By Dominick Dal Santo

If you’ve ever walked past your dust collector and felt a blast of air strong enough to knock off your hard hat, it’s probably your air headers crying for help.

Rusty compressed air header in a dust collector

Recently, on a site visit, I came across headers so corroded and leaky they looked like they’d been through a war zone. The technician walking with me casually mentioned, “Oh yeah, we patch those a few times a year.” In fact, they were so used to leaks, they had makeshift braces holding the headers down to keep them from rattling loose during pulse cleaning. No pressure gauge in sight, just a whole lot of compressed air going to waste.

Let’s talk about how to prevent that from happening to your system — or how to fix it if it already has.

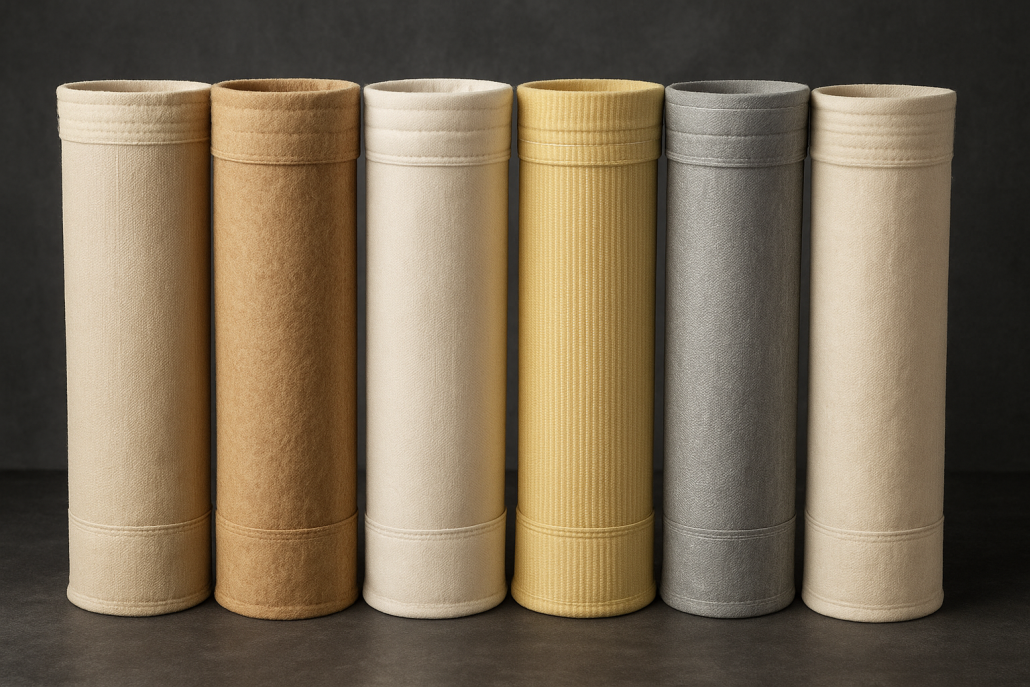

Why Air Headers and Pulse Valves Matter

rusty air header

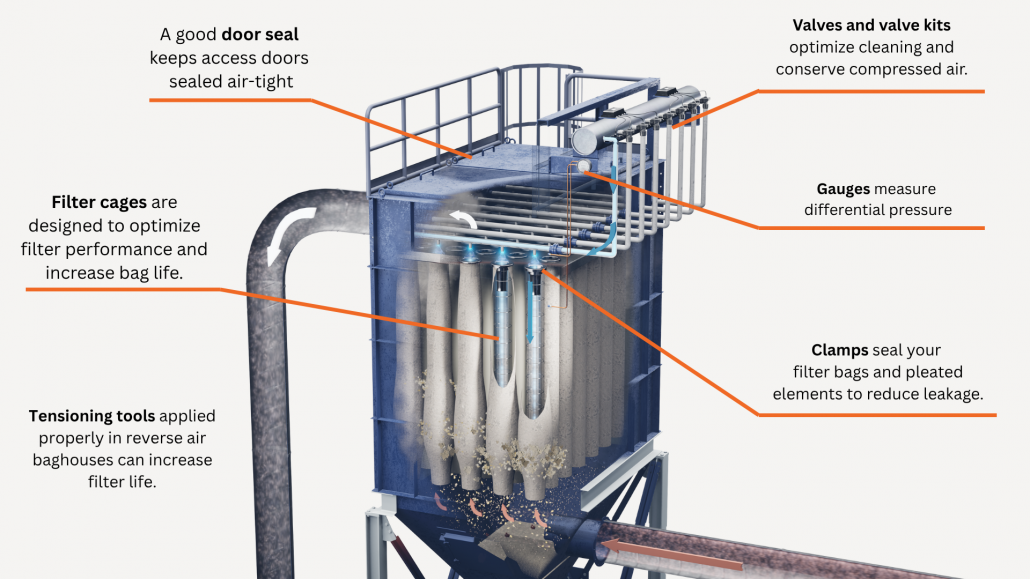

Pulse-jet baghouses rely on clean, high-pressure air stored in headers to deliver sharp bursts through pulse valves. These bursts keep your filter bags clean and your system breathing easy. But if the headers are corroded, leaking, or the valves are misfiring, you’re not cleaning — you’re wasting energy, damaging bags, and likely spending way more than you think.

Read more: The Importance of Correct Compressed Air Pressure in a Pulse Jet Dust Collector

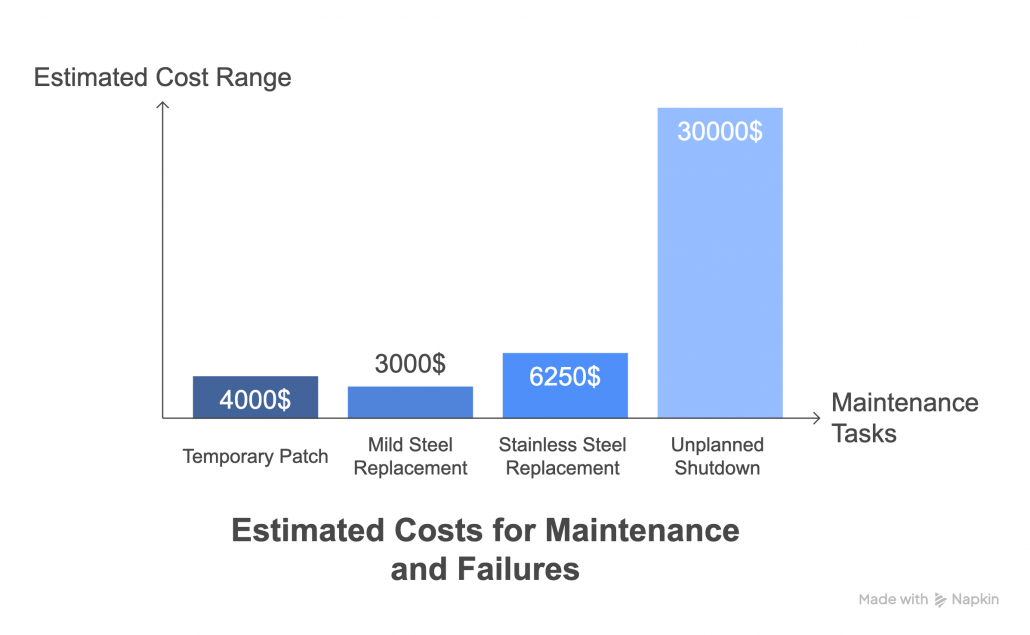

The Real Cost of Doing Nothing

Patching up air headers over and over might seem like a budget-friendly solution — until you count the cost of compressed air loss, labor, lost efficiency, and unplanned downtime.

Here’s a ballpark comparison:

Task | Estimated Cost |

Temporary patch (3x/year) | $3,000–$5,000 (labor + air loss) |

Replacing header with mild steel (again) | $2,000–$4,000 |

Replacing with stainless steel once | $5,000–$7,500 |

Unplanned shutdown due to failure | $10,000–$50,000+ |

The numbers add up quickly. And that’s without counting the frustration of explaining to upper management why another baghouse went down in the middle of production.

Why Stainless Steel Is Worth It

Stainless steel air headers not only look fancy, they’re functional. They resist the corrosion that eats away at mild steel, especially in humid or outdoor conditions. Install them once, and they’ll likely outlast the bags themselves.

