¿Polvo? ¿Qué polvo? ¡Los filtros P84 lo hicieron desaparecer!

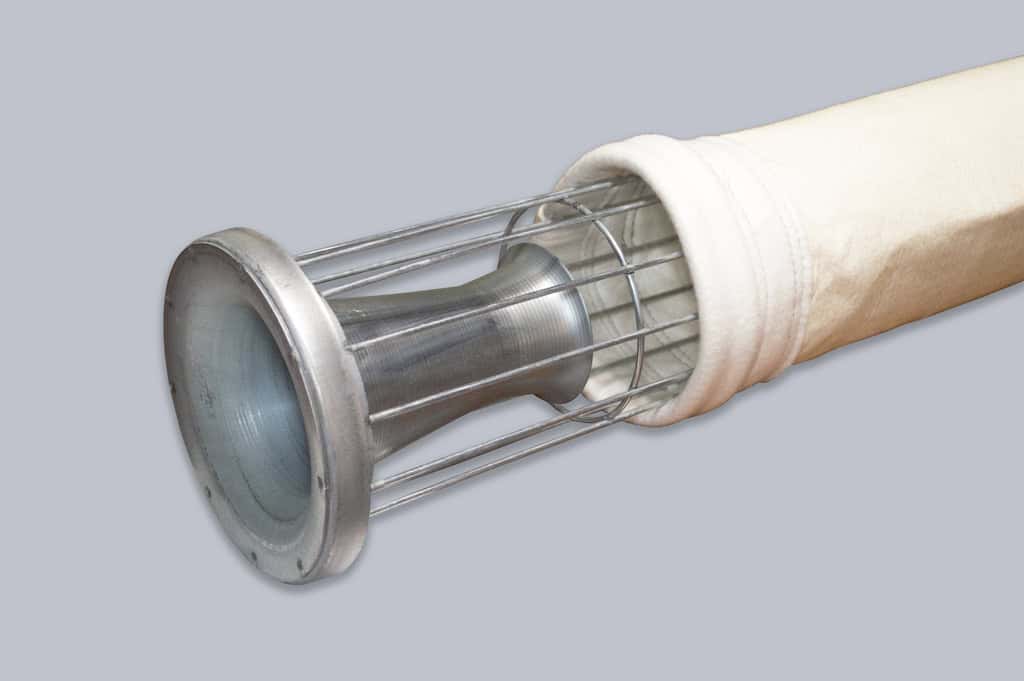

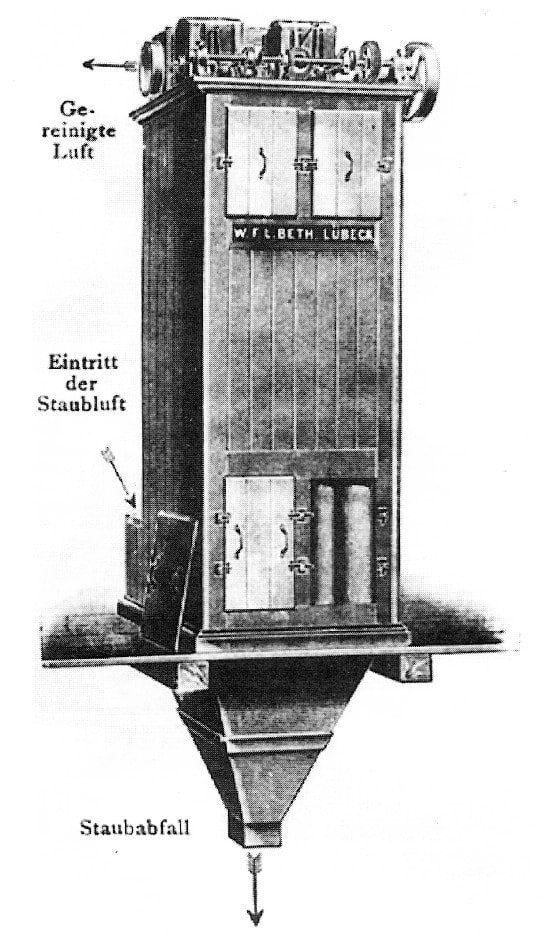

Known for their exceptional durability and high-performance filtration properties, P84 filters are designed to work on extreme conditions across industries like cement, incineration, power generation, and more. Let’s understand why P84 filters are a preferred option for many industrial processes and how they deliver consistent, cost-effective results.

