En plantas de cemento, fundiciones, procesamiento de alimentos, instalaciones metalúrgicas e incluso talleres de carpintería, hay un problema común: los sistemas de colectores de polvo parece que fallan siempre en el peor momento. Los motores se traban sin previo aviso. Los ventiladores empiezan a vibrar hasta generar reparaciones costosas. Los filtros se tapan y la producción se detiene por completo.

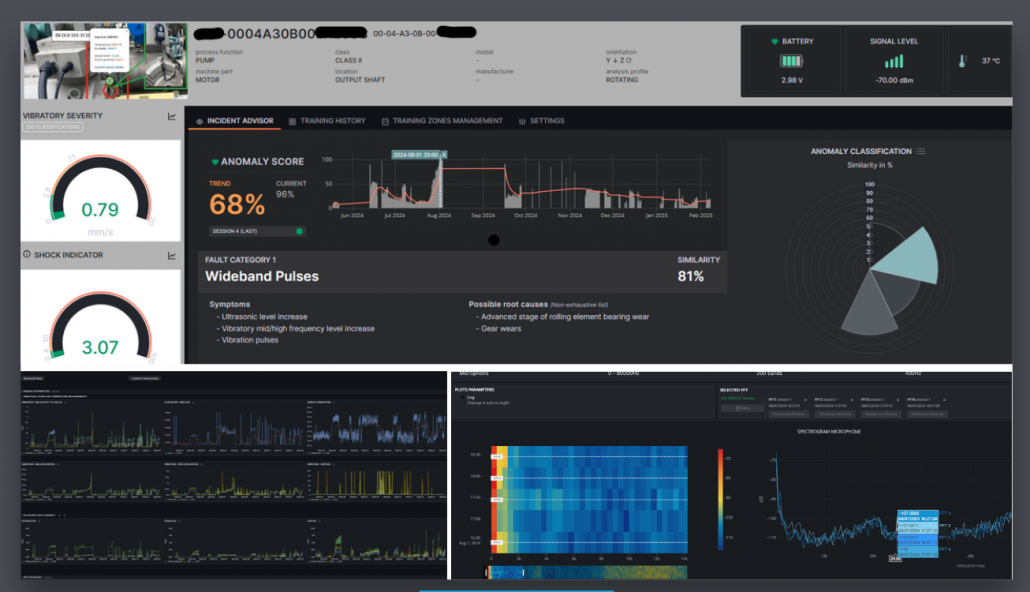

Hoy, sin embargo, los sensores remotos y el monitoreo en la nube están cambiando la forma en que las plantas mantienen sus sistemas. En lugar de reaccionar después de una falla, ahora es posible anticipar los problemas con días o incluso semanas de anticipación.

“El IoT finalmente les da a los equipos de mantenimiento la visibilidad que siempre necesitaron”, dice Matt Coughlin, propietario de Baghouse.com. “Cuando realmente puedas ver qué está pasando dentro de tu colector de polvo en tiempo real, dejarás de adivinar y empezarás a prevenir problemas”.

Los dispositivos IoT funcionan como pasarelas que envían los datos de los sensores a la nube.

Los sensores remotos modernos lo hacen posible al medir con precisión la vibración, temperatura, presión, caudal de aire y estado del equipo. Los datos se transmiten de inmediato a un panel seguro en la nube (accesible desde cualquier lugar), que alerta a los equipos antes de que una falla se manifieste.

Según Eric Schummer, CEO de Senzary, “Las plantas descubren que, una vez que empiezan a recopilar estos datos, las interrupciones a la producción bajan rápidamente. No puedes arreglar lo que no ves, y el IoT elimina por completo ese punto ciego”.

A continuación, te mostramos un ejemplo práctico de cómo funciona el IoT (Internet Of Things), qué beneficios ofrece y cómo empresas de distintos sectores lo están usando para mejorar la confiabilidad, la seguridad y la productividad.

Qué significa la tecnología IoT para la recolección de polvo

Los dispositivos IoT actúan como puntos que envían los datos de los sensores a la nube. Funcionan de manera independiente de los PLC de planta, lo que los hace ideales para sistemas de mantenimiento.

Hoy existen sensores inalámbricos, alimentados por batería, que se instalan fácilmente en:

✅ Motores de ventiladores

- ✅ Rodamientos

- ✅ Válvulas

- ✅ Válvulas rotativas

- ✅ Tanque de aire comprimido

- ✅ Compartimientos del colector

- ✅ Tramos de ductos con riesgo térmico o de chispas

Estos sensores miden vibración, aceleración, temperatura, presión diferencial, humedad y mucho más. Luego, los dispositivos cargan los datos encriptados a través de redes celulares. Esto permite monitorear el desempeño de forma remota y diagnosticar problemas sin subir escaleras ni ingresar a zonas inseguras.

Eric Schummer comenta: “Hoy el hardware es simple. Instalas un sensor, conectas un dispositivo y los datos empiezan a fluir automáticamente. Plantas de cualquier tamaño pueden adoptar mantenimiento predictivo sin rediseñar sus controles”.

Los cuatro beneficios principales del IoT para la recolección de polvo

1 – Conectar equipos que nunca estuvieron conectados

La mayoría de los colectores de polvo solo muestran lecturas locales de presión diferencial o temperatura. Con IoT, incluso los colectores más antiguos pasan a formar parte de un sistema de monitoreo unificado.

