En este artículo hemos compilado las preguntas más comunes que escuchamos de gerentes de planta, líderes de operaciones, equipos de mantenimiento y profesionales de EHS sobre mantenimiento predictivo y cumplimiento de regulaciones para emisiones. Aquí vas a encontrar sus preocupaciones cotidianas, y la explicación de cómo las herramientas IoT modernas están transformando el control de polvo, reduciendo riesgos y fortaleciendo el cumplimiento normativo en instalaciones industriales.

— "¿Qué es el mantenimiento predictivo y cómo nos ayudan los sensores remotos?"

El mantenimiento predictivo consiste en usar datos para detectar señales tempranas de fallas y actuar antes de que el equipo se averíe. En colectores, el IoT permite la recopilación continua y automática de señales como vibración, corriente del motor, temperatura de rodamientos, presión diferencial a través de los filtros, conteo de pulsos y flujo de aire. Estos datos se envían a una plataforma central donde el análisis de umbrales identifica tendencias y anomalías. En lugar de inspecciones programadas o esperar a que suene una alarma, recibes notificaciones cuando un rodamiento empieza a desalinearse, un motor consume más corriente, los filtros comienzan a obstruirse o los ciclos de limpieza se vuelven anormales. Esta visibilidad temprana reduce reparaciones de emergencia, evita interrupciones no programadas y extiende la vida útil de los componentes.

— ¿Qué sensores y mediciones son más útiles para el mantenimiento predictivo en colectores?

Las mediciones clave incluyen la presión diferencial (plenum limpio vs. sucio), corriente y temperatura del motor del ventilador, vibración (acelerómetros triaxiales), contadores de válvulas de pulso y presión, flujo de aire o presión estática en puntos críticos, y sensores de partículas para confirmar el desempeño de la filtración. Combinar varias señales mejora la precisión. Por ejemplo, un aumento de la presión diferencial junto con ciclos de pulso más frecuentes y un ligero incremento en la carga del motor del ventilador es una advertencia mucho más clara que cualquiera de esas señales por separado.

— ¿Cómo ayuda el IoT con el cumplimiento de emisiones?

El IoT proporciona registros continuos y con marcas de tiempo de parámetros relacionados con emisiones: conteos o masa de partículas (PM2.5 / PM10), presión diferencial a través de los filtros, conteos de pulsos y desempeño de limpieza, temperaturas de entrada y salida, y alarmas. Estos datos pueden archivarse para autoridades regulatorias, usarse para demostrar tendencias y acciones correctivas, y vincularse a los procedimientos operativos del sitio. Cuando ocurre una desviación o un accidente, el sistema puede generar alertas inmediatas y producir un registro auditable que muestre qué pasó y qué acciones correctivas se tomaron.

— ¿Los sistemas IoT pueden instalarse en colectores antiguos o se necesita un reemplazo completo?