Unique Characteristics of P84 Filters

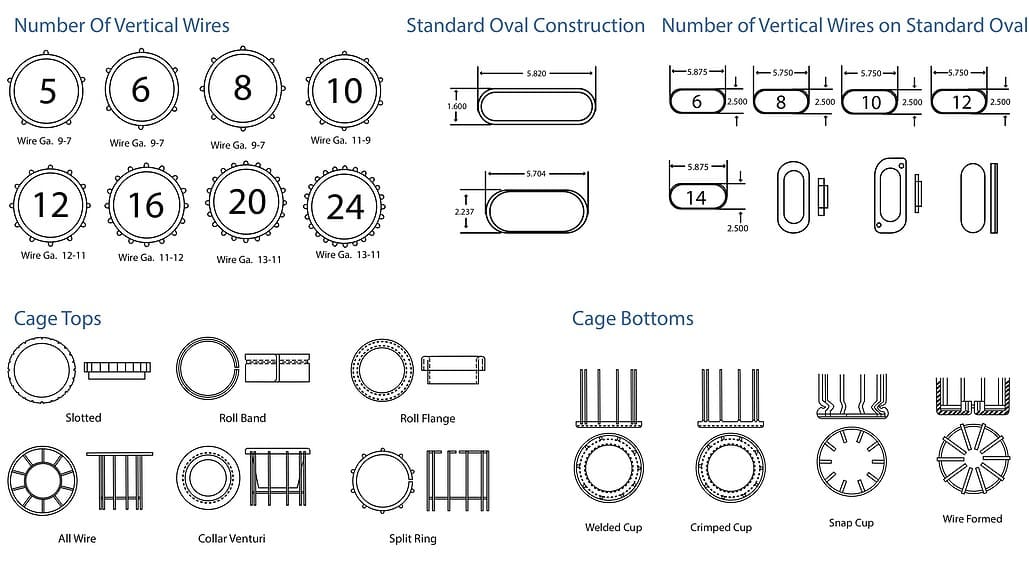

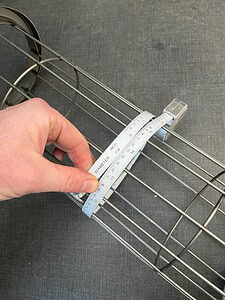

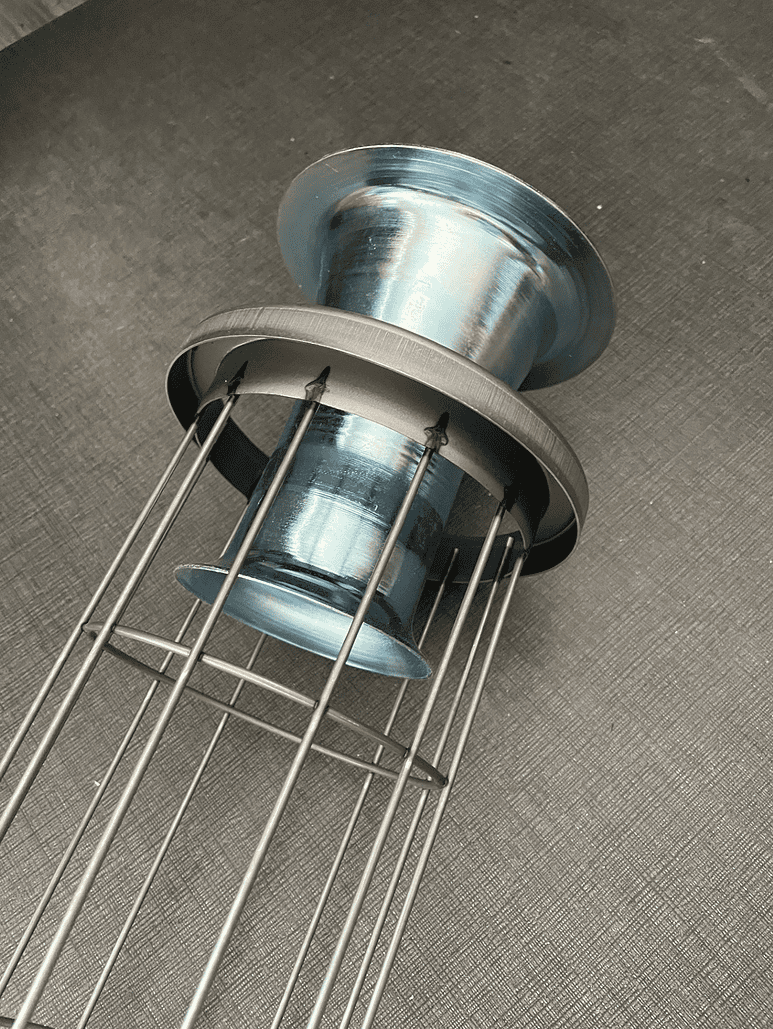

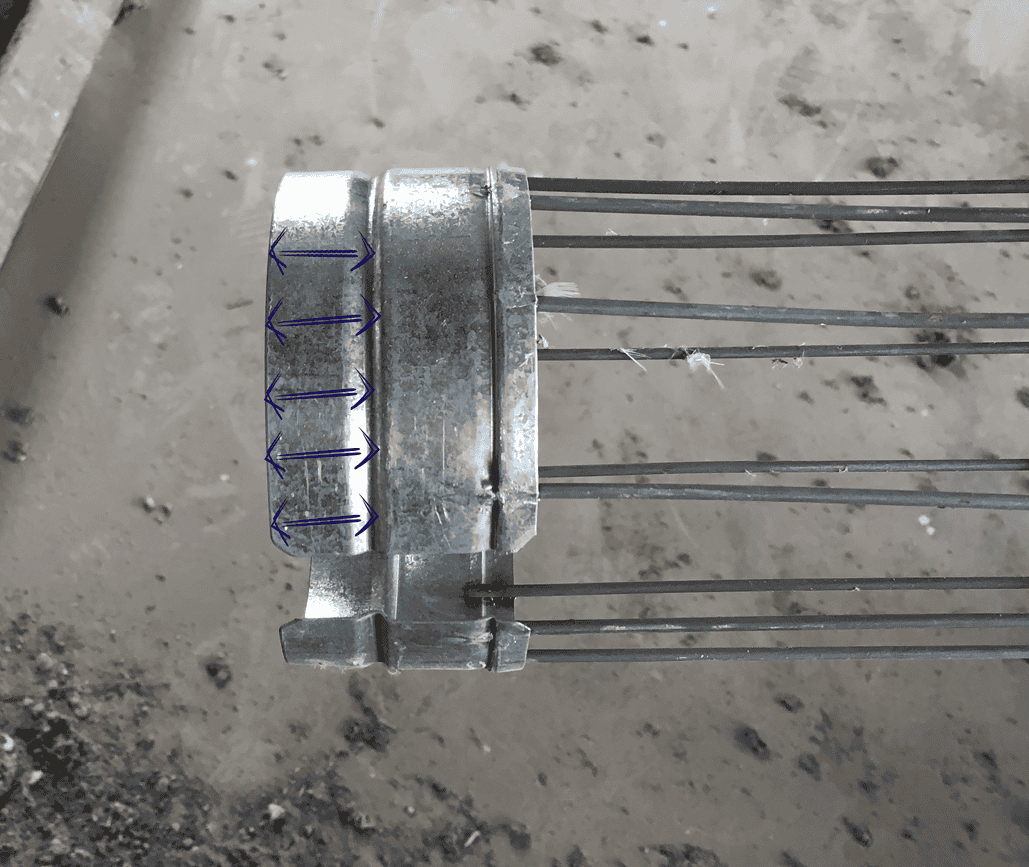

P84 fibers are needled into high-quality felts, suitable for pulse jet baghouses, and can also be blended with other fibers like PTFE, PPS, PAN, and PES to meet specific operational requirements. P84 filters are engineered with tri-lobal fibers that offer:

