El sector industrial es un área que con frecuencia tiene dificultades para encontrar formas de volverse más ecológico.

Encontrar nuevas maneras de que las empresas reduzcan su impacto ambiental es vital en un mundo cada vez más consciente de la sostenibilidad. Aunque muchas compañías pueden implementar varios métodos para disminuir su impacto ambiental, otras están limitadas debido a la naturaleza de sus procesos. El sector industrial es uno de esos casos donde frecuentemente es difícil encontrar maneras de volverse más ecológico.

A menudo, no pueden reducir directamente su consumo eléctrico debido a la naturaleza de su proceso. Tal vez las regulaciones de seguridad impiden que disminuyan el uso de luminarias incandescentes, o el proceso de manufactura simplemente no puede operar sin una gran cantidad de electricidad (por ejemplo, fundición de metales pesados).

¿Hay algún método que estas empresas puedan usar para reducir su impacto ambiental sin sacrificar la producción ni la seguridad?

Disminuir el impacto ambiental mediante un sistema de colección de polvo eficiente

Una forma sencilla de que las empresas reduzcan su impacto ambiental es mejorando la eficiencia de sus colectores.

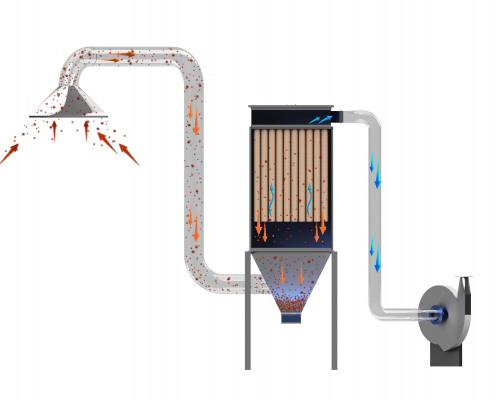

Un sistema de recolección de polvo se utiliza para capturar partículas generadas en procesos industriales antes de que escapen a la atmósfera. Esto se logra mediante un ventilador de gran capacidad que crea un vacío en el sistema de ductos a lo largo de la planta.

Diagrama que muestra un sistema de colección de polvo completo, desde la tomada del aire sucio, los filtros y el ventilador

En cada punto donde se genera polvo (molinos, puntos de transferencia [elevadores, bandas transportadoras, etc.], chimeneas de extracción, etc.), el aire es aspirado por campanas de ventilación para llevarlo al colector. Una vez dentro del colector, el aire sucio pasa a través de una serie de filtros que remueven las partículas. Finalmente, el aire ya limpio se libera a la atmósfera exterior.

Por ley, casi todas las instalaciones industriales deben contar con estos sistemas por razones de seguridad y protección ambiental. En la mayoría de los casos, el polvo generado por los procesos industriales se considera un contaminante que no puede liberarse al ambiente. Esto es especialmente cierto cuando se generan polvos peligrosos, (con químicos, metales pesados, etc.) o altamente combustibles (como harina, azúcar, polvos metálicos, etc.).

Este proceso requiere una gran cantidad de energía. Al maximizar la eficiencia del sistema completo, los operadores pueden reducir significativamente el consumo energético, disminuir el mantenimiento requerido, reducir el desgaste y, al mismo tiempo, aumentar la capacidad de operación e incluso el potencial productivo de la planta.

Estrategias para mejorar el rendimiento de tu colector de polvo

Podrías pensar que un sistema tan complejo requiere enormes inversiones para mejorar su eficiencia. “La verdad es que existen varias opciones sencillas que pueden aumentar la eficiencia del colector hasta en un 20%”, dice Dominick Dal Santo, Director de Ventas de Baghouse.com. “Algunas son tan simples como instalar medidores para monitorear presión, flujo de aire y el estado de los filtros. Otras requieren usar esos datos para ajustar los ciclos de limpieza del colector para que sean más eficientes”. También destacó que el costo de instalar estos instrumentos es mínimo y que personal interno, como electricistas, puede hacerlo fácilmente.

“En la mayoría de los casos, el mejor retorno de inversión viene de ajustar bien los parámetros del sistema de limpieza”, comenta Dominick. La mayoría de los colectores utilizan pulsos de aire comprimido para limpiar la acumulación de polvo en la superficie de los filtros. “Mientras más polvo se acumula, más esfuerzo debe hacer el ventilador para mover el mismo volumen de aire”. Es necesario encontrar un equilibrio entre limpiar con suficiente frecuencia (para mantener baja la resistencia), limitar el número de pulsos (para reducir el uso de aire comprimido, que suele ser costoso), evitar bajar la eficiencia de colección (pues se necesita cierta capa de polvo para capturar partículas) y minimizar el desgaste de los filtros (pues cuanto más agresiva es la limpieza, menor la vida útil).

“Ajustar correctamente el sistema de limpieza es un acto de equilibrio muy complejo, pero encontrar el punto óptimo es clave para reducir el costo de operación del sistema de colección”, comenta Dominick. En muchos casos, una planta contrata asesores técnicos especializados en colectores para determinar los mejores ajustes según cada situación.

Otros métodos sencillos incluyen verificar que se están usando los filtros adecuados. “Muchas plantas escatiman al inicio y compran filtros más baratos que no cumplen con sus necesidades”. Dominick menciona que muchas plantas podrían beneficiarse enormemente al cambiar a tecnología más reciente, como las membranas de PTFE. “Estos filtros con membrana PTFE duran mucho más que los tradicionales, se limpian más fácil (requieren menos energía para hacerlo) y capturan más partículas”.