La visibilidad remota es especialmente útil para:

- ✔️ Baghouses ubicados en techos

- ✔️ Sistemas distribuidos en plantas muy grandes

- ✔️ Colectores portátiles o móviles

- ✔️ Zonas de alta temperatura o áreas peligrosas

Matt agrega: “Algunos colectores pasan semanas sin que nadie los revise. Con IoT, tienes ojos puestos sobre ellos las 24 horas, todos los días”.

2 – Recolectar automáticamente datos importantísimos

Muchas plantas todavía dependen de registros semanales o anotaciones de los operadores. El IoT elimina esos vacíos al registrar de forma continua:

- ✔️ Presión diferencial continua

- ✔️ Actividad de los ciclos de limpieza

- ✔️ Tendencias de temperatura

- ✔️ Espectros de vibración

- ✔️ Cambios en el desempeño del ventilador

Sin datos confiables no hay línea base, y sin una línea base es imposible planificar el mantenimiento de forma efectiva.

3 – Predecir fallas antes de que se desarrollen

Los filtros, ventiladores, motores y válvulas se desgastan con el tiempo, pero las fallas ocurren mucho más rápido cuando nadie detecta las señales a tiempo.

Los sistemas IoT identifican esas señales, como por ejemplo:

- ✔️ Aumento de vibraciones que indica desgaste de rodamientos

- ✔️ Incremento de la presión diferencial que sugiere obstrucción en los filtros

- ✔️ Picos de temperatura en motores que indican sobrecarga

- ✔️ Ciclos de limpieza anormales por problemas en los diafragmas

El sistema detecta estas desviaciones y alerta de inmediato a las personas correctas.

“La predicción es donde aparece el verdadero valor”, explica Schummer. “Con análisis de vibración, muchas fallas se pueden identificar con semanas de anticipación. Eso les da tiempo a los equipos para programar reparaciones en lugar de reaccionar a la falla improvisadamente”.

4 – Mejorar la confiabilidad y la eficiencia de la planta

Los datos del IoT ayudan a los operadores a optimizar el proceso al analizar el comportamiento de los equipos. Las plantas pueden personalizar alarmas, seguir cambios en la producción y evaluar el impacto de variaciones en las materias primas.

Conocer las causas reales de las condiciones anormales permite reducir pérdidas, bajar el consumo de energía y extender la vida útil de los equipos.

Como dice Matt: “La mejora solo ocurre cuando entiendes lo que realmente está pasando. El IoT te lo explica muy claramente”.

Ejemplos reales de IoT aplicado con éxito

Caso 1: Planta de agregados – Trituradora de roca

Una cantera con tres colectores tenía problemas de caudal desigual y no contaba con una lectura centralizada de la presión diferencial. Los filtros fallaban de forma impredecible, generando interrupciones no planificadas.

✅ Solución:

Los tres colectores se integraron mediante un único controlador IoT que leía la presión diferencial combinada. Se reemplazaron los ciclos de limpieza fijos por limpieza bajo demanda. Además, se agregó un sensor de temperatura en rodamientos con alertas automáticas.

✅ Resultado:

Mejor balance de aire, vida útil de filtros predecible y prácticamente sin interrupciones a la producción.

Caso 2: Operación con polvo metálico peligroso

Una planta de procesamiento de metales manejaba polvos peligrosos que podían generar combustión si cambiaban las condiciones de caudal. El monitoreo manual exponía a los técnicos a riesgos y aun así no detectaba alertas clave.

✅ Solución:

Las notificaciones push del IoT alertaban en tiempo real sobre cortes de energía, caídas de presión y condiciones de caudal inseguras.

✅ Resultado:

Se evitaron incendios, se redujo la exposición del personal y los datos permitieron una operación más segura y confiable.

Caso 3: Silos de almacenamiento de combustibles alternativos

Una planta que manejaba madera y combustibles orgánicos sufría colapsos frecuentes de filtros por presiones elevadas desconocidas. En ocasiones, el sistema de limpieza quedaba desconectado después del mantenimiento, empeorando las fallas.

✅ Solución:

Un sistema completo de control IoT para el colector, con tendencias de temperatura y presión diferencial, reveló el comportamiento del material y alertó de inmediato cuando el aire comprimido quedaba desconectado.

✅ Resultado:

Aumentó la vida útil de los filtros, las fallas se detectaron a tiempo y los operadores entendieron cómo ciertos combustibles afectaban al baghouse.

Conclusión

El mantenimiento predictivo mediante IoT ya no es opcional… es una ventaja competitiva.

Al evaluar una solución IoT, preguntate:

⁉️ ¿Se conectará fácilmente a tu equipo?

- ⁉️ ¿Recolectará los datos que realmente necesitás?

- ⁉️ ¿Predicirá fallas con anticipación?

- ⁉️ ¿Ayudará a mejorar el desempeño de la planta a largo plazo?

- ⁉️ ¿Será compatible con distintas marcas de sensores y equipos?

Como dice Matt: “La recolección de polvo ya no tiene por qué ser reactiva. Con IoT, te adelantas a los problemas en lugar de correr detrás de ellos”.

El IoT ya está entre nosotros. Las plantas que lo adoptan están reduciendo las interrupciones a la producción, extendiendo la vida útil de los equipos y logrando una visibilidad de sus operaciones como nunca antes.

Si se implementa correctamente, el mantenimiento predictivo pasa a ser la norma (no la excepción) y los colectores de polvo se vuelven mucho más confiables, eficientes y seguros.

✅ Motores de ventiladores

✅ Motores de ventiladores ⁉️ ¿Se conectará fácilmente a tu equipo?

⁉️ ¿Se conectará fácilmente a tu equipo?