Interview With David Dal Santo, our Director of Operations

Director of Operations at Baghouse.com, David DalSanto

With decades of experience finding solutions to our customers’ often complex dust collection needs, Baghouse.com has acquired extensive experience overcoming obstacles foreseen and unforeseen.

Read what our Director of Operations, David DalSanto, who has been with the company since its inception nearly four decades ago, has to say about some of the most exceptional projects Baghouse.com has completed.

— "What former projects of Baghouse.com are you the most proud of having been a part of?"

— "What were some of the most challenging projects that you have tackled?"

Original condition unit with envelope filters and shaker mechanism

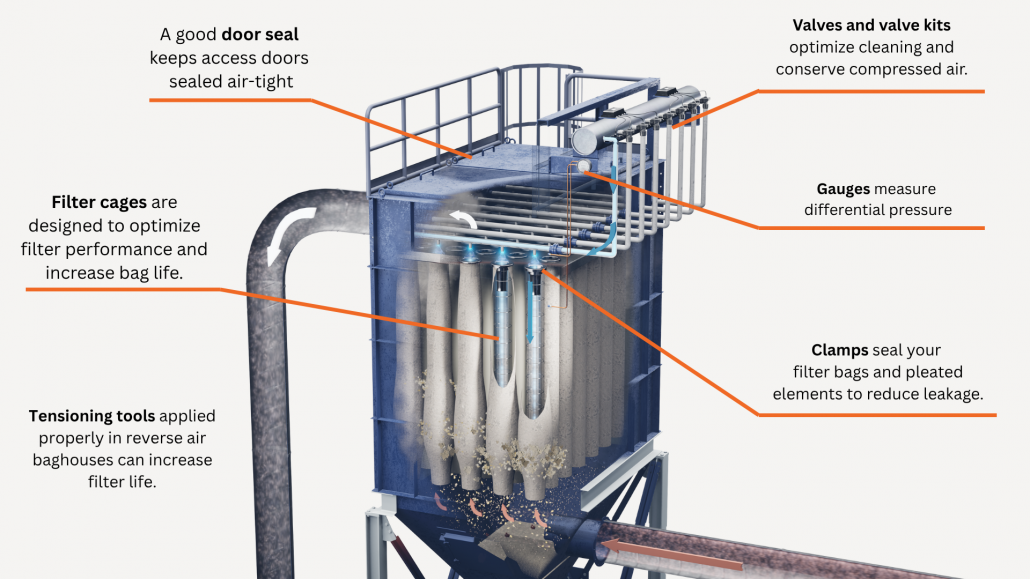

David – “Goodyear Tire & Rubber Co. – Topeka, KS – Old ‘Envelope” style Dust Collectors by W.W. Sly & Pangborn were a “maintenance headache” for the plant. We did multiple Pulse-Jet conversions to the existing Dust Collectors. By removing the inner workings and roof structures, we made room to install modern Clean Air Plenums. We modified the ductwork and installed High Efficiency Cylindrical filter bags and cages to take advantage of the Pulse-Jet cleaning system.”

— "What were the specific problems that you had to face?"

David – “Most units were in the center of a large building, an area that could not be serviced by conventional cranes.”

Follow Up Question — "How did you overcome those problems?"

As we couldnt use traditonal cranes, the collectors had to be installed using Helicopter lifts

David – “New equipment had to be installed using Helicopter lifts. As a licensed pilot/aircraft owner myself, I know well just how dangerous these aerial maneuvers are, and the great skill, and expertise that are needed to execute these operations safely. Despite all of the challenges we faced to get this Baghouse back up and running, downtime for each conversion was only 3 to 4 days each. Again remarkable considering the circumstances.”

— "What do you feel are some of the greatest dangers you know of regarding safety on the job site, and how do you handle them?"

David – “Several dangers present themselves regularly in our line of work. #1 – Harmful gasses leaking into the work area. #2 – Unsafe structures/hazard of falling objects. #3 – Fire hazards during welding/cutting operations. We work with our foremen, safety personnel and plant representatives to identify all of these dangers specific to each job before we begin. We then brief our people accordingly, enabling them to keep a close watch for these hazards and avoid them.”

