Why Consume Expensive Downtime To Precoat Your Dust Collector’s New Filters?

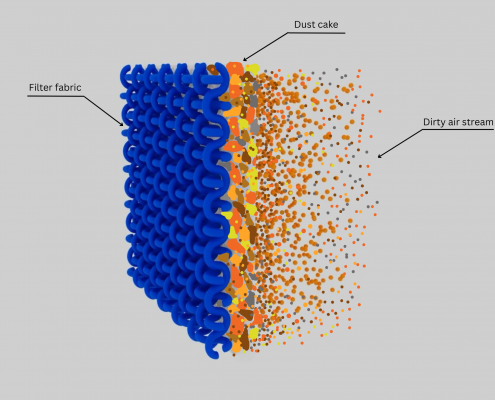

One good reason: Dust and fine particles 0.5 microns or smaller can leak right through a new bag or cartridge filter’s pores, working their way deep into the media to the point of clogging the filter and slowing or stopping airflow through your collector.

So if your dust particles are smaller than 10 microns, taking the time to precoat your new filters’ surface with a dry precoating material is the smart thing to do.

Precoat powder is a fine, inert material—typically made of substances like cellulose or diatomaceous earth—used in dust collection systems to protect and enhance filter performance. It is applied as an initial layer on new filter bags or cartridges before the system begins collecting process dust.

Common pre-coat materials include:

Expanded Perlite

.

Expanded Perlite: Absorbs sticky residues and hydrocarbons while providing a porous barrier.

.

.

.

.

Diatomaceous Earth

.

Diatomaceous Earth: Known for its fine particle capture and moisture-absorbing properties.

.

.

.

.

Calcium Carbonate

.

.

Calcium Carbonate: Neutralizes acidic contaminants and provides an effective protective layer.

Benefit: Longer Filter Life

When your dust stream contains a significant percentage of submicron particles, precoating can reduce or prevent the premature failure of your new filter media. Precoating material will build up an initial dust cake on the filter, preventing dust particles from flowing into and clogging the media.

Typical service life for bag filters without precoating is 1 to 3 years and for cartridge filters is 3 to 12 months. Depending on the application, precoating can extend the filter’s life substantially providing enormous cost savings in replacement filters and changeout labor.

Precoating material will build up an initial dust cake on the filter, preventing dust particles from flowing into and clogging the media.

Precoating new filters provides other benefits, too. By keeping particles on the filter surface, precoating improves the initial filtering efficiency at startup. Precoated filters are easier to clean and provide better dust cake release for applications with process air that contains moisture, hydrocarbons, or both. Precoating materials, which don’t burn, can be applied to filters made of fire-retardant media to help reduce explosion risks in spark-producing processes, such as milling.

So, as a review, the main benefits can be summed up as follows:

- ✅ Sets up consistent porous dust cakes throughout all the filters.

- ✅ Absorbs moisture and oils that can shorten bag life.

- ✅ Safe to handle, lightweight powder remains on the filter bags.

Pore Opening Size and Particle Size

Now that we have analyzed the benefits, there are two additional factors you should know when deciding to precoat your filters:

- 🔶 The pore openings in bag filter media are usually larger than in cartridge filter media, so precoating is required more commonly for bag filters than for cartridge filters. For example, the pore openings in a 16-ounce polyester bag filter are 19.675 microns, significantly larger than the 10.253-micron pore openings in a comparable 80-20 polyester blend (80 percent cellulose, 20 percent polyester) cartridge filter.

- 🔶 The smaller your dust particles are, the more important it is to consider precoating your filters. And depending on the kind of size analysis used for determining your dust’s size distribution, the particles may be smaller than you think.

The true filtering surface is not the bag itself, but the dust layer or filter cake. When adding a precoating material, you make sure that even the smallest particles are captured by the filter.

Instructions For Precoating Your Filters

The method for precoating new bag or cartridge filters is relatively simple and doesn’t require any special equipment. After installing the new filters in your dust collector, you simply run the collector fan at a low volume to draw precoating material into the collector and onto the filters. For a baghouse or large cartridge collector, this process typically takes 3 to 4 hours; for a small cartridge collector, it can take just 30 to 60 minutes.

The method for precoating new bag or cartridge filters is relatively simple and doesn’t require any special equipment.

Step by step

Whether you’re precoating bag or cartridge filters, the procedure is the same. After installing your new filters in your baghouse or cartridge collector, follow these steps:

For Collectors With A Full Set Of New Bags:

- With the fan running, the cleaning mechanism off, and the process off, inject Baghouse.com precoat powder into the system.

- With the cleaning mechanism remaining off, bring the process online.

- Operate under normal conditions and allow differential pressure to reach 4” to 5” w.c.

- Monitor differential pressure across the collector. It may be possible to reduce the frequency and/or duration of cleaning and maintain adequate differential pressure. This may extend filter bag life.

