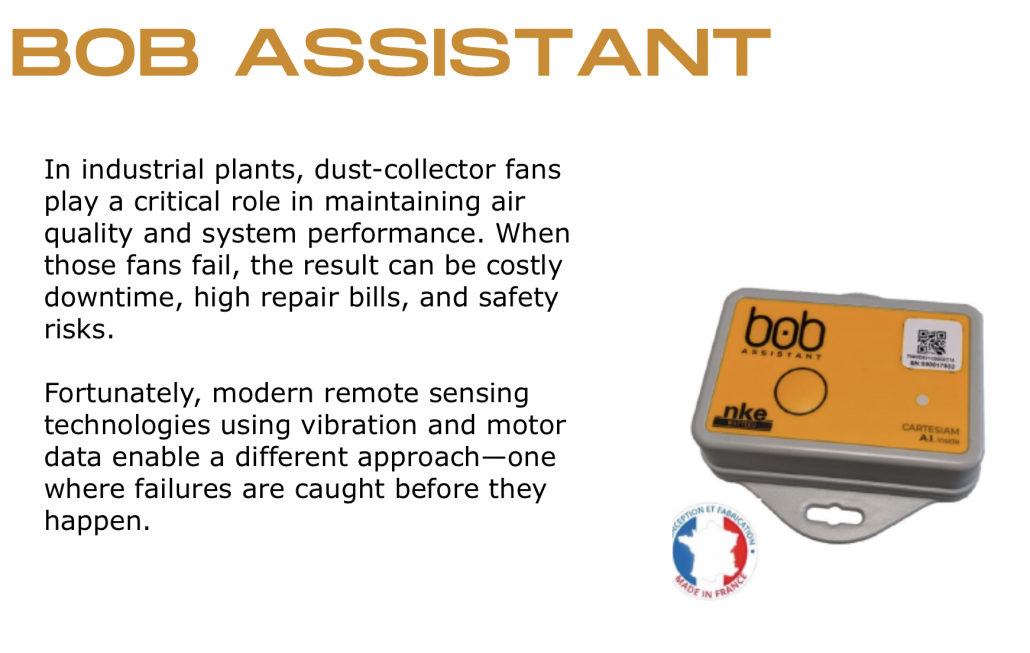

Usar datos de vibración del motor para prevenir fallas en ventiladores de colectores de polvo ya no es un proceso complicado ni costoso, gracias a la tecnología moderna de sensores IoT. El monitoreo remoto permite detectar pequeños cambios en el comportamiento del ventilador mucho antes de que se conviertan en fallas graves. Matt Coughlin, dueño de Baghouse.com nos cuenta: “Antes dependíamos de la intuición y de revisiones periódicas. Ahora podemos ver en tiempo real qué está pasando con un ventilador incluso antes de que los operadores noten algo. Esto cambia por completo la forma en que trabajan los equipos de mantenimiento.” Con sensores fáciles de instalar y transmisión continua de datos, las plantas pueden adelantarse a los problemas en lugar de reaccionar cuando ya es demasiado tarde.

¿Cómo funcionan los sensores remotos?

En un sistema de recolección de polvo, esto significa que puedes monitorear motores de ventiladores, sopladores y equipos relacionados las 24 horas del día. En lugar de depender de intervalos fijos de mantenimiento o esperar a que un ventilador muestre señales claras o ruidosas de falla, el monitoreo remoto con IoT te ayuda a detectar desgaste de rodamientos, desbalance o componentes sueltos días o incluso semanas antes de que ocurra un problema serio. Esto evita fallas catastróficas, reduce emergencias y mantiene la producción funcionando sin sorpresas. Estudios del sector siguen demostrando que el monitoreo basado en vibraciones es una de las formas más efectivas de reducir interrupciones no planificadas y costos de mantenimiento. Matt Coughlin lo resume así: “Te sorprendería saber cuántos desastres empiezan con una pequeña vibración imperceptible. Cuando los sensores la detectan a tiempo, es como recibir una advertencia antes de que el problema siquiera exista.”

Mantenimiento proactivo

Más allá de prevenir fallas, este método brinda información operativa real y útil. Los análisis integrados convierten las señales de vibración y temperatura en información clara sobre el estado del equipo, la vida útil restante y el mejor momento para realizar mantenimiento. El mantenimiento finalmente puede programarse de forma proactiva, justo cuando hace falta, y no solo porque lo diga el calendario. Esto se traduce en menos reemplazos innecesarios de piezas, menos interrupciones inesperadas y una vida mucho más larga para ventiladores, motores y todo el sistema de recolección de polvo.

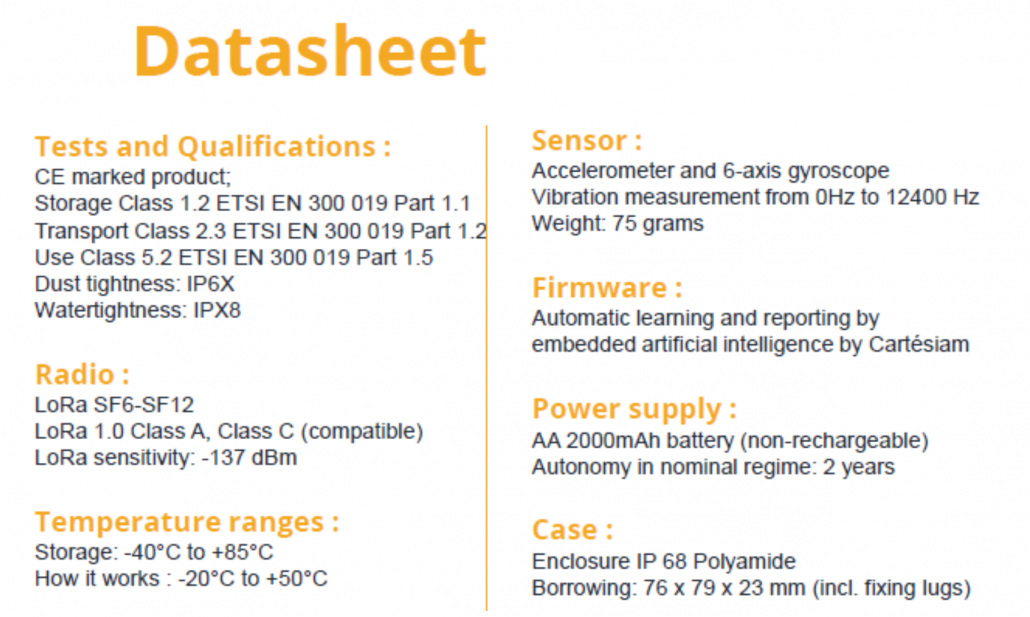

Implementar sensores IoT remotos hoy es más fácil que nunca. Estos sensores inalámbricos alimentados por batería y con protocolos de largo alcance, eliminan la necesidad de cableado complejo. La instalación muchas veces se puede hacer en minutos y con mínima interrupción… ¡incluso con el equipo en funcionamiento! Los datos se transmiten a través de portales hacia un software seguro en la nube, accesibles desde computadoras o dispositivos móviles, lo que brinda a los equipos de mantenimiento visibilidad en tiempo real desde cualquier lugar.

Si manejas sistemas de recolección de polvo, mantenimiento de planta u operaciones industriales, integrar monitoreo IoT basado en vibración en tu estrategia de mantenimiento ofrece un camino práctico hacia una operación más segura, confiable y rentable.