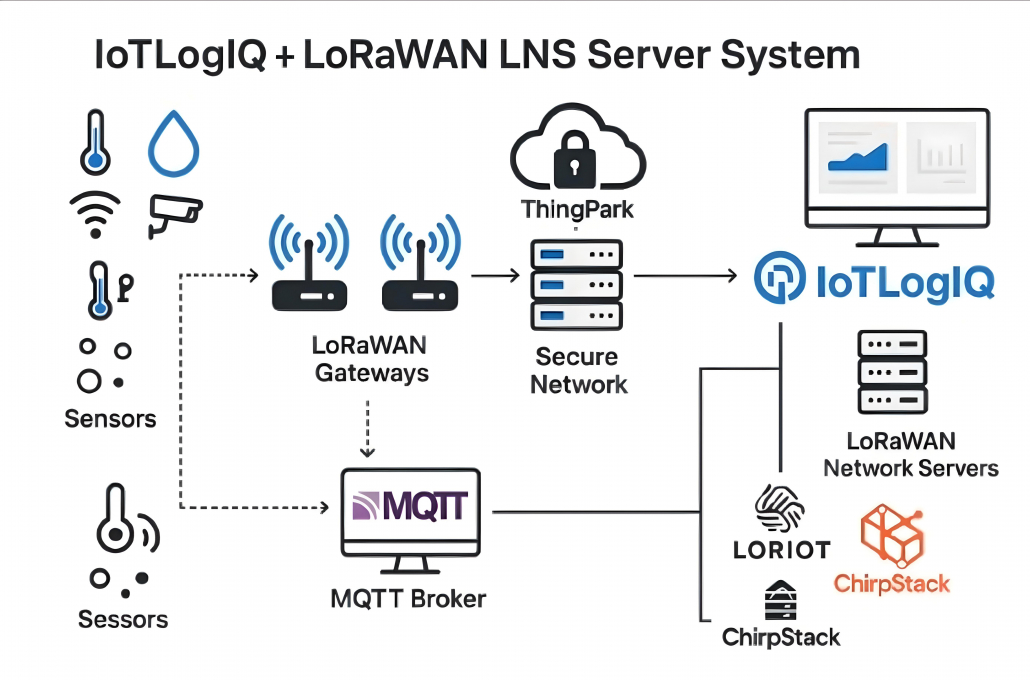

La mayoría de las soluciones IoT están diseñadas para adaptarse a cualquier sistema. Sensores inalámbricos alimentados por batería y convertidores de protocolo permiten agregar monitoreo sin modificar controles ni instalar cableado extenso. Salidas Modbus o analógicas de equipos antiguos pueden digitalizarse, y gateways LoRaWAN o celulares envían los datos a la nube. En muchos casos, los sistemas mecánicos del colector permanecen sin cambios, mientras que la visibilidad y el análisis se agregan rápidamente.

— ¿Qué tan rápido puede implementarse una prueba piloto de mantenimiento predictivo con IoT y mostrar resultados?

Un piloto enfocado —instrumentando de 1 a 3 colectores críticos— puede instalarse y configurarse en pocos días. Los primeros beneficios suelen venir del análisis de presión diferencial, carga del motor del ventilador y conteos de pulso. En cuestión de semanas, pueden verse tendencias claras que indiquen sobrelimpieza, filtros con fugas o un rodamiento del ventilador en mal estado. Gracias a que el hardware es “plug-and-play”, el tiempo para obtener información útil es mucho menor que en proyectos SCADA tradicionales.

— ¿Cuáles son los beneficios económicos y los factores de retorno de inversión?

El IoT reduce reparaciones de emergencia, extiende la vida de filtros y rodamientos, disminuye interrupciones no programadas y reduce la mano de obra dedicada a inspecciones manuales. Los ahorros provienen de menos compras urgentes de repuestos, menor pérdida de producción y menor consumo de energía (al evitar sobrelimpieza o ventiladores operando de forma ineficiente). En muchas plantas, el retorno de inversión de una implementación básica de sensores es de 6 a 18 meses, dependiendo del equipo y los costos de falla.

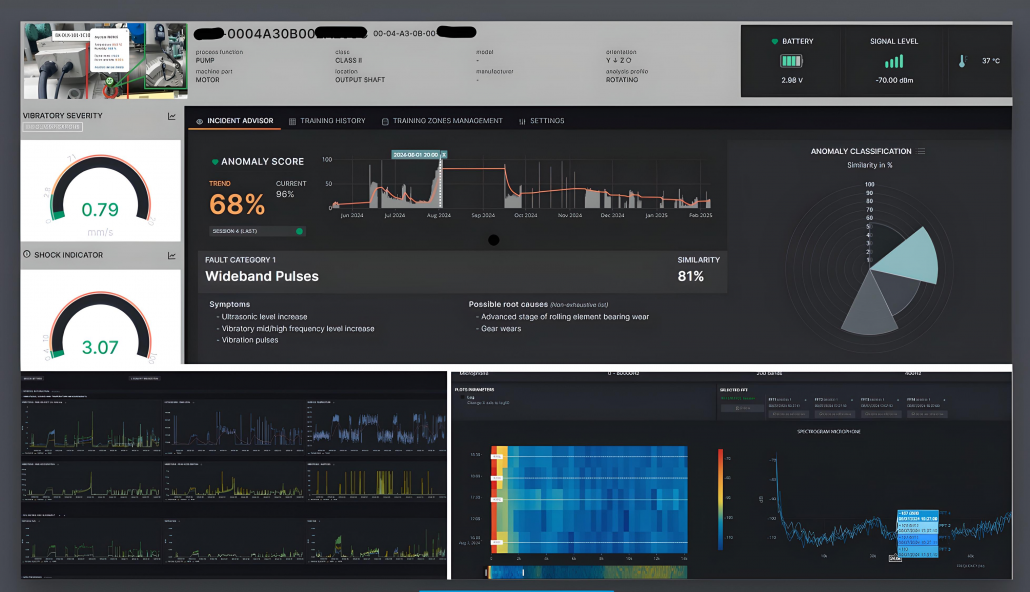

— ¿Cómo convierten las plataformas de software y la IA los datos en acciones concretas?