Identifying all the dangers specific to each job before we begin is one of the most important routines of our team

“The greatest danger we encounter however is; unsafe materials hoisting practices by plant or outside contractor personnel. Because of my personal experience as a Structural IronWorker and Heavy Machinery Mover, I know full well the immense danger to life that this process poses. I have seen first hand the tragedy that results when people who are not qualified to carry out this task, or simply have a disregard for lifting/hoisting safety measures.”

“As such, we prefer to do our own lifting/hoisting. All of which is directly led by a duly trained foreman, with extensive training and experience conducting these lifts safely and properly.”

— "What are some of the biggest mistakes you notice other companies make when servicing a Dust Collector?"

Some of the biggest mistakes we notice other companies make when servicing a Dust Collector is to tension the structural filter bags incorrectly.

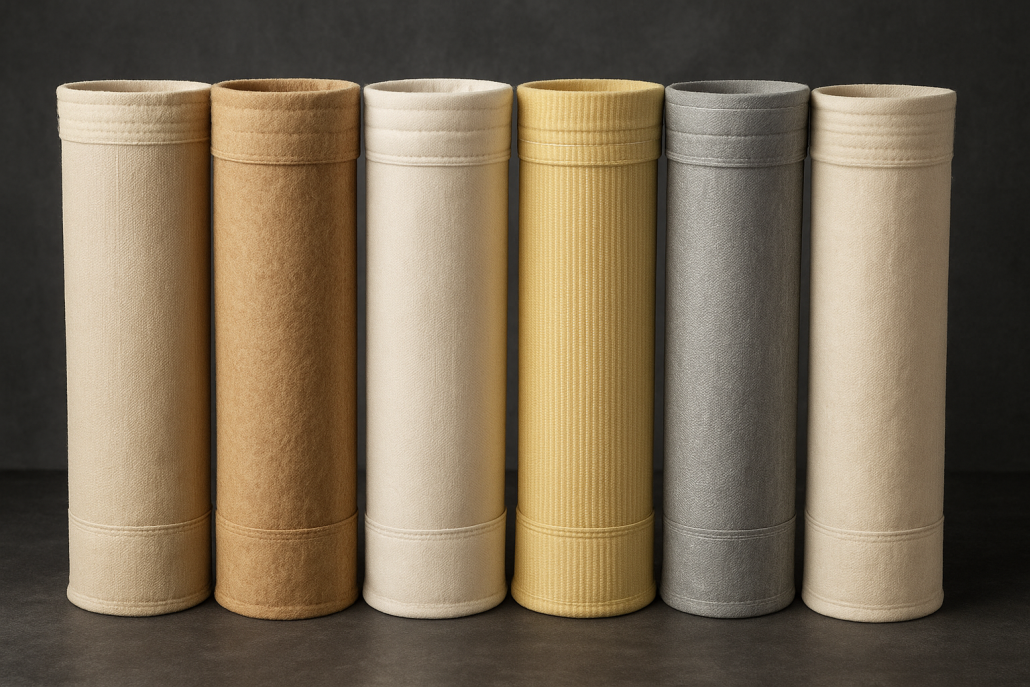

David – “#1 – Incorrect handling/installation practices on specialty filters such as Fiberglass and PTFE Membrane media. #2. Incorrect tensioning procedures on structural filter bags. #3 – Incorrect start up settings/procedures and Incorrect operations procedures.”

“In many cases we are called to fix another company’s mistakes. We often find that a rushed operation, or an overall lack of technical expertise & attention to detail on account of the contractor has caused many problems. These shortcomings later on, needed to be corrected by Baghouse.com during subsequent maintenance visits.”

— "What would you say makes Baghouse.com different from your competitors?"

David – “We care about our customers and we do everything possible to help get their operation running as efficiently as possible or get them back up and running quickly after problems do arise.”

“We have a long history of successfully responding to emergency breakdown situations in which we were able to get the customer back into operation quickly with minimal downtime and lost productivity. This is no easy task, and you will be hard-pressed to find another company capable of duplicating our successes in this area.”

“We also have initiated many Regular Maintenance Programs, Environmental Emissions & Energy Audits, that to this day continue saving our customers money through avoiding violations and unplanned downtime, and increasing efficiency.”

“At the end of the day, we don’t just fix problems – we fix them fast, efficiently, and with a little bit of creativity…It’s not always glamorous, but hey, someone has to get the Baghouse back up and running!

We’ve seen it all, done it all, and if we don’t know the answer right away, we’ll find it. We are always ready for the next challenge.”