Otra solución efectiva es cambiar de filtros tradicionales a filtros plisados, que permiten mayor área filtrante en el mismo espacio. Estos pueden aumentar la capacidad del sistema sin construir un colector nuevo, reducir el desgaste, incrementar la eficiencia de captura y disminuir el costo de instalación y mantenimiento.

¡Podrías disminuir el consumo de energía hasta en un 20%!

Reducir un 20% el costo energético del colector puede parecer poco, pero a escala industrial significa ahorros enormes. Veamos dos ejemplos.

Supongamos que una planta implementa algunos de los métodos mencionados y logra aumentar el tiempo entre pulsos de limpieza (reduciendo así el uso de aire comprimido y el esfuerzo del ventilador). ¿Cuánto puede ahorrar al año solo en energía?

Eficiencia en la limpieza

Tamaño del colector

Número de filtros: 144

Filas: 12

Valvulas: 1 y 1/2 dedoble diafragma

Costo de electricidad: $0.07

Costos de electricidad del ventilador

Flujo de aire del sistema: 11,000 CFM

Presión estática: 12 pulgadas

Costos de aire comprimido

Presión del pulso: 100 psig

Cantidad de pulsos al mismo tiempo: 1

Tiempo entre pulsos: 5 segundos

BHP utilizados: 33.3

Pulse pressure: 100

Número de pulsos al mismo tiempo: 1

Tiempo entre pulsos: Actual 5 - Nuevo 7.5

BHP: 5.00

Ahorro por día: $5.82

Ahorro anual en aire comprimido: $2,094.77

Ahorro anual en energía del ventilador: $2,539.00

Mejorando un solo aspecto del sistema, esta planta puede ahorrar $4,633.77 al año, sin contar mayor vida útil de filtros, mejor rendimiento y menor mantenimiento. En plantas grandes, donde el sistema puede ser 100 veces mayor, estos ajustes podrían traducirse en millones de dólares en ahorros anuales.

Todas las compañías (incluidas las plantas industriales) pueden encontrar maneras de mejorar su eficiencia energética y reducir su impacto ambiental. Aunque en algunos sectores es más difícil, siempre existen oportunidades. Para las plantas industriales, donde las opciones suelen ser limitadas, mejorar la eficiencia del sistema de colección de polvo suele ser una manera increíblemente fácil de reducir el impacto ambiental mientras se aumenta la producción, se reducen las interrupciones y se bajan los costos operativos.

¿Que es mejor, los filtros tradicionales o los filtros plisados?

Los filtros tradicionales suelen ser los más baratos por unidad, pero con los filtros plisados el costo total —a corto y largo plazo— para reemplazar y mantener tu colector de polvo puede bajar muchísimo.

Cambiar de filtros tradicionales a filtros plisados puede disminuir significativamente el consumo de energía y los costos de mantenimiento. Esto es lo que muestran los números:

Primero, el consumo energético se reduce de forma notable: en la comparación, el sistema con filtros comunes de manga o bolsa consume alrededor de $72,392 en energía, mientras que el sistema con filtros plisados usa $43,659. Eso es una reducción del 40%. La razón principal es que los filtros plisados tienen mayor área filtrante en el mismo espacio,lo que permite que el aire fluya con menos resistencia. Con menor restricción, el ventilador trabaja menos y consume menos energía. Menos carga al ventilador significa menor gastos en energía.

Segundo, los filtros plisados son más económicos de mantener a largo plazo. Aunque su costo inicial es mayor ($6,336 vs. $4,480 de las bolsas o mangas), se ahorra en mano de obra y en reemplazos. Los filtros plisados suelen durar más y son más fáciles de instalar, reduciendo los costos de mano de obra casi a la mitad ($900 vs. $2,700). Además, al mantener un flujo de aire más estable, reducen el desgaste del sistema de limpieza y prolongan la vida de componentes.

En total, el costo mensual operativo baja de $1,658 a $1,060, ahorrando casi $600 al mes (más de $7,000 al año) mientras mejora el rendimiento del sistema y se reducen las interrupciones.

Filtros de manga o bolsa

Actividad 0 12 24 36 48 total

Material/Tela 2,240 2,240 4,480

Mano de obra 1,350 1,350 2,700

Energía 72,392 72,392

Costo Mensual $1,658

Filtros Plisados

Actividad 0 12 24 36 48 total

Material / Tela 6,336 6,336

Mano de obra 900 900

Energía 43,659 43,659

Costo mensual: $1,060

Ventajas de cambiar a filtros plisados

Reduce costos hasta en un 60%.

Muchos creen que los filtros antiguos ahorran dinero… pero no es así.

Los filtros plisados:

✅ Reducen costos de energía y operación hasta en un 50%.

✅ Necesitan menos filtros en total.

✅ Baja los costos de mano de obra y reemplazo.

✅ Usan menos aire comprimido.

Diseñados para producción moderna y de alta demanda. Sustituyen a las mangas y jaulas existentes sin necesidad de modificaciones costosas.

Capturan más polvo gracias a su mayor área filtrante y duran hasta el doble que las mangas tradicionales.

Menos filtros, menos trabajo. Menor tiempo y costo de mantenimiento.

No requieren modificaciones al sistema: solo instálalos y empieza a ahorrar.

Hay muchas otras formas de reducir el consumo de energía y mejorar el rendimiento del sistema de colección de polvo además de las mencionadas aquí. La clave es saber dónde mirar, y ahí es donde la asesoría experta puede marcar toda la diferencia.