In most facilities, dust collectors discharge their air outside the building. But in certain situations, bringing that air back inside can be a smart move, as long as it’s done correctly and safely. Recirculating air isn’t for every plant, but when it’s appropriate, it can save money, simplify regulatory challenges, and prevent headaches with neighbors.

As Dominick Dal Santo, Dust Collection Expert at Baghouse.com, said: “Recirculating air can be a big win, but only if the system is engineered with safety front and center.”

Below, we break down the three biggest reasons facilities choose to recirculate air, followed by the safety considerations every engineer should understand.

1— Significant Savings on Heating and Cooling

For many plants, energy is one of the largest operating costs. When conditioned air is continuously pulled out of the building through the dust collector and replaced with cold or hot outside air, HVAC systems work overtime.

By working to maximize the efficiency of the entire process, plant operators can at times drastically reduce the amount of energy needed to operate the system

By recirculating air from the dust collector (especially from a large system) you can save thousands. For example, recirculating air from a 10,000 CFM collector, heating it to 70°F when outdoor air is 10°F, can save about $1,600 per month.

Scott Omann, Aftermarket Division Manager at Baghouse.com, puts it simply: “Why pay to heat or cool air just to immediately throw it outside? Recirculation lets you keep what you’ve already paid for.”

High-ceiling facilities benefit even more, since hot air naturally rises. Many plants draw air from the ceiling level and return it near the floor, improving comfort and reducing heating costs.

2— Avoiding the Regulatory Burdens of Outdoor Emissions

Emissions permitting through state agencies or the EPA can involve applications, stack testing, and long review timelines. Some facilities reduce or avoid these requirements by not emitting anything outside at all.

When air is recirculated indoors, oversight often shifts from environmental regulations to OSHA indoor air quality rules. But that doesn’t mean plants get a free pass.

OSHA may require: testing indoor air quality, establishing an 8-hour time-weighted average (TWA) exposure and proving contaminant levels stay below required thresholds. Some jurisdictions still require a permit even if the air stays inside, so local rules must be reviewed carefully.

Dominick notes: “Recirculation can simplify the emissions side, but OSHA fills that gap. It doesn’t mean less responsibility, it’s just a different kind of responsibility.”

3— Reducing Complaints From Nearby Neighbors

Even minor emissions can lead to conflicts with neighbors, public complaints, or media attention. Recirculating air keeps all dust inside the facility, helping plants avoid odor complaints, visible emissions concerns, accusations of environmental harm and legal or regulatory escalation. For plants located close to residential or commercial areas, this can be a major advantage.

However... RECIRCULATION REQUIRES CAUTION

Despite the benefits, plants must understand the engineering risks before returning filtered air indoors.

Combustible Dust Requirements

NFPA standards such as NFPA 654 set strict rules for dust collectors handling combustible dusts. Some materials (like aluminum dust) may only be safely handled by systems located outdoors and exhausted into the atmosphere.

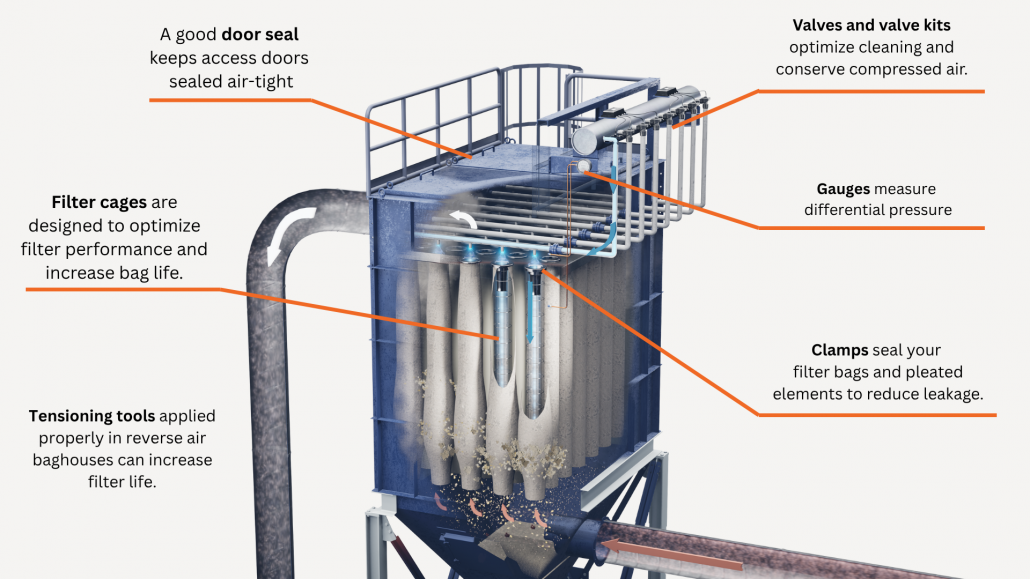

Recirculation may require detailed hazard analysis, explosion protection upgrades and additional suppression or isolation devices. Each application must be evaluated individually.

Stricter OSHA Indoor Air Limits

OSHA indoor air quality limits can be far stricter than outdoor emissions standards.

For example:

- ✔️ General nuisance dust (<10 microns): 5 mg/m³

- ✔️ Crystalline silica: 05 mg/m³ (100x more strict than nuisance dust)

- ✔️ Metals or chemical dusts: Often extremely low permissible limits

Any hazardous material requires:

