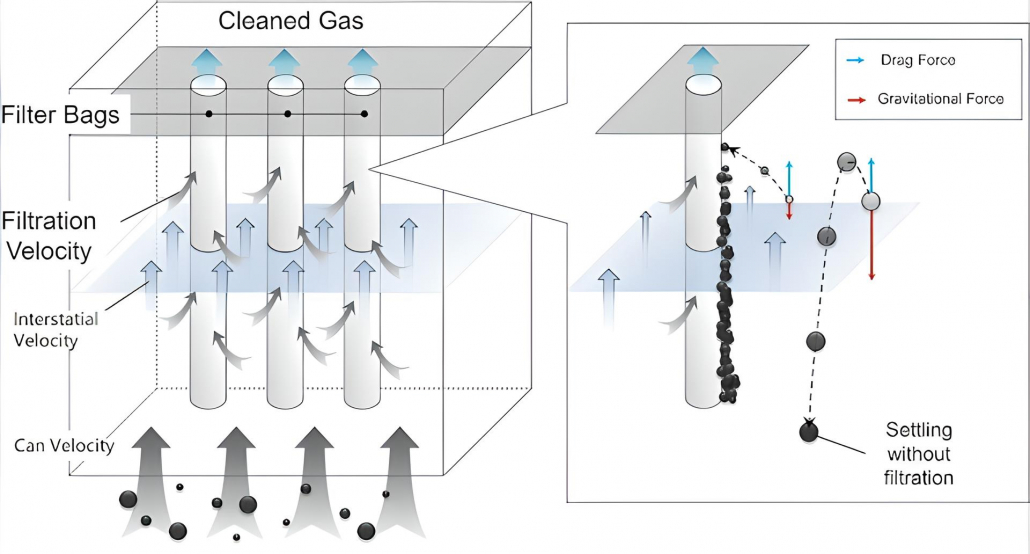

When designing a pulse-jet dust collector, engineers often focus on the air-to-cloth ratio as the main sizing parameter. However, there’s another equally important factor to consider: interstitial velocity and can velocity. Ignoring this variable can lead to significant performance issues, including poor dust release, higher energy consumption, and reduced filter life.

What is Interstitial Velocity?

Interstitial velocity refers to the upward velocity of air moving through the open spaces between the filter bags inside a dust collector.

Interstitial velocity refers to the upward velocity of air moving through the open spaces between the filter bags inside a dust collector.

This upward air movement occurs in systems that use a hopper inlet. In these configurations, dust-laden air enters through the hopper and flows upward into the filter housing. The clean air passes through the filter bags, while the dust accumulates on the outer surfaces of the bags.

The interstitial velocity can be calculated using the following formula:

Interstitial Velocity = ACFM ÷ ((Length × Width − π × (Bag Dia ÷ 2)2 × # of Bags) ÷ 144)

If the interstitial velocity is too high, dust that’s pulsed off during cleaning won’t fall back down into the hopper. Instead, it will remain suspended and be drawn back onto the bags. This leads to a high pressure drop, excessive compressed air usage, and shortened bag life.

What is Can Velocity?

Can velocity refers to the upward air velocity through the entire housing below the filter bags. In other words, interstitial velocity focuses on the air movement between the bags themselves, while can velocity measures the air movement just below them.

The can velocity can be calculated using the following formula:

Can Velocity = ACFM ÷ ((Side L × Side W) ÷ 144)

What Is the Optimal Interstitial Velocity?

There isn’t a single standard value for interstitial velocity. The optimal level depends on several factors, including dust characteristics and operating conditions.

- ✅ Bulk Density: Dusts with higher bulk density settle more easily, allowing for higher interstitial velocities.

- ✅ Particle Size: Smaller particles remain suspended longer, so lower interstitial velocities are preferred.

- ✅ Agglomeration Tendencies: If the dust tends to clump together, it may fall more easily, permitting slightly higher velocities.

- ✅ Inlet Loading: Both high and low dust loading rates can influence how much upward velocity the system can tolerate.

Each of these factors must be evaluated during the design phase to determine an acceptable range that keeps the collector efficient and prevents re-entrainment.

Optimizing Interstitial Velocity in New Dust Collectors

When designing a new dust collector, engineers typically start by dividing the system’s airflow by the desired air-to-cloth ratio to determine the required filter area. After that, the number, length, and diameter of the filter bags are selected. If the resulting interstitial velocity is too high, several adjustments can be made:

- Change Bag Length: Switching from 10-foot to 8-foot bags (or even shorter) can reduce upward air velocity.

- Change Bag Diameter: Using smaller-diameter bags (for example, 4½ inches instead of 5¾ inches) increases spacing between bags and lowers interstitial velocity.

- Use a High Inlet: A high inlet design introduces dust-laden air into the upper part of the housing, minimizing upward air movement.

- Increase Row Spacing: Widening the distance between bag rows (from the standard 8-inch centers to a greater spacing) helps reduce velocity between the filters.

Sometimes a combination of these methods is required. For instance, to achieve an interstitial velocity below 100 feet per minute, you might need to use shorter bags and increase bag spacing simultaneously.

Optimizing Interstitial Velocity in Existing Dust Collectors

Reducing interstitial velocity in an existing dust collector can be more challenging, but several modifications can still be effective:

- ✅ Switch to Smaller-Diameter Bags: This increases open space in the housing but requires a new tubesheet. Even though the air-to-cloth ratio increases, lowering interstitial velocity can still improve overall performance.

- ✅ Use Smaller-Diameter, Longer Bags: This maintains the same air-to-cloth ratio while expanding open space. However, housing modifications may be necessary.

- ✅ Reduce Air Volume: Adjusting the ventilation system to lower airflow (CFM) decreases interstitial velocity directly.

- ✅ Install Pleated Filters: Pleated elements offer much greater filter area, reducing both interstitial and can velocities. Some rows of filters can even be removed while maintaining or improving filtration efficiency.

Pleated elements offer much greater filter area, reducing both interstitial and can velocities.

These pleated filters are usually 40″ shorter than the bags, doubling the height in the drop-out zone. This increase allows large dust to settle before even entering the filter section, further reducing the load on the filters. When filters “see” less dust, they do not load up as quickly, they are not pulsed as frequently, and they last longer.

- ✅ Add a High Inlet Section: Retrofitting a high inlet effectively eliminates upward air velocity by changing the airflow path.

Careful consideration of interstitial velocity during the design phase can prevent costly performance issues and maintenance problems later.

For existing collectors, thoughtful retrofits and airflow adjustments can restore performance and reduce re-entrainment problems without requiring a full system replacement.

Keeping interstitial velocity under control is a small design detail that makes a big difference in achieving reliable, efficient, and long-lasting dust collection performance.