- — High surface area: The irregular shape creates 30–90% more surface area compared to round or oval fibers, enhancing dust collection and cake release.

- — Temperature resilience: Continuous operation up to 500°F, with short-term peaks of 500°F without fabric degradation.

- — Chemical resistance: Effective against acids, alkalines, and hydrolysis, making them suitable for aggressive environments.

- — Non-flammability

Applications Across Industries

P84 filters have become a go-to choice for numerous industries, thanks to their versatility and reliability in extreme conditions:

⦿ Cement Plants: Ideal for kilns with fluctuating temperatures and dust loads. Withstands alkaline dust and high humidity in alumina calciners. Provides high filtration efficiency even under heavy dust loads (>500 g/Nm³). Compatible with varying pH levels (2–12), ensuring performance with secondary fuels. (Read here our most recent case studies in the Cement and Aggregates application)

⦿ Waste Incineration Facilities: Handles aggressive chemical environments during scrubber or cooling system downtimes.Supports dust cake formation, capturing fine particles and dioxins, neutralizing acidic flue gases using lime powder and retaining heavy metals with activated carbon. Enables cost-effective bag disposal through incineration, avoiding hazardous waste treatment fees.

⦿ Power Generation: Performs well in coal-fired boilers, resistant to SO₂ and oxygen. Suitable for biomass-fired plants with varying operating loads and flue gas compositions. Operates efficiently in wet scrubbing systems and semi-dry absorption setups.

⦿ Metallurgical and Processing Industries: Resilient against sparks, abrasive dust, and extreme temperatures in lime kilns and electric arc furnaces. Prevents dust penetration during fluctuating airflow rates or A/C ratios. (Read here our most recent case studies in the Metalworking and Foudries application)

-

⦿ Asphalt Production: Delivers reliable filtration in asphalt and hot mix plants. (Read here our most recent case studies in the Asphalt application)

Advantages of P84 Filters

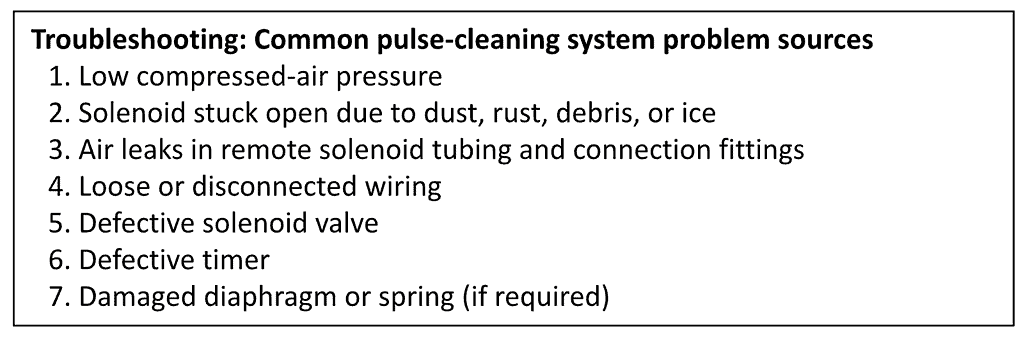

- Low Maintenance Costs: Long service life minimizes bag replacements. Durable needle felts withstand cleaning pressures up to 6 bar without delamination.

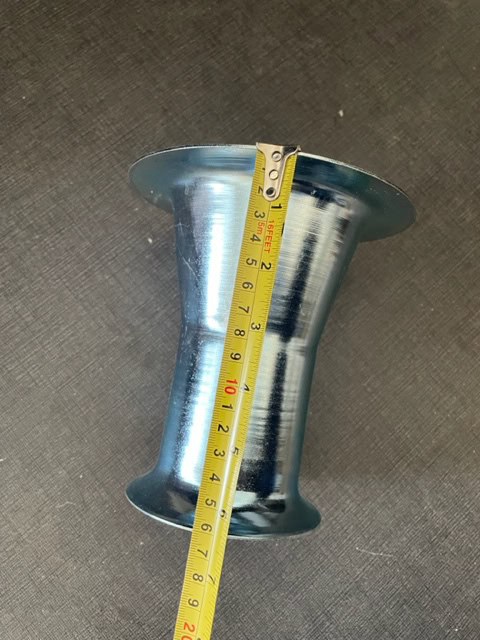

- Cost-Effective Design: Standard cages are sufficient; no need for costly double-wire cages. Lower energy consumption due to reduced pressure drops and efficient cleaning cycles.

- Environmental Safety: Minimal toxic emissions during incineration of used bags. Meets stringent emission standards, ensuring regulatory compliance.

- High Flexibility: Performs across a wide range of flue gas compositions, temperatures, and dust loads. Adapts to varying operating conditions in industries using secondary fuels.

Operational Guidelines for Filters P84

Temperature Management

In general, the life cycle of any synthetic material is reduced with rising temperatures. Every 50° F the speed of the chemical reaction doubles! This increase is lower for P84 but in principle also valid for P84. Therefore the continuous operating temperature in conjunction with the flue gas parameters has a decisive influence on the lifetime of filter bags. Special attention has to be taken into consideration in case of the occurrence of high operating temperatures together with oxidizing agents like O2 and NO2. Most of all NO2 is very aggressive for any kind of synthetic fiber, while NO has no influence on the life cycle at all.

Continuous operation should stay within the recommended temperature range to maximize lifespan:

- 235°–320°F: 60–72 months

- 320°–355°F: 24–48 months

- 355°–392°F: 12–36 months

Short term peaks of 500° F do not cause problems for P84, however longer periods around 500 °F may lead to fabric shrinkage in case the heat treatment of the needle felt in production has not been made in a proper way. Short-term peaks are defined with duration of the app. from 5 to 10 minutes. Depending on the continuous operation temperature and other flue gas components, the total peak temperature duration can be limited from 100 to app. 400 hours per year for achieving the requested bag life.

Moisture and Dew Point

Operation at or below the acid –and water– dew point should be avoided at any time. Heating baghouses during shutdowns can mitigate moisture-related risks.

Condensation as well as operation close to the dew point may result in problems in case the pH of the dust is extremely acidic (pH < 3) or alkaline (pH > 11). In that case, heating of the bag house during shutdowns is recommended. As long as moisture is excluded, dry acidic or dry alkaline dust does not attack the fiber. High moisture contents (> 35 % vol) have to be taken into consideration as well.

Bag Disposal at the End of Filter Life

In comparison with PTFE materials or glass products, P84 shows very low toxic gas generation when being burnt. Instead of expensive bag disposal at hazardous waste treatment plants, P84 bags can be burnt in the incinerators of end users.

Conclusión

Los tejidos P84 se utilizan en aplicaciones de alta temperatura

If you’re considering upgrading your dust collection system or need help selecting the right filter for your specific application, reach out to us. It is always better to double check with a dust collection expert before making the change to a different filter fabric.

⦿ Cement Plants:

⦿ Cement Plants:  ⦿ Waste Incineration Facilities:

⦿ Waste Incineration Facilities:  ⦿ Power Generation:

⦿ Power Generation:  ⦿ Metallurgical and Processing Industries:

⦿ Metallurgical and Processing Industries:

Other dusts are inherently toxic and should be avoided as much as possible due to their severe health risks:

Other dusts are inherently toxic and should be avoided as much as possible due to their severe health risks: