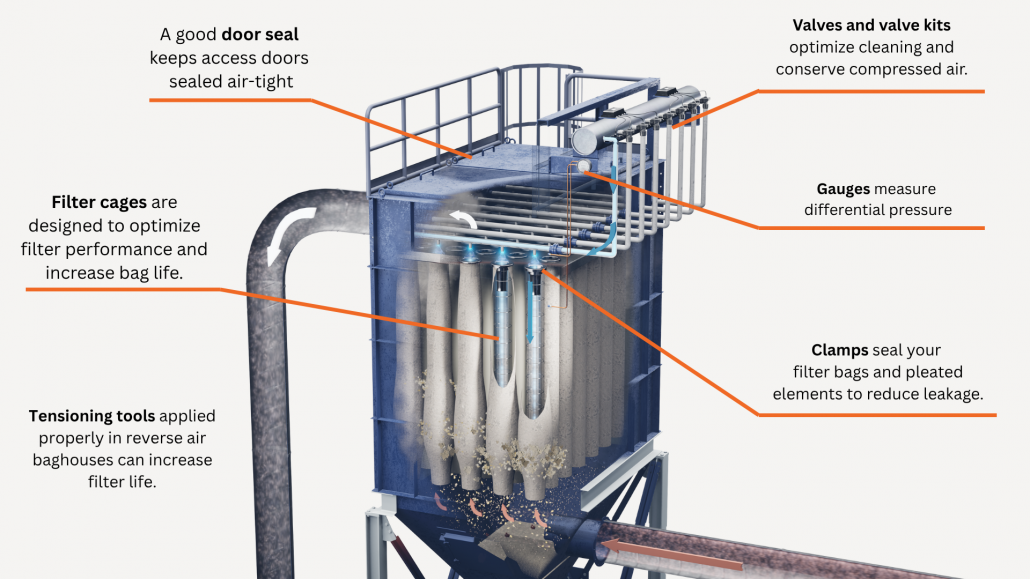

✔️ How these devices integrate with dust collection systems

This section helps facilities understand how to design or upgrade systems so a deflagration is contained rather than becoming a plant-wide disaster.

Industry-Specific Challenges

We will explore what combustible dust looks like across major industries:

✔️ Woodworking: embers, sanding dust, large duct systems

✔️ Food processing: organic powders, conveyors, mixers

✔️ Metalworking: aluminum and titanium fines, static, grinding operations

✔️ Agriculture: grain handling, silos, dryers, bucket elevators

✔️ Paper: dry fibers, trim systems, bale breaking

Each sector has different ignition sources, dust characteristics, and system challenges. This portion of the webinar helps attendees connect general principles to their real-world processes.

Implementation & Best Practices: Where Many Facilities Struggle

We will finish with the practical steps that turn knowledge into action, including:

✔️ How to conduct a Dust Hazard Analysis (DHA)

✔️ When retrofitting is enough—and when a redesign is needed

✔️ Essential maintenance routines for prevention and protection systems

This segment gives attendees a clear roadmap for moving from awareness to compliance and long-term risk reduction.

What You’ll Take Away

You’ll walk away with:

✔️ A better understanding of the dust in your facility

✔️ A clearer view of NFPA 660 and related standards

✔️ Practical fire and explosion mitigation options

✔️ A roadmap for improving safety, uptime, and compliance

How to Connect

Attending the webinar is easy! Simply register using the link below. Once registered, you’ll get a confirmation email with all the details to log in. Don’t miss it:

📅 Date: Wednesday, December 10th, 2025

⏰ Time: 1:00 PM (EST)

📍 Platform: Zoom

🔗 Registration Link: Click here.

The session will be interactive, with a live Q&A at the end, so be sure to come prepared with any questions you may have about combustible dust.

Combustible dust hazards aren’t going away. As materials change, production speeds increase, and automation grows, the potential for ignition and explosion becomes even more important to manage proactively. Through education, testing, prevention, and engineered protection systems, you can significantly reduce risk and safeguard both people and operations.

This webinar is your chance to get expert-guided clarity on what steps to take next—no matter your industry or facility size.