Los datos se envían a una plataforma donde se aprende el comportamiento “normal” del sistema. Los análisis realizan estudios de tendencia, comparan señales y aplican reglas o aprendizaje automático para identificar modos de falla probables: degradación de rodamientos, desbalance, cegado de filtros, fallas de solenoides o bloqueos en ductos. Las alertas se envían a las personas correctas con acciones sugeridas (por ejemplo, revisar rodamiento del ventilador, programar reemplazo, inspeccionar banco de válvulas de pulso). Las plataformas también ofrecen tableros, reportes históricos y registros exportables para notificar a las autoridades, si es necesario.

— ¿Cómo sé si mis datos están seguros?

Las implementaciones modernas priorizan la seguridad. Normalmente se usan conexiones solo de salida desde los gateways locales hacia la nube, cifrado TLS, certificados de dispositivos y control de acceso por roles. El IoT puede subirse a la nube, de forma híbrida o completamente en sitio para cumplir requisitos de TI o regulatorios. En pruebas piloto, muchas plantas usan gateways independientes o conexiones celulares para demostrar valor sin procesos complejos de TI.

— Cuéntame algunos casos de buenos resultados con sensores remotos

Caso A — Planta de cemento: predicción de falla en rodamientos del ventilador

Una planta sufría fallas intermitentes de rodamientos que causaban interrupciones de fin de semana y compras urgentes muy costosas. Se instalaron sensores de vibración y monitoreo de corriente del motor.

El análisis detectó un aumento en el espectro de vibración dos semanas antes de la falla. El rodamiento se reemplazó en tiempo y forma. Resultado: un paro de emergencia evitado por año, menos pérdida de producción y retorno en menos de un año.

Caso B — Planta de agregados con múltiples colectores

Un productor tenía tres colectores sin control centralizado, lo que causaba flujos desbalanceados y fallas prematuras de filtros. Un gateway IoT consolidó lecturas de presión diferencial y habilitó limpieza bajo demanda.

El análisis mostró que un compartimiento se limpiaba en exceso y otro quedaba corto. Tras balancear y cambiar a limpieza por presión diferencial, la vida de los filtros aumentó un 30 % y el consumo energético del ventilador disminuyó.

Caso C — Planta de acabado de metales: se evitan emisiones

Una planta usó monitores de partículas integrados a un tablero IoT. Un fin de semana, el sistema detectó un aumento súbito de partículas a la salida y envió alertas.

El acceso remoto mostró una válvula de diafragma trabada. La intervención rápida evitó una violación de permiso, multas y dejó un registro auditable del evento y su corrección.

— ¿Cómo evitar sobrecarga de datos y falsas alarmas?

Comienza con pocos KPI relevantes y usa umbrales escalonados: informativo, “atender pronto” y crítico. Combina señales para reducir falsos positivos (por ejemplo, aumento de presión diferencial y más ciclos de pulso antes de marcar cambio de filtros). Revisa periódicamente la configuración de alarmas con operaciones y mantenimiento. Muchas plataformas ya incluyen plantillas optimizadas para colectores.

— ¿Es necesario usar IA o aprendizaje automático para obtener valor?

No. Las reglas y análisis de tendencias ya generan mucho valor. La IA agrega beneficios adicionales al detectar correlaciones complejas y acelerar el diagnóstico, pero muchas plantas obtienen resultados rápidos con análisis simples y escalan después.

— ¿Quiénes deben participar en un proyecto IoT?

Involucra desde el inicio al equipo de operaciones, mantenimiento, EHS y compras. Incluye a TI/seguridad para acordar la arquitectura y manejo de datos. Un equipo multidisciplinario asegura que las alarmas lleguen a las personas correctas y que el sistema resuelva problemas reales.

— ¿Cómo se mide el éxito después de implementar IoT?

El éxito se mide combinando confiabilidad, cumplimiento y ahorro de costos. La mayoría de las plantas empieza por reducir interrupciones no programadas y mantenimiento de emergencia. En cumplimiento, se observan menos desviaciones de emisiones y tendencias de presión diferencial más estables. También se mide menor consumo energético y tiempos de respuesta más rápidos gracias a tableros en tiempo real.

En el aspecto del cumplimiento normativo, el éxito se refleja en menos emisiones fuera de límite, tendencias de presión diferencial más estables y un mejor historial de cumplimiento de los límites del permiso. El consumo de energía es otro indicador clave, ya que muchas plantas registran un menor uso de kWh cuando los ventiladores y los filtros operan de manera más eficiente. Por último, los equipos miden tiempos de detección y respuesta más rápidos gracias a los tableros en tiempo real, lo que demuestra que el IoT les permite actuar antes y de forma más efectiva.