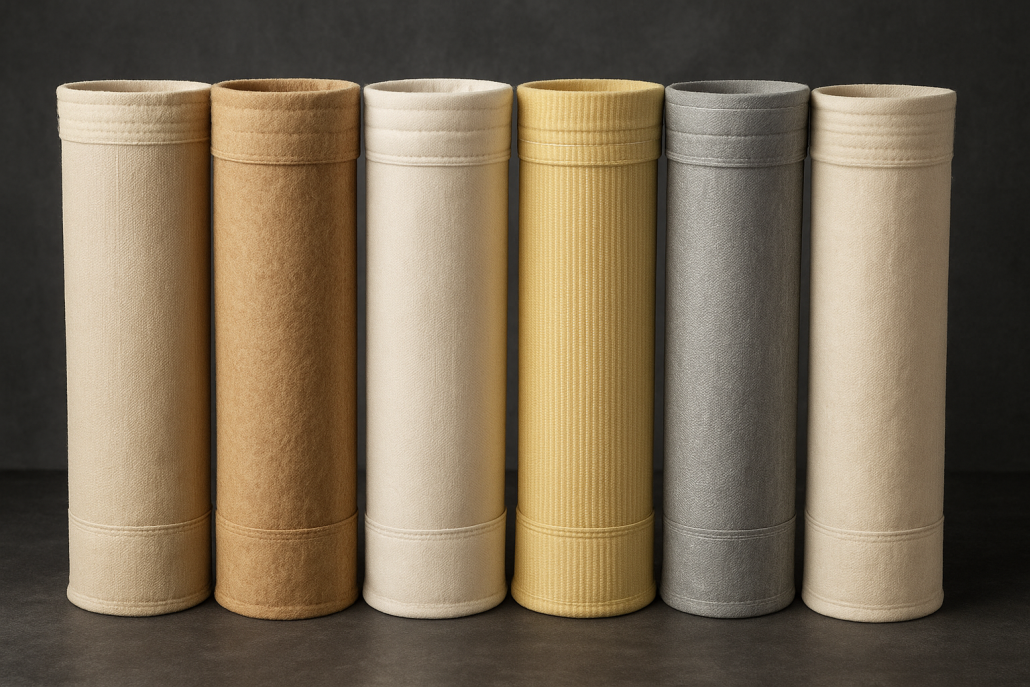

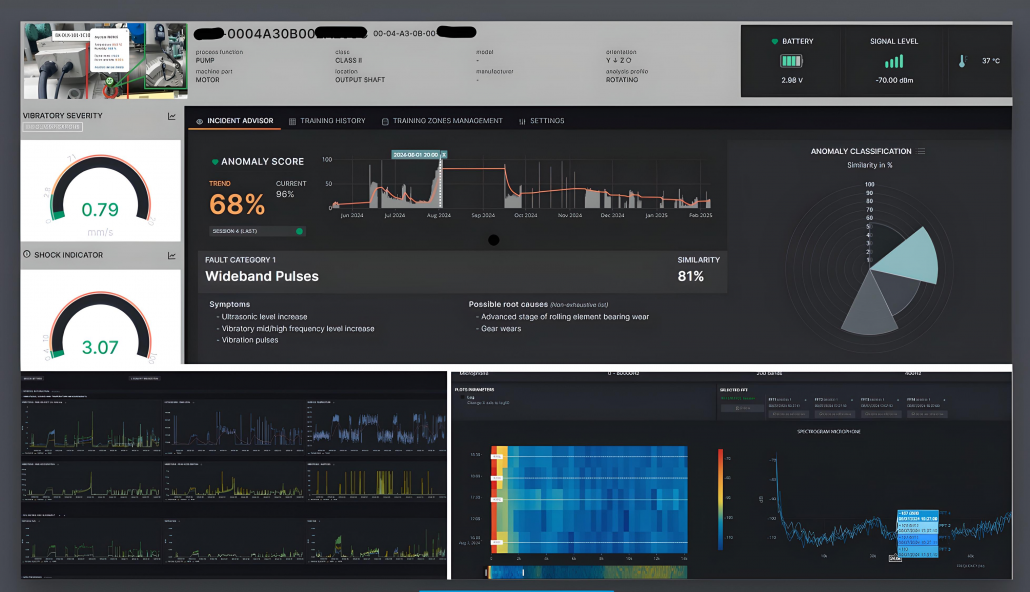

- ✔️ Continuous monitoring, such as triboelectric bag leak detectors

- ✔️ Secondary HEPA filters

- ✔️ A well-documented air quality program

If you’re considering recirculation for your facility, talk with a dust collection expert. A proper evaluation ensures the system is safe, compliant, and optimized for performance.

How to Return the Air Back Into the Facility?

To keep the system balanced and save energy, the return air should ideally be sent back to the same areas where it was originally exhausted. A common design mistake is exhausting air from one room and supplying it to a different area, which can create unwanted negative pressure in one space and positive pressure in another.

A properly designed recirculation system does more than reduce energy costs, it can also improve worker comfort. For example, in a facility with multiple welding stations, the system may use a single main duct with adjustable diffusers at each workstation. These diffusers allow workers to control the airflow much like a personal fan, directing air toward or away from their work area as needed.

There are two main ways to configure return air systems.

The first is a general ventilation system with zone return, commonly used in colder climates. This approach captures warm air near the ceiling and redistributes it back into the work area, helping recover heat. It is also useful when the process does not allow for source capture hoods. The drawback is that general ventilation systems require much higher airflow, which means larger fans and filters, higher equipment costs, and increased operating expenses.

The second option is a source capture system with zone return. In this setup, hoods are installed directly at each workstation to capture contaminants at the source. This design is more efficient because it requires lower airflow, smaller fans, and fewer filters. However, it is only suitable for processes that remain in fixed locations and cannot be used for mobile or changing operations.

At the end of the day, recirculating dust collector air is one of those decisions that looks simple on paper but really comes down to the details. When it’s engineered correctly, it can lower energy costs, improve comfort, and remove a lot of friction around emissions and neighbor concerns. When it’s rushed or treated as a shortcut, it can create serious safety and compliance problems. That’s why there’s no one-size-fits-all answer. Every material, process, and facility layout matters. If you’re even thinking about recirculation, it’s worth having a real conversation with someone who’s designed these systems before—someone who can walk your plant, ask the hard questions, and help you decide if recirculation truly makes sense for your operation.