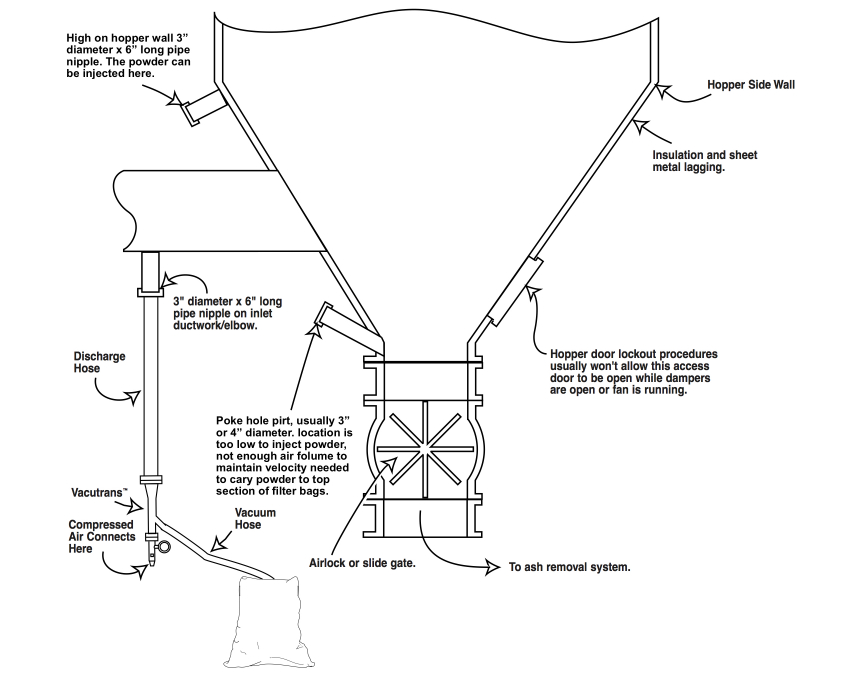

Some hoppers have an inlet above the discharge. Although many people are tempted to inject the precoat powder through this inlet, it is a very low location, there is not enough air volume to maintain the velocity needed to carry powder to the top section of the filter bags

For Bag Recovery And Spot Changing Online Cleaning Collectors (Pulse-Jet Only):

- Turn off the fan and run the system through the cleaning cycle two or three times to purge the excess particulate. Turn off the cleaning system after purging the collector and leave it off through step 5.

- With the process off, restart the fan and inject Baghouse.com precoat powder into the system.

- With the cleaning mechanism remaining off, bring the process back online.

- Operate under normal conditions and allow differential pressure to reach 4” to 5” w.c.

- Turn the cleaning system on. Monitor differential pressure across the collector. It may be possible to reduce the frequency and/or duration of cleaning and maintain adequate differential pressure. For better cleaning on pulse-jet applications, stagger the row pulsing to prevent re-entrainment of particulate onto the bags.

Off-Line Cleaning Collectors (Reverse Air, Shaker, And Pulse-Jet)

Individually isolate the inlet and outlet of the compartments that will receive the injection and manually run through the cleaning cycle two or three time.

- Turn off the cleaning mechanism in each compartment and leave it off until step 6.

- The outlet of the compartment should be opened on negative systems. On positive systems, both the inlet and the outlet to the compartment should be opened.

- Inject Baghouse.com precoat powder into your system.

- With the cleaning mechanism still locked out, the isolated compartment should be returned to service. The pressure drop should be allowed to build up to the normal operating differential pressure before the cleaning mechanism is reactivated.

- Turn the cleaning system on. Due to increased airflow and decreased differential pressure, it may be possible to reduce the frequency and/or duration of cleaning. This may extend filter bag life.

NOTE: DO NOT SHUT OFF THE COLLECTOR FAN FOR A MINIMUM OF 8 HOURS AFTER THE PRECOAT POWDER INJECTION! The precoat powder may dislodge and fall into the collection hopper if the fan is shut off.

Calculating and Applying Precoat Powder

Precoat powder comes in 50-lb bags.

A good rule of thumb is to use one pound of pre-coat for every 20 square feet of baghouse filter media. Operate the system at 50% of the design airflow to the baghouse. This results in an inlet duct velocity of approximately 2000 FPM. Avoid dropping the velocity below this threshold.

The material should not be “dumped” into a system. Use a pre-coat feed rate of 1/3 pound per minute per 1000 CFM of reduced airflow. For instance, for a 25,000 CFM reduced airflow system, the feed rate would be 7.5 lbs./minute.

Calculations for Application

Bag Diameter (inches) x 3.1416 = Circumference

Circumference (inches) x length (inches) = Inches² Per Bag

Inches² / 144 = Feet² Per Bag

Feet² x Total Number of Bags = Total Feet²

Total Feet² x .042 lbs = Precoating agent (pounds) Required

Inspecting and Verifying Precoat Coverage

After applying the pre-coat, isolate each filter compartment and inspect the filter bags to confirm they’ve developed a uniform coating

After applying the pre-coat, isolate each filter compartment and inspect the filter bags to confirm they’ve developed a uniform coating—ideally about 1/16 inch thick. It’s also important to check the dust collector hopper to ensure there hasn’t been excessive pre-coat material dropout, which could indicate uneven distribution or overfeeding.

Once the inspection is complete and coverage is confirmed, gradually increase the airflow to the system’s design-rated volume. At this point, you can reactivate the dust discharge equipment, such as the airlock. However, hold off on restarting the filter bag cleaning system until the differential pressure across the bags reaches 3 to 4 inches. This delay allows the pre-coat to settle and form a stable dust cake on the filter media before the first pulse cleaning cycle begins.

Conditioning Feed Of Precoat Powder

After the initial injection, Baghouse.com precoat powder can be added on a continuing basis as a conditioning feed to improve overall long-term collection efficiency and absorb damaging moisture. This provides improved porosity of the dust cakes, resulting in better airflow while reducing bag blinding and depth penetration that can shorten filter bag life.

Although every case is site-specific, the following formula applies for conditioning feed: