Dust collectors can discharge collected material in several different ways, depending on the process, dust characteristics, safety requirements, and whether explosion isolation is needed. The most common dust collector discharge systems include rotary airlocks (rotary valves), double dump valves, screw conveyors, bulk bag or super sack discharge, slide gates and knife gates, and dense phase or pneumatic conveying discharge. But there is yet another option: drum and bin collection systems. Today, we will expand on this very simple, cost-effective, and commonly used method.

A Simple and Reliable Approach to Explosion Isolation

The Raptor Drum Explosion Tested Drum Kit is designed to act as an extension of the dust collector while providing passive explosion isolation. Its design is intentionally simple. It does not require wiring, motors, starters, chains, wipers, or routine mechanical maintenance. Because there are no moving parts, reliability is increased and long-term operating costs are reduced.

Understanding the Role of the Drum Kit in Explosion Protection

It is important to understand how drum kits fit into an overall combustible dust protection strategy. A drum kit is not designed to contain the full pressure of a deflagration on its own. Instead, it must be used alongside properly designed explosion mitigation equipment such as explosion vents or suppression systems. These systems are responsible for relieving or controlling the pressure and flame effects generated during a deflagration event. The drum kit is intended to withstand the reduced pressure that remains after those protections have done their job.

In the event of a dust explosion, the Raptor Drum is engineered to withstand internal pressures of up to 7 psi. It prevents flame from escaping through the dust collector discharge, helping stop an explosion from propagating downstream. This makes it a cost-effective alternative to rotary airlocks, explosion isolation valves, and other discharge devices that are used to meet NFPA 660 requirements for ST-1 combustible dusts.

Design Considerations for Proper Installation

When installing a drum kit, system design considerations are critical. The added volume of the drum and the additional height below the dust collector must be accounted for when sizing explosion vents or suppression systems. Flame stretching effects and reduced pressure limits should be evaluated using the guidance provided in NFPA 660. Proper design ensures the drum kit performs as intended during both normal operation and an abnormal event.