Important tip: When installing SS headers, avoid contact with dissimilar metals (like carbon steel mounts or fasteners). Use insulating wraps or gaskets. Otherwise, you’ll get galvanic corrosion, and you’ll be right back where you started — but now with a more expensive problem.

Water in Your Lines?

One of the leading causes of internal corrosion in air headers is water in the compressed air lines. It sneaks in from improperly drained receivers, faulty dryers, or sometimes just plain humid air.

Purge valves or auto-drains at the bottom of your headers automatically open to release the water, helping to get rid of this moisture before it can collect and cause corrosion. If you don’t have these — it’s time.

What About the Pulse Valves?

Routine inspection and replacement of pulse valves and diaphragms (typically every 1–2 years, depending on conditions) keeps your cleaning sharp and efficient.

Your pulse valves are the workhorses of the cleaning system. But if they’re sticking, leaking, or misfiring, they’ll throw your firing sequence off — and cleaning gets spotty. That means:

- 🔹 Bags cake up

- 🔹 Differential Pressure goes up

- 🔹 Fan has to work harder

- 🔹 Energy bills climb

- 🔹 Filter life drops

Routine inspection and replacement of pulse valves and diaphragms (typically every 1–2 years, depending on conditions) keeps your cleaning sharp and efficient.

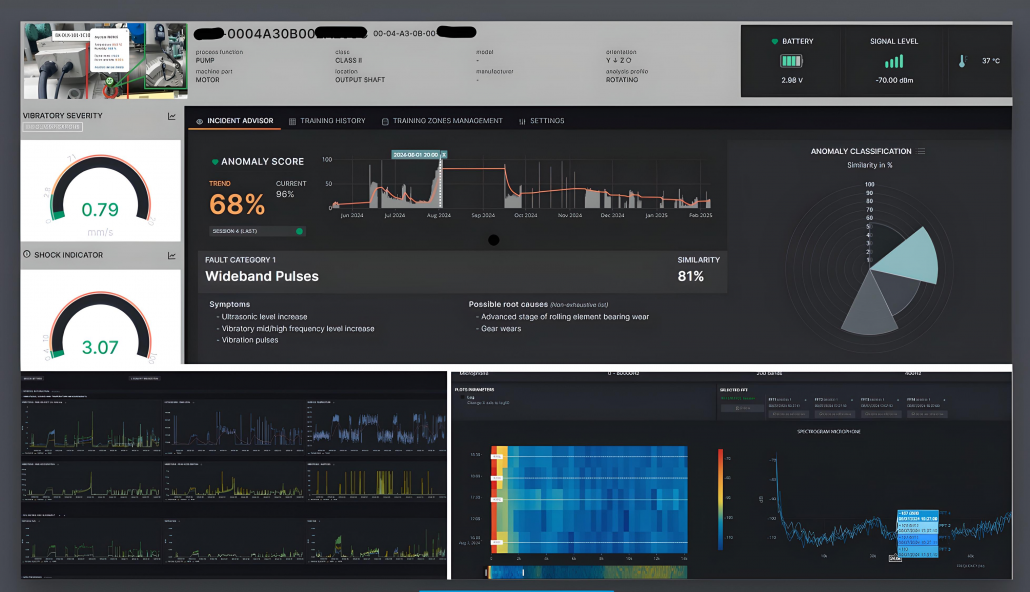

Multiple Headers? Sync the Firing Sequence

If your collector has multiple air headers, it’s critical that your pulse control system fires valves in sequence — not all at once. Simultaneous firing can cause a pressure drop across all headers, making pulses weak and ineffective.

A simple test: For most applications using felted filter media, compressed air at roughly between 70 and 100 PSI may be recommended for proper cleaning of the filter elements. Check that pressure holds steady (or quickly recovers) during a full cleaning cycle. If it’s dropping like a rock, you’ve got either misfiring valves, leaks, or undersized air supply.

A Little Prevention Goes a Long Way

If your baghouse is a central part of your operation, then keeping your headers, valves, and air lines in top shape it’s essential.

Stainless steel headers, moisture control, working purge valves, and a good pulse sequence setup will pay for themselves in a year or less. And maybe, just maybe, you’ll get to keep your hard hat on next time you walk past the collector.