Day-to-day Operation of a Drum Kit

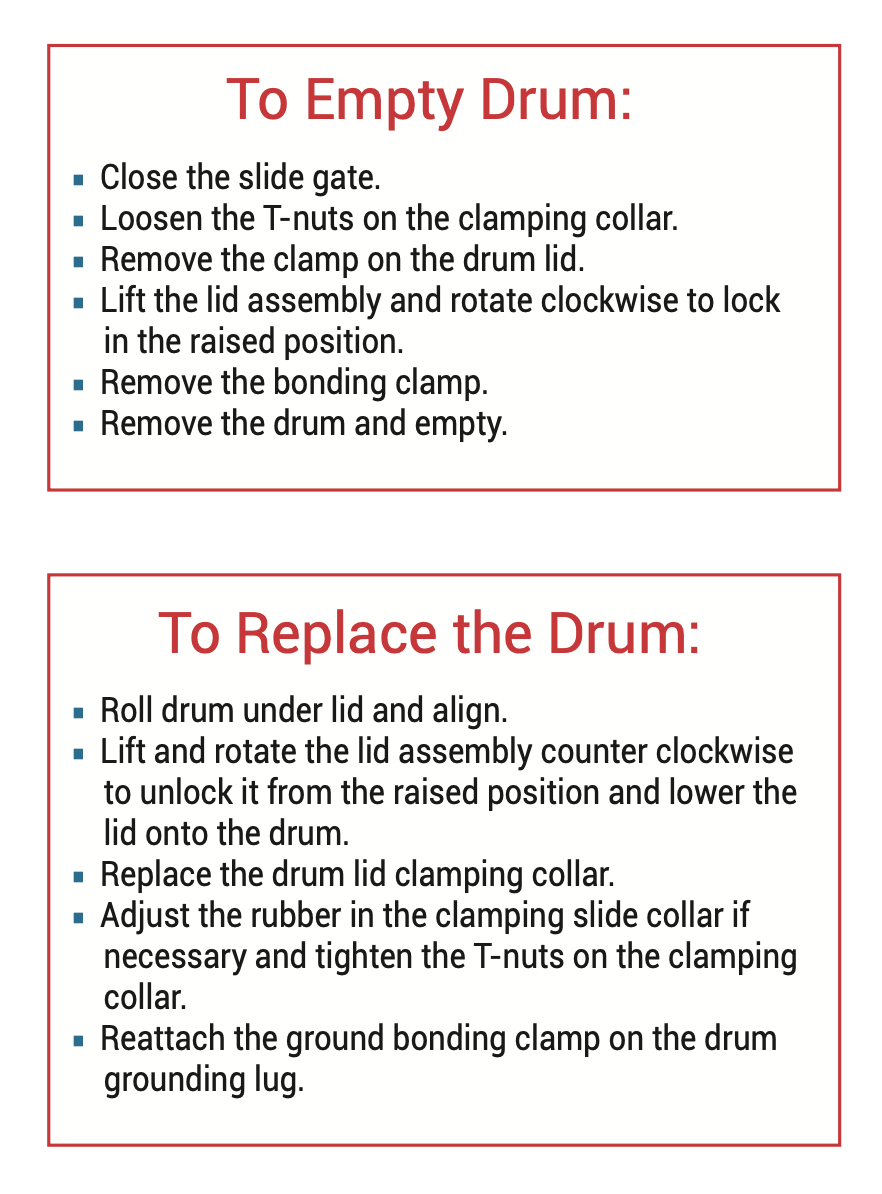

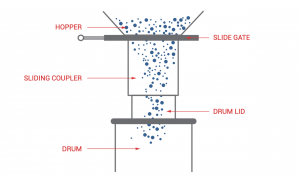

From an operational standpoint, the Raptor Drum system is designed to be straightforward and ergonomic. A hydraulic drum lift is used to raise a standard 55-gallon drum into position beneath the collector. Before operating the dust collector, the drum must be securely clamped to the lid using the supplied locking mechanism to ensure a tight seal. The slide gate must be open during normal operation, the locking collar must be properly tightened, and the drum lid must be fully clamped to prevent leaks.

Safety Practices During Operation

Compatibility and Retrofit Options

A standard Raptor Drum kit includes the slide gate, sliding coupler, drum lid with handles, drum lid clamp, bonding wire, drum, and drum dolly. While the standard drum does not include handles, custom drum options may be available upon request. For proper fit and performance, collar overlap dimensions must be followed carefully during installation.

Drum Kit Installation Instructions

Raptor Drum Frequently Asked Questions

— Can the Raptor Drum be used with other dust collectors?

Yes. The Raptor Drum can be used with any dust collector that is designed to discharge into a drum underneath the unit.

— Can the Raptor Drum be retrofitted to existing collectors?

Yes. The Raptor Drum can replace non NFPA compliant drums, rotary airlocks, and flex hose arrangements on both new and existing dust collectors.

— What is included as part of the Raptor Drum?

The standard kit includes a slide gate, sliding coupler, drum lid with handles, drum lid clamp, bonding wire, and drum.

— What discharge sizes are available?

Raptor Drum kits are available in 10, 12, 14, 16, and 18 inch discharge sizes.

— Are there any handles on the drum?

The standard drum does not include handles. Custom drum options with handles may be available upon request.

— What is the maximum KST the Raptor Drum can handle?

The Raptor Drum can be used with ST 1 class dusts up to 185 KST.

— How much should the collar overlap the slide gate of the Raptor Drum?

The collar should overlap the drum cover by 2 3/8 inches.

— How much should the collar overlap the lid of the Raptor Drum?

The collar should overlap the drum cover by 2 7/8 inches.

(If you have any additional question, please click here to text us!)

When selected, designed, and installed correctly, drum kits like the Raptor Drum provide a practical and reliable way to collect dust while supporting explosion isolation goals. They simplify maintenance, improve safety, and help facilities meet combustible dust protection requirements without adding unnecessary complexity to the dust collection system.